Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Type-688 Floor Deck Automatic Roll Forming Machine with High Efficiency and High Quality

| Item NO | Description | UnitType | RF-DF |

| 1 | Steel Thickness | mm | 0.75-1.5mm |

| 2 | Forming Speed | m/min | 0-12 |

| 3 | Roller stands | stand | 28 |

| 4 | Roller Material | high-grade 45# steel | |

| 5 | Shaft diameter | 90 | |

| 6 | Main Motor Power | Kw | 15kw |

| 7 | Hydraulic cutting Power | Kw | 5.5 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply | 380V, 50HZ,3 phase | |

| 10 | Tolerance | mm | 1.5 |

| 11 | Material of cutting | Cr12 | |

| 12 | Control system | PLC Panasonic with touch screen |

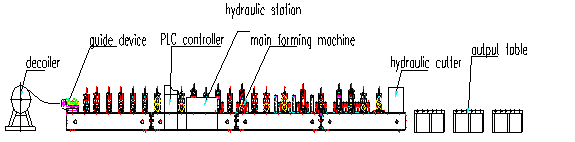

echnological process

Uncoiling—Feeding&Leveling ---Roll forming—Cutting—Products collecting

The profile

The profile is designed according to the client requirement.

Type-688 Floor Deck Roll Forming Machine The machine has the advantages of high efficiency, high quality and

low energy consumption, and can produce finished products in a

short time, which greatly reduces the production cycle and

facilitates early profitability. The machine has been certified by quality system and has won the

recognition and support of the new and old customers. At the same

time, our company can provide a more perfect service system,

ensuring that before sale and after sale, it can bring high-quality

experience to customers. |

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can

produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled

technicians available across the world.We need your machines

running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to

CangZhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai

HongQiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12 months,if the broken parts

can't repair,we can send the new parts replace the broken parts

freely,but you need pay the express cost yourself.if after warranty

period,we can through negotiation for to solve the problems,and we

supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich

experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade

company is just for exporting various types of cold roll forming

machines.