Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

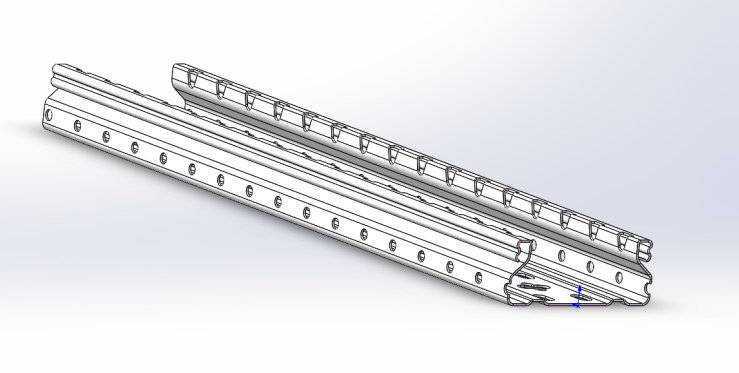

Steel Guide Rail Roll Forming Equipment Chain Drive Cassette Type CE Approved

This machine can make different profiles by change cassette,including decoiler, roll forming system, hydraulic cutting system,control box system and out put tables,etc.

1.Technical Parameter

Raw material: Galvanized steel or blank steel

Material thickness 0.8-1.5mm

Working Speed: 12 meters / min

Forming Steps: 22 stations

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

Driven system: Chain drive

Main Power with reducer: 11KW WH Chinese Famous

Cutting: Hydraulic Cutting Cr12mov

Material of Cutting Knife: Cr12Mov, Quench HRC58-62

Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

The whole machine is controlled by industry computer-PLC.

PLC--Panasonic with touch screen, Japan English and Chinese Language

Touch Screen--Panasonic Japan

Encoder--Omron, Japan

Electric parts--Schneider

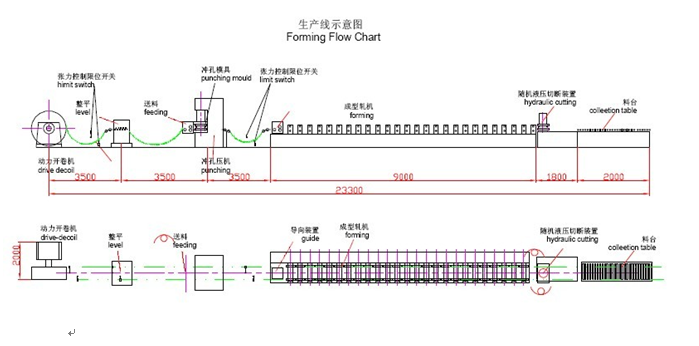

2. Working Flow

3. Machine Components

3T hydraulic un-coiler | 1 set |

Leveling device 300mm | 1 set |

Servo feeding device 300mm | 1 set |

Press machine | 1 set |

Main roll forming machine | 1 set |

PLC control box | 1 unit |

Hydraulic station | 1 unit |

Punching die set | 1 set |

Cassettes | 1 set |

Out tables | 2 units |

4. Technique data

De-coiler

Diameter: 460-520mm expansion.

Expansion: hydraulic

Capacity: 3000kg per mandrel

Max Coil Width: 500mm

Drag tension brake with variable brake tension adjustment valve

Leveling device

1. 7 rolls leveling, 3 rolls up and 4 rolls down

2. Diameter is Ø 80mm, chrome and HRC60 heat treatment to secure

the smooth surface

3. Leveling Raw Material thickness:1.5-3mm

4. Max Leveling Raw Material width: 300mm

Feeding device

Feeding Servo feeding motor: 2.9kw (Yaskawa, Japanese Brand)

Description: servo feeding can control the punching distance in

precision, controlled by PLC, and the feeding tolerance can

be+-0.5mm, the servo motor can control the speed, and can accept

the input signal, and react quickly, and performance well, the

touch screen can display the rotating speed, the length and the

quantity, it can be controlled by the manual and auto modes.

Press machine

Series JH21-63

Brand name: Yangli

JH21 series press machine description:

JH21series open back press with dry clutch and hydraulic overload

protector

◆ Welded body with steel plate and high intensity.

◆ Main motor is made by Siemens.

◆ Adopts combined pneumatic friction clutch and brake.

◆ Cluster gear adopts the flooding oil lubrication.

◆ Six-face rectangle lengthen guide; JH21-315B/400B adopts

eight-face lengthen guideway.

◆ Equipped with hydraulic overload protecting device.

◆ JH21-25/25B/45 adopts manual shut height adjustment,among these

types JH21-25/45 adopts scale display and JH21-25B with digital

display.JH21-63 and above type adopts electric shut height

adjustment with digital display.

◆ JH21-45 can equip with die set height adjustment motor, the value

will be displayed by digital.

◆ JH21-25B, JH21-45 and above type equipped with balance cylinder.

◆ Duplex valves imported.

◆ Electric compelling grease lubrication system.

◆ Balancing cylinder adopts manual lubrication system.

◆ One set of blowing device.

◆ Controlled by PLC with international brand.

◆ Buttons, indicators, AC contactors, air circuit breakers and

other controlling devices are imported from international brand.

◆ Equipped with optional air cushion device, automatic feed shaft

and photoelectric protector,which can used to work with various

automatic equipments.

5. Machine profile reference

6. Our Exhibition

We will attend PERU ARCON Expo

Booth Number:E126

Time:4th-7th,July,2018

Address: Lima Jokey Plaza International Exhibition Center