Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

CE Certificate 13 Stations Main Channel Roll Forming Machine for Galvanized Steel

Main technique of the roll forming machine:

1,Running material: Galvanized steel Thickness – 0.27-1mm

2,Forming speed: 12-15m/min

3,Forming steps: 13 steps

4,Roller material: Fine steel precision work processing of Gcr15,Roller datum roller diameter φ120

5,Material of principal axis: Fine steel modulation processing of 45

6,Sprocket wheel: 45 steel high-frequencies quench; distance 25.4. Quantity: 13pcs

7,Motor power: 7.5 KW

8,Cut-off system: Adopts hydraulic pressure drive, cut off after forming.

9,Hydraulic system electrical machinery power: 4KW

10,Hydraulic system pressure: 10Mpa

11,PLC Control system: Brand of Panasonic ; Touch screen is brand of Beijing huade, Encoder is Japanese Omron brand; the Inverter is Siemens brand

12,Rack row of work place: Steel rack of 446X199H; Detachable wall plate type row of work place

13. Overall Dimension of the main forming machine: 6000mmX700mmX900mm

14, Total weight: 3 ton approximately

15. Un-coiler: 3 Ton capacity of manual un-coiler

16. the punching press machine for the holes

17. Power supply: 380V 50HZ, 3 phase

Applications

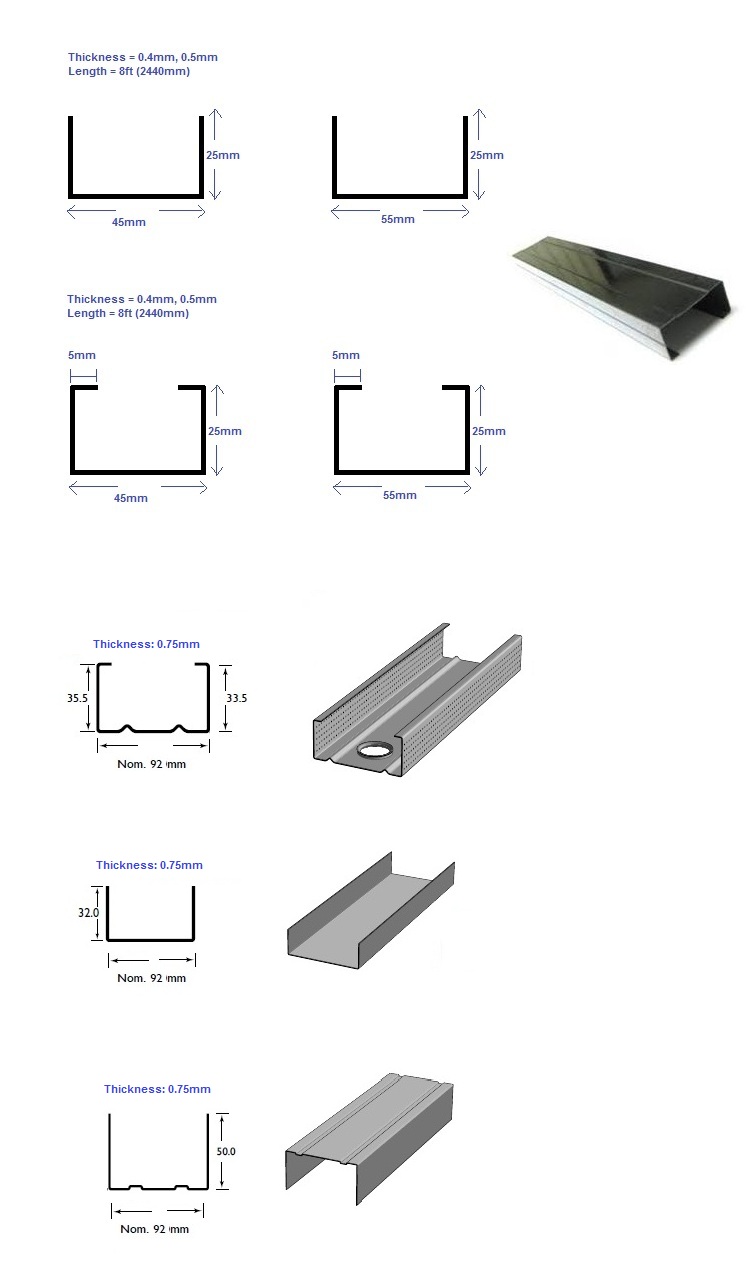

Metal stud and track, steel stud and track, c stud, u runner, u track, furring channel, roof ceiling batten, roof truss, c truss, light weight steel truss...

Main Channel Working Flow

De-coiler—→feedingwithguide—→main roll forming machine—→cutting—→ run out table

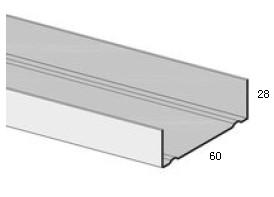

Profile Drawing OF Main Channel Roll Forming Machine

Main Components

| Machine list | 3 ton passive de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic station | 1 unit | |

| Stop cutting device | 1 unit | |

| Safety cover | 1 unit | |

| Out table | 2 units |

Advantage for Main Channel Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Details of each composition:

Cutting

(1) Cutting after forming: Cut the sheet after roll forming to required length

(2) Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

(3) Material of blade: CR12with heat treatment

(4) Length measuring: Automatic length measuring

(5) Tolerance of length: 10m+/- 2mm

Main Channel Forming Machine Pictures