Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

1.Technical Parameter

Item NO. |

Description |

Offered Specification |

1.0 | Roll forming machine | |

1.1 | Rolling speed | 10-15m/min |

1.2 | Rolling thickness | 0.3mm-0.6mm |

1.3 | Raw material | Galvanized steel sheet |

1.4 | dimension | 3500*1600*1500mm |

1.5 | Effective width | 60mm |

| 1.6 | Roller stations | 20stations One stage for embossing

|

1.7 | Roller material | 45#forge steel, coated with chrome |

1.8 | Shaft diameter | Φ70mm ,material is 45# forge steel |

1.9 | Transmission | By chain 1 inch |

1.10 | Material of chain | 45# forged steel with frequency quenching, 12A |

1.11 | Material of cutting | Cr12Mov with quench HRC58-62° |

1.12 | Tolerance | 6m+-1.5mm |

1.13 | Frame | H type steel |

2.Main Components

Serial No. |

Commodity & Description |

Quantity |

1 | 3 tons manual de-coiler | 1 set |

2 | Infeed guiding | 1 set |

3 | Main roll forming machine | 1 set |

4 | Straighten device | 1 set |

5 | Hydraulic cutting equipment | 1 set |

6 | Output table | 2 sets |

7 | Main drive | 1 set |

8 | Hydraulic system | 1 set |

9 | Controlling system (including cabinet) | 1 set |

10 | Downpipe elbow forming machine | 1 set |

11 | seaming machine | 1 set |

| ||

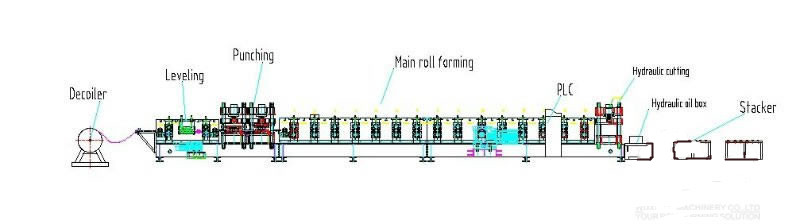

3.Working Flow of Roll Forming Machine

A. Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B. Servo Feeding

Applicator............................................To feed the

material accurately

C. Hydraulic/Press

Punching...........................................To punch as

requirements

D. Roll Forming

Unit.........................................................To

roll form as requirements

E. Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F. Output

Table................................................................Support

the finished products

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

4. Advantage for Roll Forming Machine

1). Factory Reasonable Price

2). High Best Quality

3). 12 Months Warranty

4). More Than 10 Years Experience

5). Durable

6). Afrer-sales service

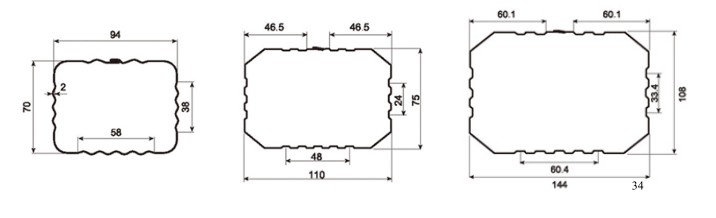

5. Standard Profile of Product

6. Photo Gallery

7. Loading picture

8. Company Profile

Sussman Machinery (wuxi) Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it always designs and produces various type profile

of roll forming machine.

The main products of factory is Roller shutter door, PU sandwish panel line, pre-painted steel forming machine, Racking roll forming machine, the cable tray roll forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down

Pipe forming machine, the whole carriage plate for car beam unit, Steel storage unit, etc. The products

are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas and other

construction projects, Our factory can meet the construction enterprises, automobile industry, Iron and

steel production enterprises' growing demands.