Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

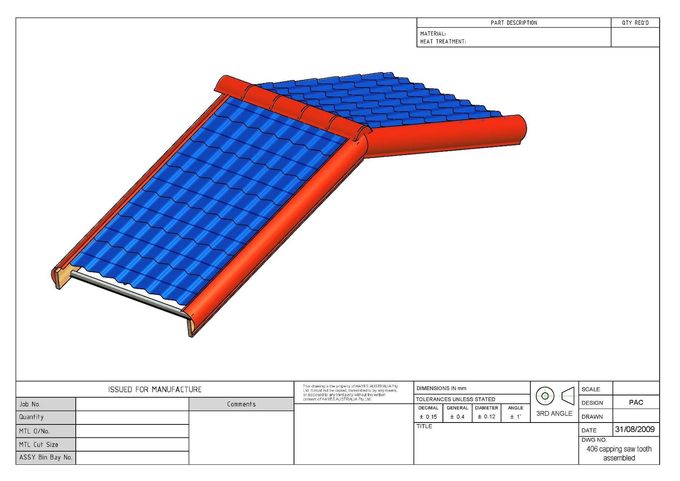

0.3-0.8mm Thickness Ridge Capping Roof Tile Making Machine Roof Sheet Roll Forming Machine

Ridge capping tile is used as the apex join of two sides of the

roof. The roof ridge capoing is a necessary part of any profiled

clad building ,provides a clean,maintenance free, weightless ,

totally weatherproof finish to your roof, it is cost-effective and

labor saving, it can also enhance the aesthetics of any structure.

Roof ridge capping fit primarily to maintain a watertight roof.

Without a ridge capping fitted, the rainwater would run down the

chimney, or the higher area of roof tiles, and just disappear into

the house interior where the chimney rises through the roof.

Metal roofing is a common choice as a roofing material, as it

design to last longer than composite or other similar protective

coverings. The ridge capping tile is installed after all roof

panels,then trim it is in place.

Description of the machine:

Item NO. |

Description |

Offered specification |

| 1.0 | Roll forming machine | |

| 1.1 | Rolling speed | 5-10m/min(not include cutting time) |

| 1.2 | Rolling thickness | 0.42 mm |

| 1.3 | Raw material | 400mm,G550Mpa Hi Tensile Colorbond Steel |

| 1.6 | dimension | 1500×1700×1500(mm) about |

| 1.7 | Effective width | 60mm |

| 1.8 | Roller stations | 16 stations

|

| 1.9 | Roller material | 45#forge steel, coated with chrome |

| 1.10 | Shaft diameter | Φ70mm ,material is 45# forge steel |

| 1.11 | Transmission | By chain 1 inch |

| 1.12 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Tolerance of cutting | 6m+-1.5mm |

| 1.16 | Frame | H type steel |

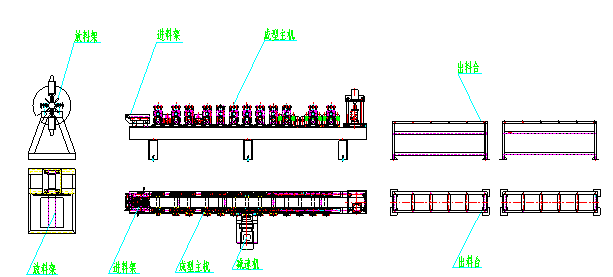

Machine List:

Advantage for Ridge Cap

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Working flow of the Ridge Cap:

Uncoiling—Feedingwithguide—Roll forming—cutting—Products collecting

Notes:

1. The delivery term for the above equipment is FOB SHANGHAI

2. The whole producing plant has the CE certificate approved

3. We offer a warranty period of 1year for all of our machines.

4. Our after-sales services will include factory process designing, equipment Installation coaching, test running the machines, and training of your operation personnel.

Drawings:

Application: