Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

metal stud and track roll forming machine

Main parameter of drywall metal stud machine :

| Material hardness | 550mpa-350mpa |

| Loading capacity | 1.5T |

| Uncoiling width | 300mm |

| Inner diameter | 450-550mm |

| Processing material | GI |

| Material thickness | 0.4-0.8mm |

| Frame thickness | 25mm |

| Drive mode | gear |

| Forming speed | 20m/min |

| Formed width | 46.5mm |

| Material of shafts | 45#steel with tempering of keel roll forming machine |

| Diameter of shafts | φ40mm |

| NO. of rollers | 10 rollers |

Uncoiler

| Usage | It is used to support the steel coil and uncoil it in a turnable way. Passive uncoil pulled by roll forming system

|

| Loading capacity | 1.5T |

| Uncoiling width | as you need |

| Inner diameter | 450-550mm |

Usage:Put the raw material(steel plate) through the beach to manufacture and process,

it can guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate angle iron.

| Main parameters of metal stud and track roll forming machine | ||

| 1 | Length of the main part | about 5400*1400*1500mm |

| 2 | Weight of main part | 2.5T |

| 3 | Voltage | 380V/50HZ 3Phase |

| 4 | Roller fixer | middle plate |

| 5 | Frame | 350H steel |

| 6 | Drive mode | gear |

| 7 | Material of rollers | 45#steel, surface hard chromium plating |

| 8 | Material of shafts | 45#steel |

| 9 | Diameter of shafts | φ 50mm |

| 10 | Number of rollers | 12 rollers |

| 11 | Main power | 5.5kw |

| 12 | Material of mould | Cr12 quenched |

| 13 | Power supply | hydraulic power |

Cutting device

The cutting blade controled by the hydraulic system

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

| Material of blades | Cr12 quenched |

| Power supply | hydraulic power |

| Components | It contains one set of blade, one hydraulic tank and one cutter machine. |

| Power | 5.5KW |

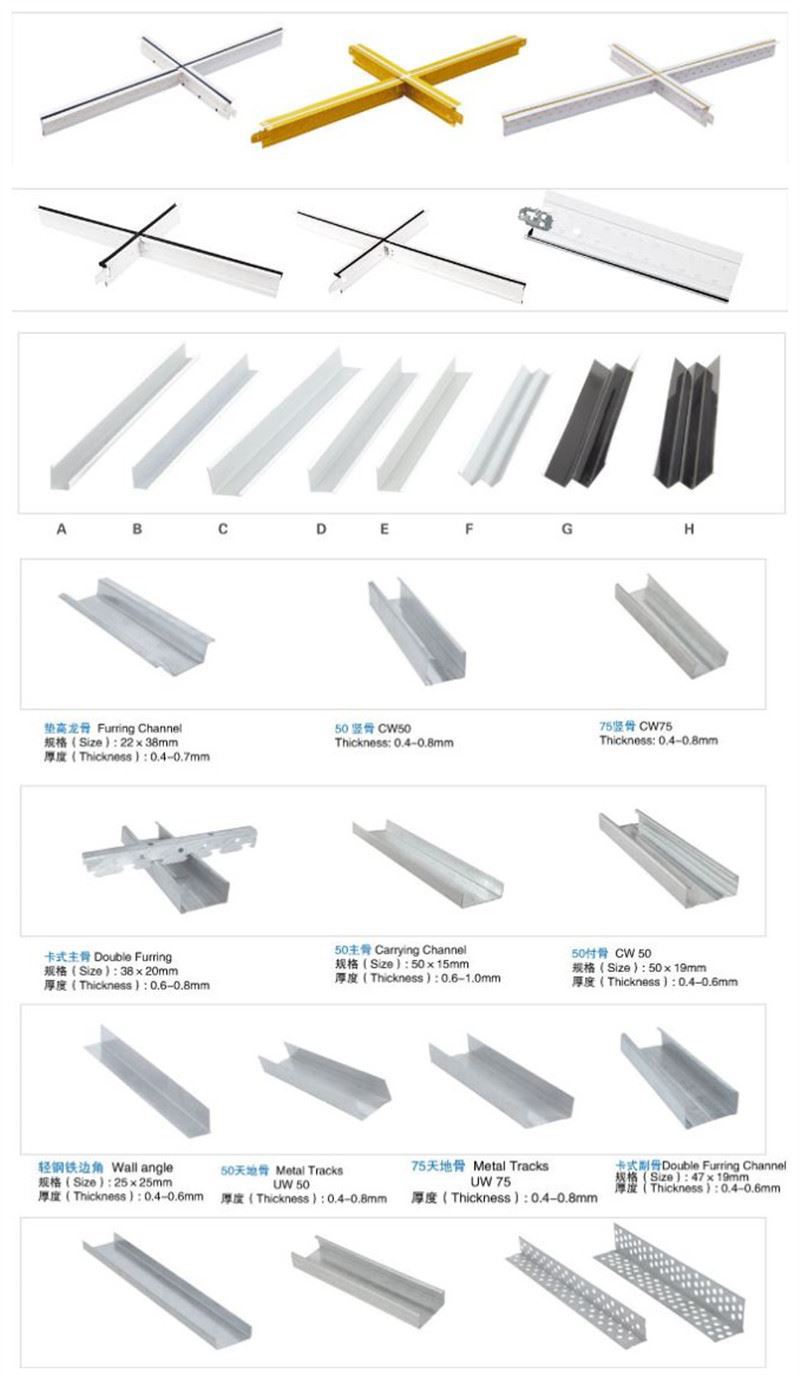

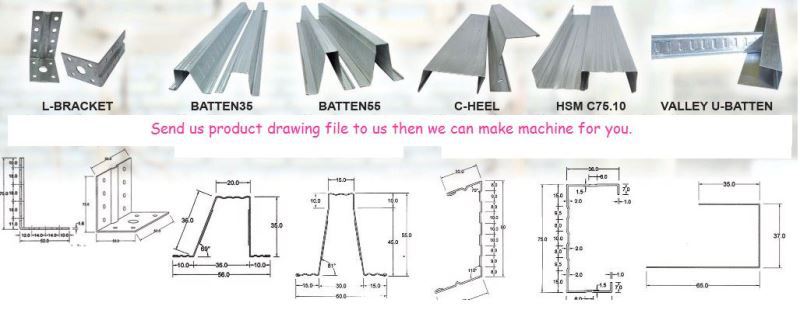

The product we produce:

the machine naked in the container or packing as your required.

Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit

Guarantee: One year, and we will provide the technical support for the whole life.