Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

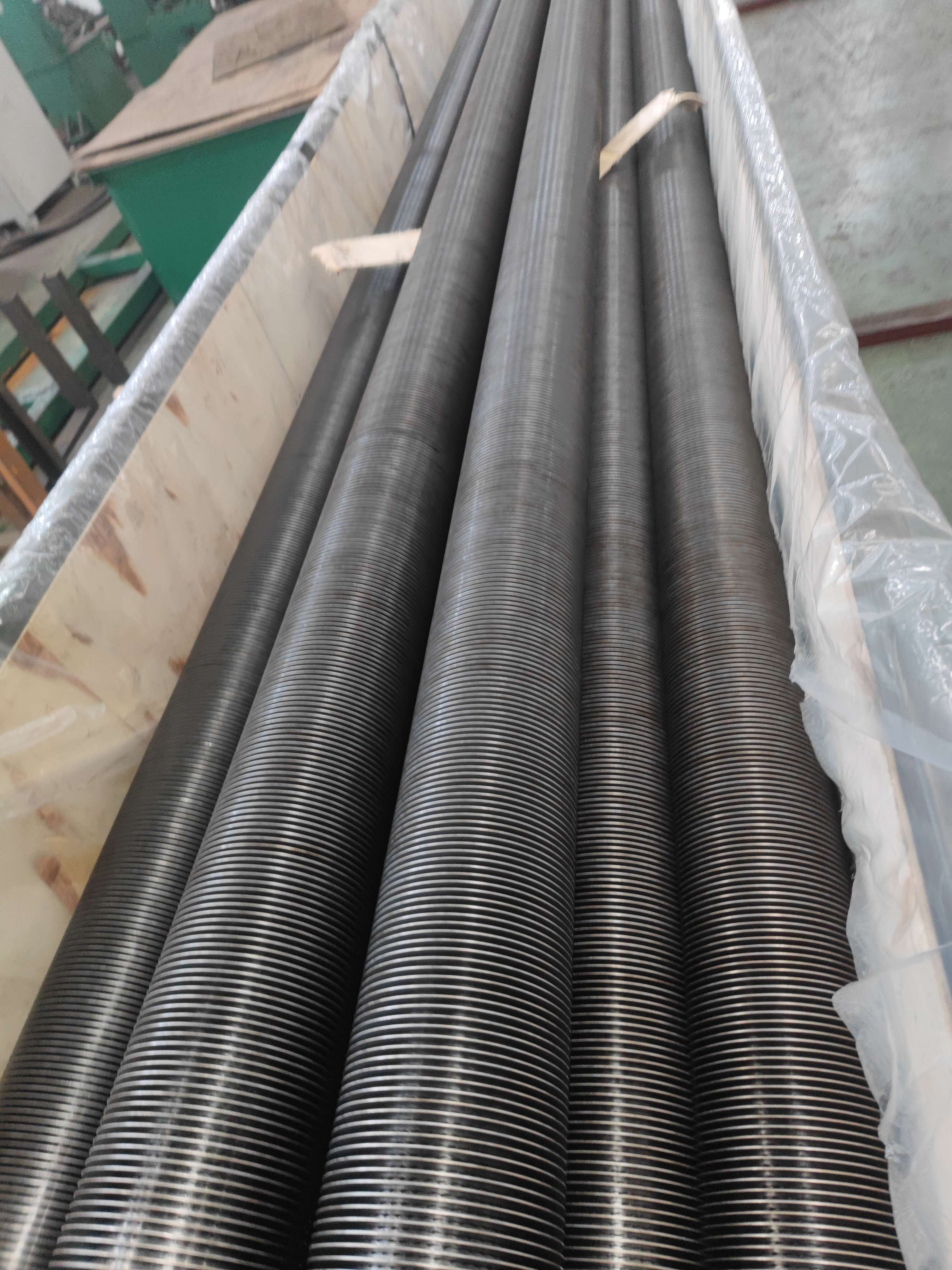

ASME SA106 GR.B Carbon Steel High Frequency Welding Fin Tube For Oil

Description

High frequency welded finned tube, also known as solid finned tube, is made of steel or stainless steel belt directly welded to the surface of the tube by high frequency welding. Can greatly improve the heat transfer efficiency than bare tube. Because the fins are tightly welded to the base tube, these finned tubes are often used in vibration conditions. Fin type has serrated and flat fins.

High Frequency Welded Finned Tube Function

High-frequency welded finned tube is a kind of finned tube, which

is mainly welded by high-frequency welding. It is a new type of

excellent heat dissipation element. High frequency welding finned

tube is welded by high frequency current, the welding method is

reliable and excellent, the weld is small, the radiator surface is

more solid and beautiful.

High frequency welded finned tube is a radiator element commonly

used in finned tube radiator. The high frequency welding finned

tube on the bottom tube of the radiator improves the heat transfer

coefficient of the heat exchanger side and enhances the heat

dissipation effect of the radiator. The excellent heat dissipation

effect makes the finned tube more and more popular.

High frequency welded finned tube adopts high frequency current

welding, which can increase the compactness of radiator and improve

the safety of high frequency welded finned tube radiator during

operation. High frequency welding technology is an improved and

upgraded technology based on basic welding technology, and it is

also a relatively good welding technology.

The better the welding process, the faster the welding speed and

the narrower the weld, the more beautiful the appearance of the

radiator. High frequency welded finned tube is simple and elegant

in appearance and widely used in many fields.

ASTM A106

ASTM A106/ASME SA106 is a standard specification for seamless carbon steel tubes used in high-temperature services. It consists of grades A, B, and C, and the common grade is A106 B. It is not only used for oil and gas, water, pulp and other pipeline systems, but also used for boiler, building, structure and other purposes. ASTM A106 Class B steel pipe is equivalent to ASTM A53 Class B and API 5L Class B in chemical position and mechanical properties, generally made of carbon steel and yiled minimum strength 240 MPa, tensile strength 415 MPa.

A106 Grade B Pipes Chemical Material Composition

| Grade A | Grade B | Grade C |

|---|---|---|---|

Carbon max. % | 0.25 | 0.30 | 0.35 |

Manganese % | 0.27 to 0.93 | 0.29 to 1.06 | 0.29 to 1.06 |

Phosporous, max. % | 0.025 | 0.025 | 0.025 |

Sulfur, max. % | 0.025 | 0.025 | 0.025 |

Silicon, min. % | 0.10 | 0.10 | 0.10 |

Mechanical Properties of Carbon Steel Seamless Pipe ASTM A106

| Grade | Yield Strength | Tensile Strength |

| A106 Gr.B | 240 | 415 |

ASME SA 106 Gr B Pipe Equivalent

| Former | New | ||

|---|---|---|---|---|

Execution | Standard | Material | Standard | Material |

Seamless | ASTM A106 | GRADE B | EN 10216-2 | P265GH |

ASTM A106 Grade B Seamless Pipe Specification

Standards | ASTM, ASME and API, ANSI B 36.10 |

Craft | Cold rolled and Cold drawn |

ANSI Standard | B1.20. |

Grades | ASTM A106 Grade A, Grade B, Grade C |

Type | ERW / Seamless / Fabricated / Welded |

Size | 1/2” NB to 36” NB |

Length | Minimum 3 Meters, Maximum 18 Meters |

Thickness | 3-12mm |

Specialized in | Large Diameter ASTM A106 Grade B Pipe |

Schedules | Schedule 20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

ASME Standard | B36.10M |

Tolerance | Cold drawn pipe: +/-0.1mm |

End | Plain End, Beveled End, Treaded |

Application: