Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

High Speed Galvanized Steel Warehouse Pallet Rack Roll Forming

Machine , Box Beam Making Machine

Technical Parameter

Forming speed: 0~15M/Min

Product speed: 8~10M/min

Roller material: GCR12 bearing steel

Forming stations: 15 stations + 4 fold ed machine

Shaft diameter: 75mm

Forming structure: Guiding column,chrome-plated

Machine base frame: tube welding structure ,milling gauntry,punch

holes automatic

Transmission type: worm gear box

Motor power of main machine: 7.5KW*2sets

Bearing: HRB brand ,needle roll bearing, taper bearing

Bolt: 8.8 grades

Weight: about 8 tons

Cutting die : Cr12MoV

Profile: +/-0.5mm as drawing

Cutting Length Tolerance + / - 1 mm

Main Components

No. | Item Name | Quantity | Remark |

1 | Manual de-coiler | 1 set | 3 tons |

2 | Leveling machine | 1set | Wannan motor |

3 | Cutting device | 1 set | Engineer define |

4 | Punching device | 2 sets | Hydraulic Prepunching |

5 | Roll Forming Machine | 1 set | ¢75mm |

6 | Cutter mold | 6 units | Engineer define |

7 | Hydraulic station | 1 set | Engineer define |

7 | Product stand table | 5 sets | 2 m*5 |

8 | Folded machine | 1 set | ¢75mm *4 |

9 | Tool Box | 1 box | standard |

10 | Books | 1 book | Use manual, Wire diagram, |

11 | Spare parts | 1 set |

|

Roll Formed Pallet Rack Advantages:

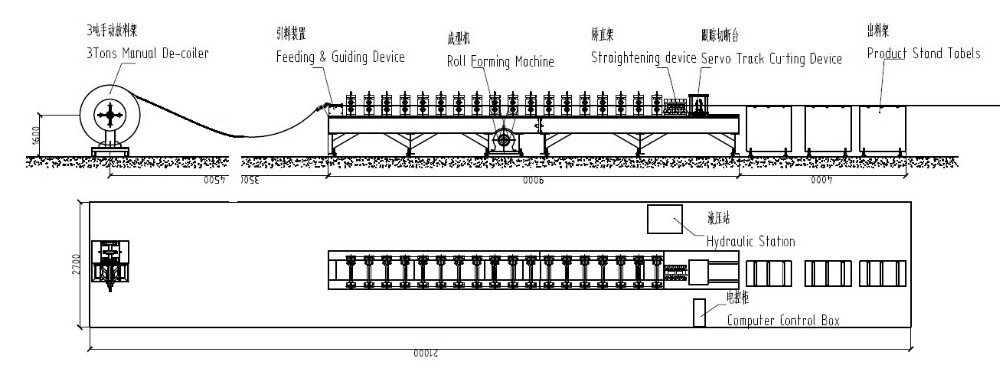

Working Flow of Roll Forming Machine

Manual de-coiler-->leveling machine -- roll forming machine

–Cutting device–>Product Stand Tables

Profile Drawing of Box beam

Photo