Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

0.7-1.2mm Thickness Metal Roof Sheet Making Machine Beam Standing Roll Forming Machine

Flush-Panel Soffit – FP10 is a commercial grade soffit panel system

that provides a flush, aesthetic appearance upon installation.

The product is an integral interlocking system by design which

installs in one direction from a given starting point.

Standing Beam Bottom Technical Parameter

1. Steel Sheet Thickness: 0.7-1.2mm (depend on requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching,

circular pitch: 38.1, number of teeth:13

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 5 ton passive decoiler

6. Forming Speed: 0-12m/min

7. Roller Groups: 16 stations

8. Roller Material: 45# steel, high frequency quenching treatment,

HRC58-62

9. Material: galvanized steel, color coated steel

10. Principal Axis: 45# high grade steel with quenching treatment

11. Main Motor Power: 7.5 Kw

Standing Beam Main Components

| S.N | Equipment name | Quantity |

| 1. | 5T passive un-coiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 3. | Main roll forming machine 18 stations

| 1 set |

| 4. | Hydraulic cutting | 1 set |

| 5. | Control system (including control box) | 1 set |

| 6. | Out tables | 2 sets |

| 7. | Hydraulic station | 1 set |

| 8. | Seamer device | 1 set |

Advantage for Standing Beam

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

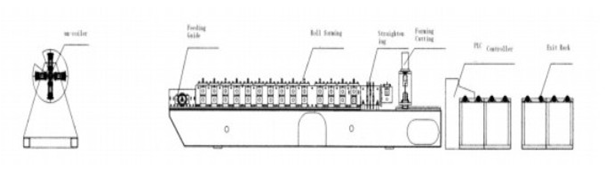

Working Flow of Standing Beam

Decoiler----Feeding and Leveling---Roll forming---Cutting---Run out

tables

Profiles of Standing Beam

Company Introduction

Sussman Machinery (wuxi) Co., Ltd. is a comprehensive enterprise

integrating production, sales and services. We are mainly engaged

in providing machineries and equipment. Owing to a professional

teamwork, we are experienced in manufacturing, import and export,

customers' design, installation and test, technical solution and

after-sale services. We have shipped out our machines to more than

50 countries, and keep good business relationships with a large

amount of worthy customers, contributing to our great business

records and reputation.

Customes Visiting

Loading Pic.