Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

7.5 KW 10M/Min VIGACERO Easy Deck Floor Beam Roll Forming Machine

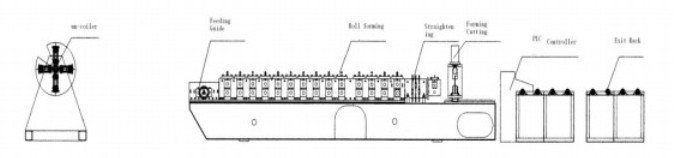

Technological process

Uncoiling—feedingwithguide—Rollforming——Cutting—Products collecting

Technical Data

| Items | Specifications | |

| Material of coil | Material Thickness | 1.5mm galvanized |

| Un Coiler | 3 tons manual | |

| Forming system | Rolling Speed | 10 m/min |

| Roller Stations | About 24 stations | |

| Roller Material | 45# Steel with quenching 60mm shaft

| |

| Main Motor Power | 7.5 kw | |

| Hydraulic cutting Power | 4 kw | |

Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | +-1.5mm | |

| Electrical control system | Electric Source | 220V, 60HZ,3 phase Also can satisfy Customer’s require |

| Control System | PLC (Panasonic) as list in the note | |

| Weight | About 5.5 tons | |

| Way Of Drive | 1 inch single chain | |

| Size of machine | Length 9000mm* Width 600mm* Height 1000mm |

Details of each composition

De-coiler:

3 ton passive decoiler

Cutting way:

(1) Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

(2) Material of blade: CR12 with heat treatment

(3) Length measuring: Automatically

(4) Tolerance of length: + 1.5mm

(5) In order to get the perfect profiles, we recommend the post hydraulic cutting by changing the cutting moulds. It is easy to operate.

Control Box

(1) Voltage, Frequency, Phase: 220V, 60 Hz, 3Phase (this is can depend on customer request)

(2) Automatic length measurement:

(3) Automatic quantity measurement

(4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5) Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7) Unit of length: millimeter (switched on the control panel)

Out table

It adopts welded steel and supported roller to transmit the products.

Size: 2000*1000*1000mm, 2 pieces

Details: