Hangzhou FAMOUS Steel Engineering Company |

|

Verified Suppliers

|

|

The tied arch bridge is composed of an arch rib on each side of the roadway, a tie beam associated with each arch rib which takes the thrust from the arches and a deck system supported by the tie beams. The deck system is most commonly composed of a concrete deck supported by longitudinal stringers in turn supported by transverse floor beams. Cable hangers connected between the arch ribs and the tie beams transfer the vertical loads from the tie beams to the arch ribs. Thus traffic passes between the arches at the lowest elevation of the arch ribs.

Usually the arches are parabolic and braced overhead for stability.

Thrust from the arch ribs is resisted by the tie beams.The deck system is isolated from the tie beams to insure that tensile stresses are not introduced into the deck when the tension in the tie beam increases. This is done by segmenting the deck using stress relief joints. Lateral loads are carried by a bracing system which works with the tie beams. It is common to construct bracing at both top and bottom flange levels of the floor beams.

The arch ribs principally resist thrust; but bending components can be rather large. If the arch ribs are loaded evenly, the bending is minimized. Bending in the arch rib is reduced for a given concentrated load if stiffness of the tie beam is increased. This is most easily envisioned by thinking of the tie beam as a beam on elastic foundations, i.e. the hangers and arch ribs act as the foundations. The stiffer the tie beam, the more evenly distributed is the force in the hangers.This leads to more even loading of the arch ribs. Since the deck has been structurally isolated from the tie beams, neither it nor the longitudinal stringers contribute stiffness to the tie beams.

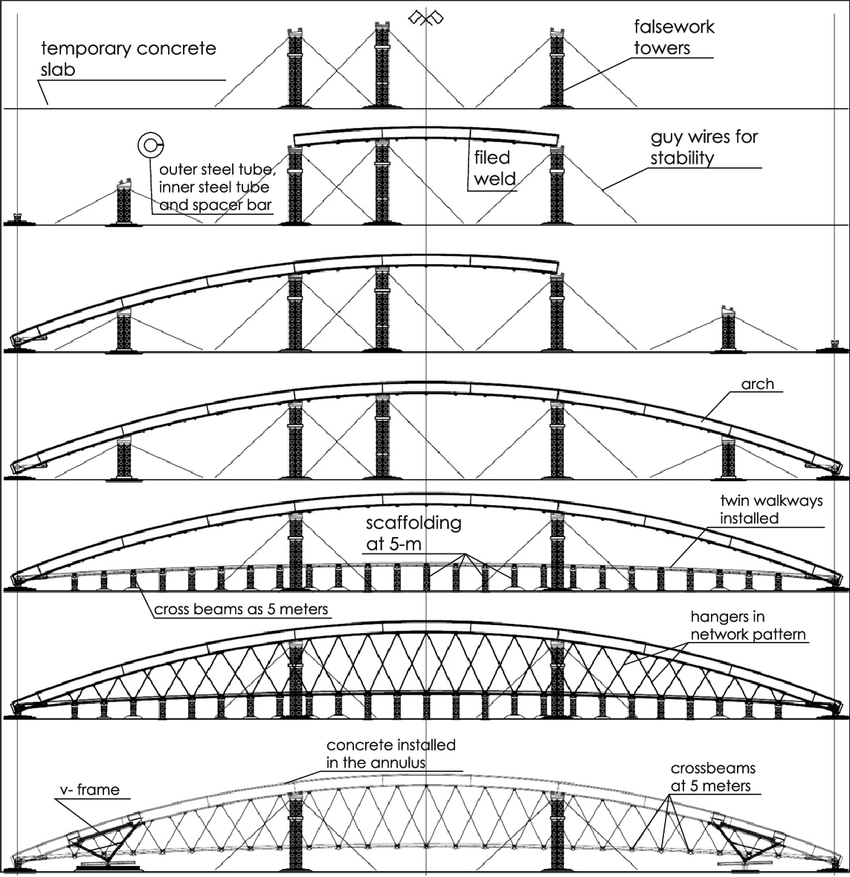

The structures are built from falsework. Spans range between 200 and 1000 feet for this type of bridge. They are used where single spans are required. If continuity from adjacent spans is available, tied arches are at a disadvantage compared to continuous trusses, cable stayed or even girder bridges.

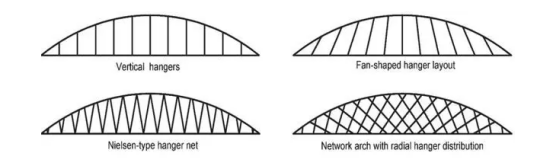

Different types of hanger arrangement are the followings:

In one hand Vertical and fan arrangement are better than network arrangement if fatigue is considered as the only parameter. But in other hand network arrangement is globally accepted if bending moment in arch and tie and the values of axial forces in hangers are considered.

Assembly of Tied arch bridges

Advantages of Tied arch bridges

* Variety of materials used for the construction of Tied Arch Bridges such as concrete, steel etc. so it’s very resistant to failure.

* Extremely strong, because the arch design allows the forces to the deck goes to arches via hangers which means no part of the bridge takes on the high amount of pressure. The half-circle design prevents any changes in the bride due to bending.

* They are very resistant so that the force due to moving transports the loads pass to the arches and equally distributed to both ends and that makes the force pressing action less in the middle on the bridge. This had made the bridge stronger than other traditional bridges.

They became stronger, this is because since the arch bridges are built to compress, they actually become stronger with more visit on them.

About Us

We always use high-quality structure steel in certified grades for bridge fabrication. Prefabrication of steelwork in our highly controlled factory conditions leads to high quality work at minimum cost. The excellent quality control is achieved through a thorough testing regime at the steel mills and during the fabrication processes of cutting and drilling, assembly, welding, and protective treatment. The quality assurance that is attained should give confidence to all clients and engineers who specify steel for their bridge project.

We will use Corten Steel for most type of bridges. Corten steel is

a high strength low alloy steel that in suitable environments forms

an adherent protective rust ‘patina’, to inhibit further corrosion.

The corrosion rate is so low that bridges fabricated from unpainted

weathering steel can achieve a 120 year design life with only

nominal maintenance.

Why Us

1.Highest national qualification–Grade I Professional Engineering

Contractor for Steel Structure

2. Able to undertake all kinds of steel structure projects

3. Obtained EU certification, AWS Qualification

4. Experienced in overseas projects

5. 36000㎡ workshop, senior engineer team, highly trained workers to ensure on-time delivery.

If you are interested, welcome to contact us for a quote.