Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

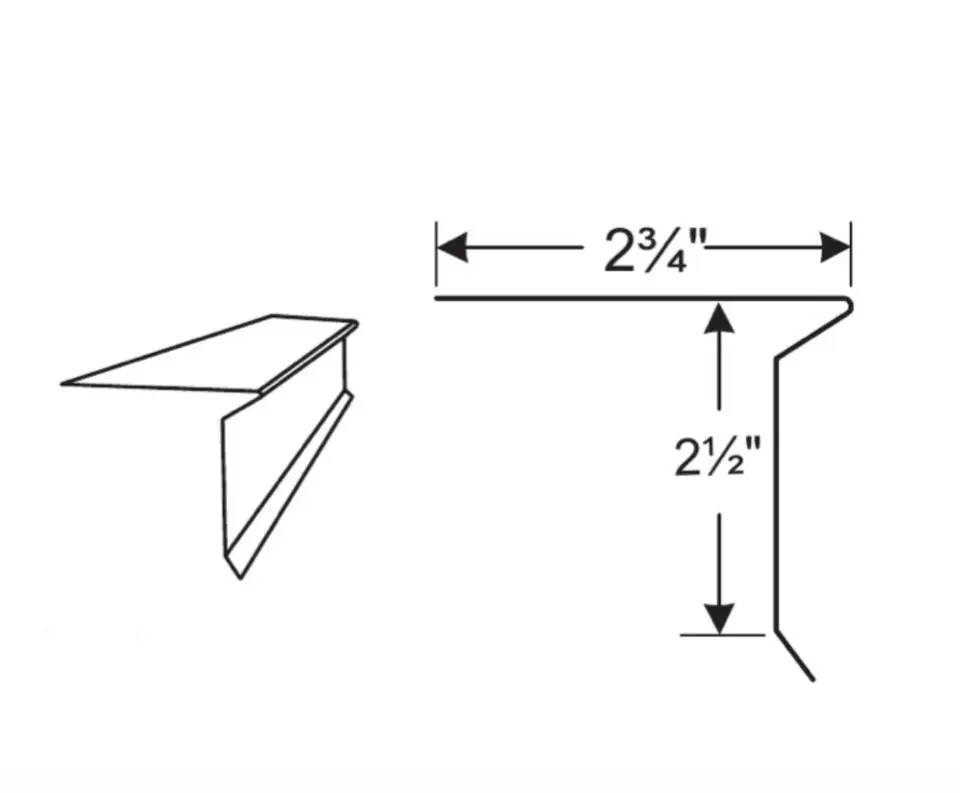

1.5''*1.5'' Flashing Drip Edge Roll Forming Machine Metal Sheet Roof Eave Trim

Drip edge is a metal flashing that is installed at the edge of the roof to help direct the flow of water away from the fascia and to protect the underlying roofing components. Drip edge overhangs the sides of the roof and has a small metal flange that is bent away from the fascia.

Drip edge should be installed 1.5” to 2” away from the edge of the fascia to ensure the water drips into the eavestrough.

Without a drip edge, water may end up beneath the shingles and may cause damage to various parts of the home. Though your home may not originally have had a drip edge installed, it is now required by most building codes across North America to protect homes from damage.

Technical Data:

| Items | Specifications | |

| Material of coil | Material Thickness | 0.4-1.0mm Thickness |

| Forming system | Rolling Speed | 0-10 m/min( without the cutting time) |

| Roller Stations | About 16 stations | |

| Roller Material | 45# Steel with quenching 60mm shaft

| |

| Maim Motor Power | 5.5 kw | |

| Hydraulic cutting Power | 4 kw | |

| Bearing | Rubber sealing bearing | |

Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRB85-95 | |

| Tolerance | +-1.5mm | |

| Cutting way | Stop cutting | |

| Electrical control system | Electric Source | 220V, 60HZ,3 phase Also can satisfy Customer’s require |

| Control System | PLC Delta | |

| Inverter | Delta | |

| Weight | About 2.5 tons | |

| Way Of Drive | 1 inch single chain | |

| Size of machine | Length 3000mm* Width 800mm* Height 500m | |

| MOTOR | Under the frame of the machine |

Machine List:

| 3 ton passive de-coiler | 1 set |

| Main roll forming machine | 1 set |

| Cutting device | 1 set |

| PLC Control box | 1 unit |

| Hydraulic station | 1 unit |

| Out table | 1 unit |

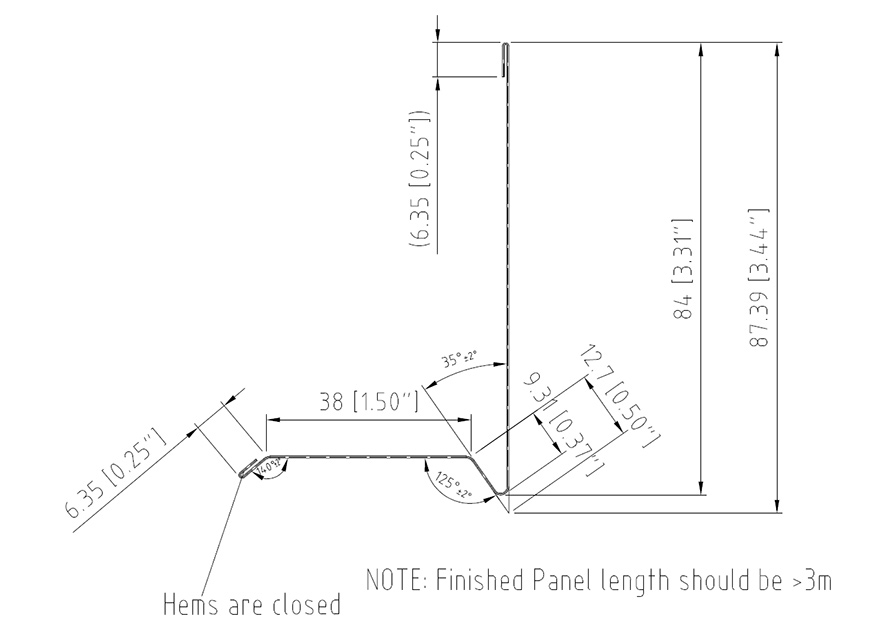

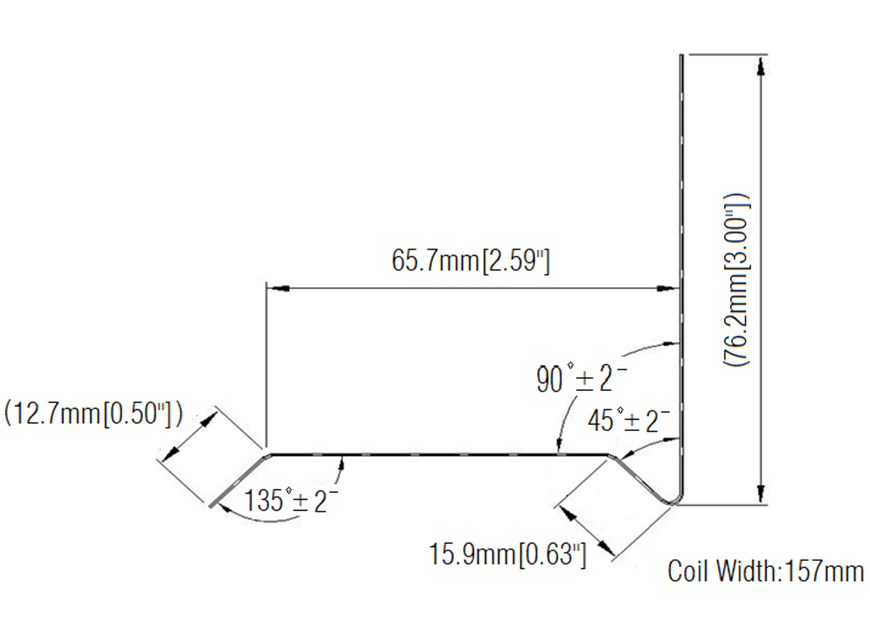

Profile Drawing:

Samples:

Application:

(1) The edge of a roof from which rainwater drips into a gutter or away from the structure.

(2) The metal or wood strip that stiffens and protects this edge.

Metal trim is a must for most pole barns. It adds protection, dimension and personality to your structure.

Eaves and drip flashings are used on overhangs, sides or ends and on roof edges to protect the façade from all weather conditions. They provide support for shingles and form a roof drip edge that helps direct water into gutters or away from exterior walls.