Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

0.7-1.2mm Garage mental Shutter Door Roll Forming Machine , Metal Forming Equipment PLC Control

Sussman Machinery can design every kind of rolling shutter machine to produce roll-up shutter slats from simple security rolling shutters to roll-up shutters designed for storm protection, custom -designed roller shutters, and even fire-proof rolling fire shutter, very fast roll-up shutter or sectional door rolling shutter and so on. We also can add a servo motor and no-stop tracking cutting on the rolling shutters making machine, and the speed can be 25-30m/min. All the data is set up in the PLC computer program(Delta or Mitsubishi for option).

We can supply different kinds of roll forming machines for different shutter doors. If you have your door design, show us your design drawing. A good suggestion can be given out by our enginneer. If you have any idea about your new project, some professional ideas can be gotten from us.

1. This machine is made up of roll forming machine,manual decoiler,cutting machine,PLC computer control and hydraulic system,out put tables.

2. The machine is stable,no noise,no shake.

3. It is one unit, the control box and the hydraulic station for the cutting are all put under the machine frame to save space.

4. The touch screen is hang over, it is not under the floor.

5. When you get the machine,it is no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working.

Working flow

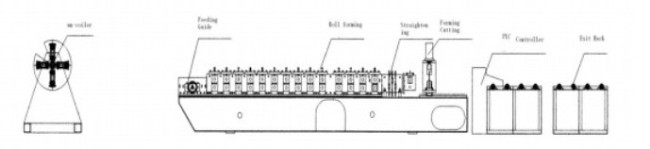

decoiler—→level device—→main roll forming machine—→hydraulic cutting—→ run out table

Profile drawing

Parts of machine

| name | quantity (set) |

| De-coiler | 1set |

| Main roll forming machine | 1set |

| Run out table | 2 sets |

| Control panel | 1set |

The technique data

Materials to form shutter door : 0.7-1.2mm, Galvanized coils

Forming steps: about 12 steps

Material of rollers: GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers: >¢150

Material of main shaft : 45# high quality steel (diameter>¢50)

Chains’ material: 45# steel, high frequency quenching, circular pitch:38.1; number of teeth: 13

Cutting : hydraulic cutting; quenching HRC58-62

Electronic control: Plc control Panasonic Japanese brand

Dimension of machine: 4500mmX500mmX800mm

Drive system: chain drive, 7.5KW main motor power, working speed:12-15m/min;