Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

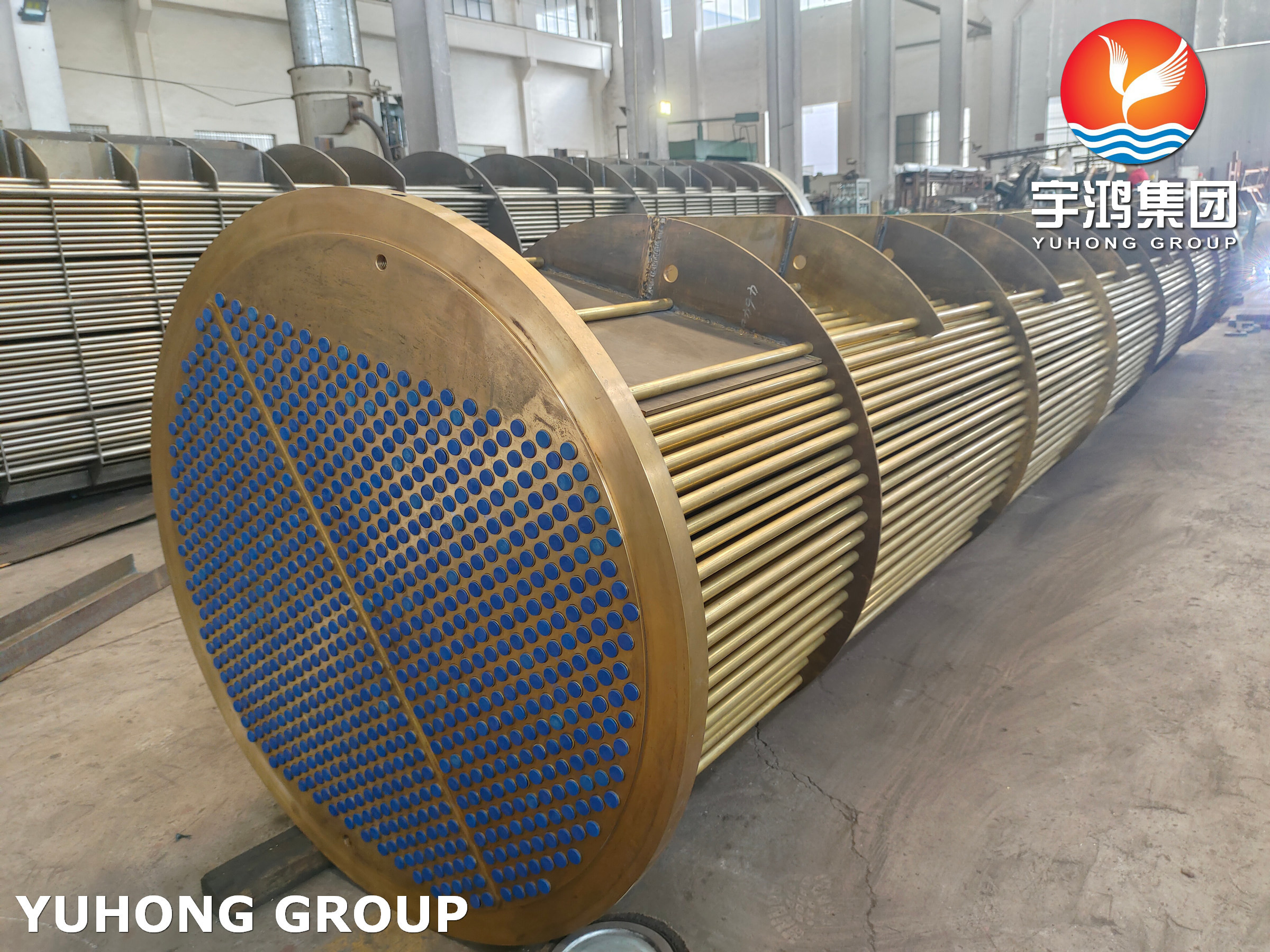

Copper Tube Bundle Shell Tube for Heat Exchangers

Overview

Shell and tube heat exchanger is a type of heat exchanger design. It is the most common type of heat exchanger used in refineries and other large chemical processes for high pressure applications. As the name suggests, this type of heat exchanger consists of a shell (a large pressure vessel) and a bundle of tubes. One fluid flows through the tubes and another fluid flows through the tubes (through the shell), thus transferring heat between the two fluids. This group of tubes is known as a tube bundle and can consist of several types of tubes: plain tubes, longitudinally finned tubes, and so on.

Shell and tube heat exchangers consist of a number of tubes mounted in a cylindrical shell. Figure 1 shows a typical installation in a petrochemical plant. Two fluids can be exchanged for heat, one fluid flows through the outside of the tubes and the other fluid flows through the inside of the tubes. The fluids can be single-phase or two-phase, and can flow in parallel or cross/countercurrent.

Advantages of Copper Tube Bundle

1. Excellent heat transfer: Copper has excellent thermal conductivity, which means that it efficiently transfers heat from one medium to another. This makes copper tube bundles ideal for applications where heat exchange is critical, such as in heat exchangers and condensers.

2. Corrosion resistance: Copper has a natural resistance to corrosion, making it highly durable and long-lasting. This resistance to corrosion helps ensure the longevity and reliability of copper tube bundles, even in harsh environments or when exposed to corrosive substances.

3. High strength and reliability: Copper is a strong and reliable material, which makes it suitable for applications where the tube bundle may be subjected to high pressures or mechanical stress. Copper tube bundles can withstand high internal and external pressures without compromising their structural integrity.

4. Easy to fabricate and install: Copper tube bundles are relatively easy to fabricate, bend, and join. This makes them convenient to work with during installation and maintenance processes. Additionally, copper tube bundles are typically available in a variety of sizes and configurations, allowing for customization based on specific application requirements.

5. Antibacterial properties: Copper has natural antibacterial properties, which can help inhibit the growth of bacteria and other microorganisms. This makes copper tube bundles particularly suitable for applications where hygiene is important, such as in the food and beverage industry or healthcare facilities.

Overall, the advantages of using copper tube bundles make them a popular choice in industrial applications where heat transfer, corrosion resistance, strength, reliability, and ease of fabrication are important considerations.

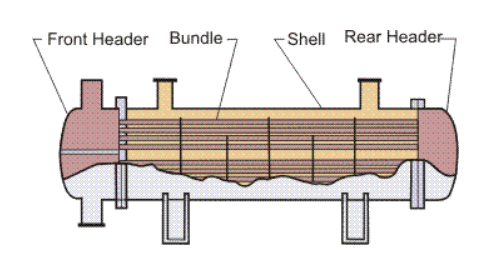

Shell-and-tube heat exchangers consist of four main parts:

Front header - This is where fluid enters the side of the heat exchanger tube. It is sometimes called a fixed header.

Back header - This is where the tubeside fluid leaves the heat exchanger or returns to the front header in a heat exchanger with multiple tubeside channels.

Tube bundle - including tube, tube plate, baffle and tie rod, etc. Secure the bundle together.

Shell - contains tubes.

Common use material for Tube Bundle Heat Exchanger

There are two different of tube bundles:

Straight tubes and U tubes. Depending on specific requirement and application, there are following tube material options:

Carbon Steel Tube : ASTM A179/ASME SA179/179M, ASTM A192, ASTM A333, ASTM A334

Alloy Steel Tubes: ASTM A213 T5, T9, T11, T22, T91

Copper Tubes

Applications

Heat exchangers are widely used in evaporation and drying systems in fossil fuel and nuclear power plants, gas turbines, heating and air conditioning, refrigeration, chemical industry, textile mills.

The main features of shell and tube heat exchangers include: rugged construction, excellent performance, long service life, unique design, smooth operation, can withstand high temperatures, non-corrosive, energy efficient.

Our heat exchangers are widely used in power plants, refineries, manufacturing industries, lube oil coolers, offshore industrial water makers, chemical plants, heating and air conditioning, condensers, nuclear power plants, evaporation and drying systems in textile mills, food and dairy industries and refrigeration systems.