Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Double Layer Roof Panel Wall Panel Roll Forming Machine 0.3-0.8mm

Thickness Galvanized Steel

1. Technical Parameter

| Number | Items | UnitType | RF-DL |

| 1 | Steel Thickness | mm | 0.3-0.8mm Colored Steel/ Galvanized Steel Coil |

| 2 | Forming Speed | m/min | About 8-15 |

| 3 | Roller stands | stand | Upper layer is about 20 stations Lower layer is about 18 stations |

| 4 | Roller Material | mm | 45# steel, coated with chrome |

| 5 | Shaft material and diameter | mm | Ф76 45# steel, coated with chrome |

| 6 | Main Motor Power | Kw | 7.5 |

| 7 | Hydraulic cutting Power | Kw | 4 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply | 380V, 60 Hz, 3Phase | |

| 10 | Tolerance | mm | +-1.5 |

| 11 | Material of cutting | Cr12Mov HRC58-62 | |

| 12 | Control system | PLC with touch screen | |

| 13 | Main machine weight | T | 10T |

2. Machine List

5 tons passive de-coiler | 1 set |

Guiding Platform | 1 set |

| Double pre-cutting device | 1 set |

Main roll forming machine | 1 set |

Hydraulic cutting machine | 1 set |

PLC Control box | 1 unit |

Hydraulic station | 1 unit |

Passive Out table | 2 units |

Safety cover | 1 unit |

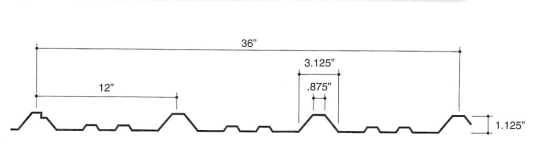

3. Profile Drawing

This double roof/wall panel machine that can form AG and R panels.

Minimum Coil width for AG panel is 1,038.22mm and R panel minimum

is 1,079.5mm finished measurement for both panels is 914.5.

Thickness range 0.360mm-0.666mm.

4. Main Features

1.This double roll forming machine can produce two different

profiles with one machine, sharing same machine base frame,

un-coiler, PLC control system, which can much save of your cost.

2.More reasonable forming process design; More roller steps with

competitive price.

3.The whole line consists of un-coiler, double pre-cutting system,

feeding system, roll forming machine with protect guarding cover,

post-cut device, PLC control system, and so on.

5. Machine Photo

6. Packing and delivery

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will

mpaint the coil on the roller and shaft, in case the roller and

shast got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts,

and fix all the parts into container by the steel wire rope, and

ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container