Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Automatic PLC Control 0.4-0.7mm Thickness Glazed Tile Metal Roofing Roll Forming Machine

The finished products are widely used in garden-like factories, tourist scenic spots, pavilions and pavilions, hotel villas, exhibition halls, resorts, resorts and so on. It has many advantages, such as beautiful scenery, Home and other architectural and outdoor decoration.

Product Description

Color Steel Sheet Thickness: 0.4~0.7mm Color Sheet

Color Steel Sheet width: 1000mm

Roller Stations: 16 stations

Way Of Drive:1.2 inch single chain

Roller Material: 45# forge steel, coated with chrome

Shaft Material and DIA:¢76mm, material is 45# forge steel

Main Motor Power: 7.5kw

Press parts:

Type:Hydraulic

Hydraulic Station Power: 5.5kw

Size of the press parts: 2000*1800*1500mm

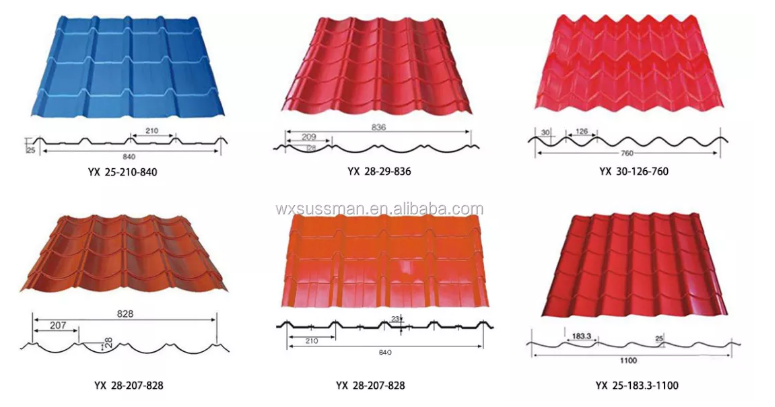

Profile Drawing

Maintance and the service of the machine

Daily maintenance with meticulous care plays an important part in

extension the equipments’ operation time and the quality of rolling

plank. Therefore, please do the following things in your daily

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil

before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving

chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work

outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when

you use next time.

4. If the equipment does not use for long time, you should use

plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to

the request

6. Usually look into hydraulic station and the oil quantity of

deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry

environment, such as damp. Rain should continue to work after

drying.