Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Galvanized steel 0.36 Mm-0.6 Mm Thickness 914mm Width AG And R

Panel Double Layer Roof/Wall Panel Roll Forming Machine

1. Technical Parameter

| Number | Items | UnitType | RF-DL |

| 1 | Steel Thickness | mm | 0.3-0.8mm Colored Steel/ Galvanized Steel Coil |

| 2 | Forming Speed | m/min | About 8-15 |

| 3 | Roller stands | stand | Upper layer is about 20 stations Lower layer is about 18 stations |

| 4 | Roller Material | mm | 45# steel, coated with chrome |

| 5 | Shaft material and diameter | mm | Ф76 45# steel, coated with chrome |

| 6 | Main Motor Power | Kw | 7.5 |

| 7 | Hydraulic cutting Power | Kw | 4 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply | 380V, 60 Hz, 3Phase | |

| 10 | Tolerance | mm | +-1.5 |

| 11 | Material of cutting | Cr12Mov HRC58-62 | |

| 12 | Control system | PLC with touch screen | |

| 13 | Main machine weight | T | 10T |

2. Machine List

5 tons passive de-coiler | 1 set |

Guiding Platform | 1 set |

| Double pre-cutting device | 1 set |

Main roll forming machine | 1 set |

Hydraulic cutting machine | 1 set |

PLC Control box | 1 unit |

Hydraulic station | 1 unit |

Passive Out table | 2 units |

Safety cover | 1 unit |

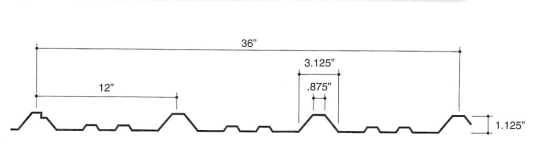

3. Profile Drawing

This double roof/wall panel machine that can form AG and R panels.

Minimum Coil width for AG panel is 1,038.22mm and R panel minimum

is 1,079.5mm finished measurement for both panels is 914.5.

Thickness range 0.360mm-0.666mm.

4. Main Features

1.This double roll forming machine can produce two different

profiles with one machine, sharing same machine base frame,

un-coiler, PLC control system, which can much save of your cost.

2.More reasonable forming process design; More roller steps with

competitive price.

3.The whole line consists of un-coiler, double pre-cutting system,

feeding system, roll forming machine with protect guarding cover,

post-cut device, PLC control system, and so on.

5. Machine Photo