Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Galvanized Steel Top Hat Channel Omega Profile Roll Forming Machine With 12 Stations

Furring channel machine is used to plaster board, gypsum board and other decorative finishes lightweight board made of non-load-bearing walls and roof of the building style decoration, a variety of decorative building roof shape, inside and outside the building wall and ceiling scaffolding base material.Products made by this machine are suitable to use in hotels, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration settings, roof and other places.

Material for this machine is galvanized steel plate, snowflake

plate and cold steel plate,we can according to customer design,

manufacture different specifications of cold-formed.

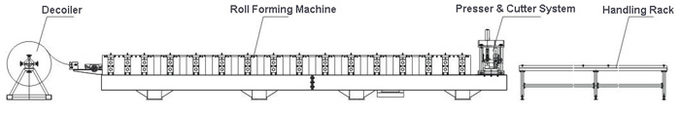

The machine includes decoiler, feeding and leveling device, main forming machine, hydraulic cutting device, the frequency converter controls the motor speed, the PLC system controls length and quantity automatically. Our produced profile meet ISO, CE , UL standards, and our machine is applied to steel structure, industry or home.

Product Description

Decoiler: 3 ton manual

Roll Forming Machine: About 12 station

Rolling Speed: 0-10m/min

Main Motor: 7.5kw

Hydraulic Power: 4kw

Output Table: one manual 6 meter output table

Machine Technical Parameter

| Items | Specifications | |

| Material of coil | Material Thickness | 0.4-1.2mm |

| De-coiler | Weight | 3 ton manual |

| Forming system | Rolling Speed | 0-10m/min |

| Roller Stations | About 12 stations forming | |

| Roller Material | Gcr15 Steel with quenching | |

| Shaft Material | 45# Steel | |

| Main Motor Power | 7.5 kw | |

| Hydraulic cutting Power | 4 kw | |

| Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | +-1.5mm | |

| Cutting blade | 1 set of cutting blade | |

| Electrical control system | Electric Source | 380V, 50HZ |

| Control System | PLC with touch screen Japanese Panasonic and Yaskawa Brand | |

| Weight | About 3.5 tons | |

| Way Of Drive | 1 inch single chain | |

| Size of machine | Length 5500mm* Width 600mm* Height 800m |

Main Components

| Main Components | |

| 3 ton passive de-coiler | 1 set |

| Feeding with guide | 1 set |

| Main roll forming machine | 1 set |

| PLC control system | 1 unit |

| Hydraulic station | 1 unit |

| Stop cutting device | 1 unit |

| Safety cover | 1 unit |

| Out table | 1 unit |

| Spare parts | 1 package |

Working Flow of Roll Forming Machine

feeding with guide—Roll forming——Cutting—Products collecting

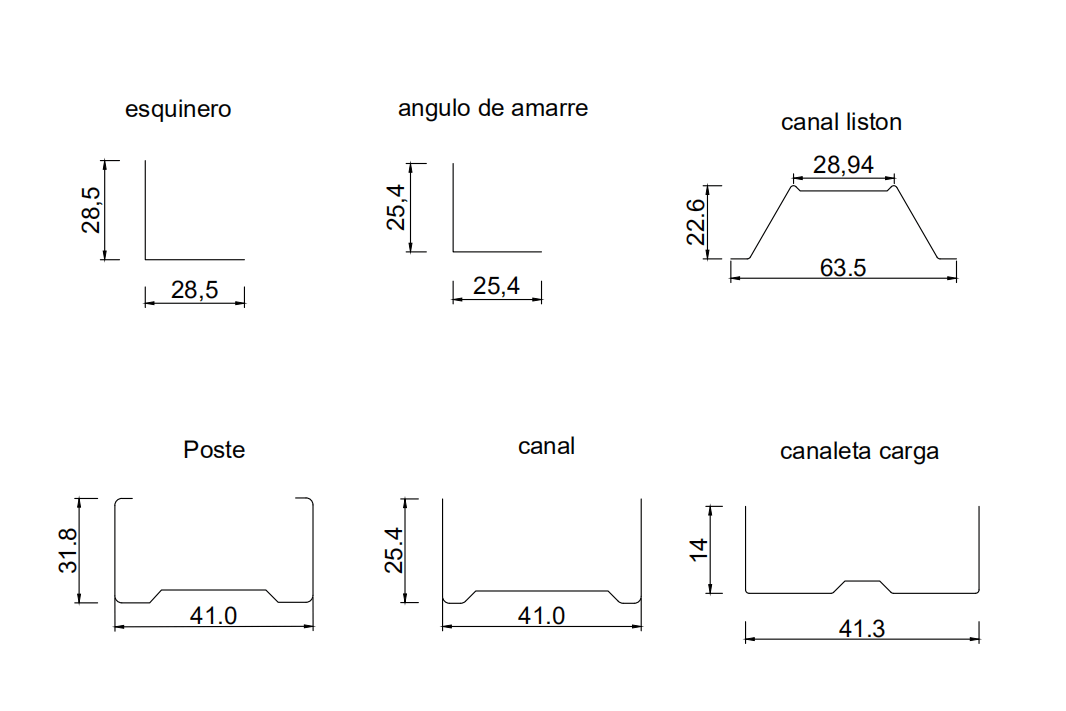

Standard Profile and Drawing Of Product

Product Images

Application