EVERCROSS BRIDGE TECHNOLOGY (SHANGHAI) CO.,LTD. |

|

Verified Suppliers

|

|

Description:

Steel Cable Suspension Bridge is a flexible suspension combination system composed of a main cable and a stiffened beam has the stress characteristics of both cable and beam.

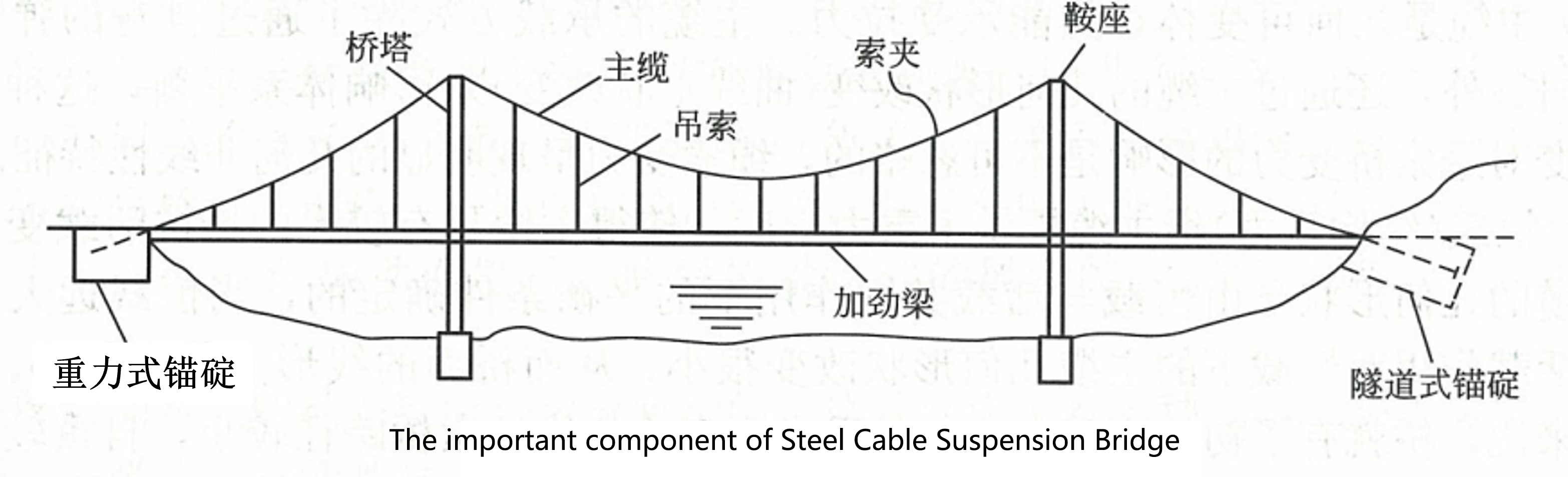

It consists of bridge tower, main cable, sling, stiffening beam, anchor, saddle and other main parts.

At present, most of the bridges with a span greater than 1000m are suspension bridge structures.

Load characteristics: the load is transmitted from the sling to the cable, and then the cable is transmitted to the anchor, to the pier and to the tower.

Under the external load, the main cable and stiffened beam bear the same force.

The main cable is the main load-bearing component, which deforms under load.

It directly affects the internal force and deformation of the bridge.

The main cable is the main load-bearing component in the structural system, which is mainly strained.

The bridge tower is the main load-bearing component of suspension bridge to resist vertical load.

The stiffening beam is a secondary structure of suspension bridge to ensure vehicle running and provide structural stiffness, and it mainly bears bending internal force.

The sling is a force transmission component that transmits the self-weight and external load of the stiffened beam to the main cable, and is the link connecting the stiffened beam and the main cable.

An anchor is a structure that anchors the main cable, which transmits the tension in the main cable to the foundation.

Main cable: The load is borne by the clamps and boom, and it is passed directly to the top of the tower.

The main cable is divided into two types: wire rope main cable and parallel wire bundle main cable.

1.Wire rope main cable: wire rope main cable is twisted into strands by wire, and then twisted into rope by strands. Generally, it adopts 7 strands and used for small span suspension bridges.

2.Parallel wire bundle main cable.

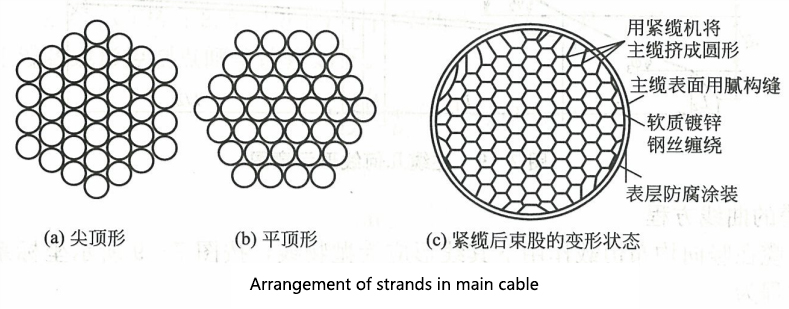

Prefabricated parallel steel wire strand method (PPWS method): the use of parallel steel wire to speed up the construction progress of the main cable, the section shape is divided into pointed and flat top shape.

Bridge tower:

1. Bridge to form

According to the mechanical properties, it can be divided into three structural forms: rigid tower, flexible tower and rocking column tower.

A rigid tower refers to a bridge tower with relatively small horizontal displacement at the top. The flexible tower. It refers to the bridge tower with relatively large horizontal displacement at the top. Rocking column tower, it is only used for suspension bridges with small span, and the lower end is hinged single-column structure.

2. Cross bridge form

The bridge tower of transverse bridge adopts three forms: truss type, rigid frame type and mixed type structure.

Main parameters involved:

The main parameters that affect the design of bridge tower are: material parameters, environmental parameters and structural size parameters.

Stiffening beam:

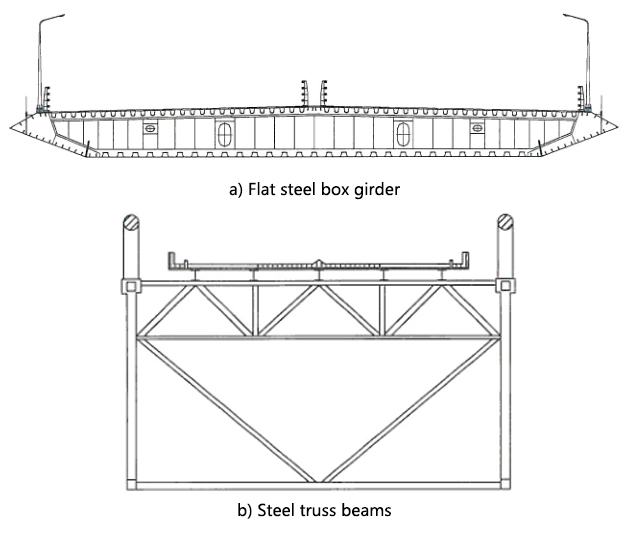

The types of stiffened beams mainly include steel truss beams, steel box beams, concrete beams, steel-mixed composite beams and other structural forms, as shown in the figure:

Sling:

(1) The material of the sling:

It can be made of steel wire rope, parallel steel wire bundle or steel strand.

(2) Connection mode with cable clamp

Straddle type, pin type

(3) Vertical sling and diagonal sling

Traditional slings are vertical, starting with the Severn Bridge in the United Kingdom.

Anchorage:

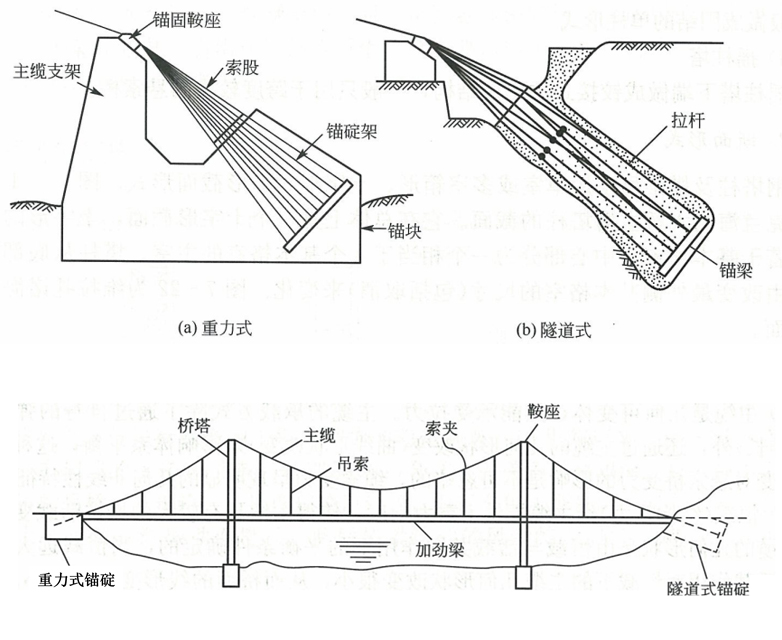

The anchorage of ground anchored suspension bridge is divided into two structural forms: gravity anchorage and tunnel anchorage, as shown in the figure: Gravity anchorage is composed of anchor body, bollard, anchor chamber and foundation. Tunnel anchorage is composed of anchor plug body, loose saddle support pier and anchor chamber.

Compared with gravity anchorage, tunnel anchorage has much less concrete consumption and more significant economic performance. In terms of applicability only, gravity anchorage is suitable for almost all occasions. When the comprehensive geological condition of the anchor site is good, the terrain is conducive to the overall layout of the whole bridge, and the construction conditions can meet the tunnel excavation and slag discharge. From the economic point of view, the possibility of building tunnel anchors should be considered first. Only when the construction conditions are considered comprehensively and the comprehensive technical and economic comparison shows that tunnel anchors are obviously unsuitable, the gravity anchors are chosen to be built.

Saddle:

The saddle sits between the main cable and the top of the tower. The saddle is an important member that supports the main cable and gives the main cable a turning angle here. Through it, the pull force in the main cable can be evenly transmitted to the top of the tower and the anchor in the form of vertical force and unbalanced horizontal force.

The saddle is divided into the main rope saddle at the top of the tower and the loose rope saddle at the anchor.

The structural system of suspension bridge is mainly to determine the support constraint system of stiffened beams. Generally, the stiffened beams of three-span suspension bridge are mostly non-continuous, that is, three-span simply supported system. The three-span suspension bridge with simple support system is reasonable in terms of structural force, but the mid-span deflection, beam end expansion and beam end Angle are large, which will affect the driving comfort. For Bridges with higher requirements for deck deformation (including beam end Angle deformation, expansion and mid-span deflection) and driving comfort, three-span continuous suspension Bridges are adopted.

Classification of steel cable suspension bridges:

1.According to the number of suspension span are divided into: single-span suspension bridge, three-span suspension bridge, four-span suspension bridge, five-span suspension bridge.

2.According to the main cable anchoring form are divided into: ground anchor and self-anchoring.

Ground anchorage: The tension of the main cable is transferred to the foundation by the gravity anchorage or tunnel anchorage at the end of the bridge.

Self-anchoring: The main cable tension is transmitted directly to its stiffening beam.

Steel cable suspension bridge construction method:

The construction process of suspension bridge is: anchor foundation construction, anchor construction, bridge tower foundation construction, bridge tower construction, main cable construction, stiffened beam construction, bridge deck construction, etc.

The width-span ratio of a suspension bridge refers to the ratio between the width of the bridge floor system (or the cable center distance) and the span of the mid-span, which is generally 1/60 to 1/40. The wide span ratio is an important index of the lateral stiffness of suspension Bridges, which directly affects the wind resistance performance of suspension Bridges. The effect of beam width-span ratio on torsional performance is obvious. The larger the width-span ratio is, the smaller the torsion Angle of the stiffened beam is. According to statistics, the width-span ratio of more than 30 suspension Bridges at home and abroad is greater than 1/60 except for the Humber Bridge in the United Kingdom, which is 1/64.

Protection design of Steel Cable Suspension Bridge

(1) Concrete structure

Concrete structure protection design mainly adopts the following measures:

(2) Steel structure

The protection design of suspension bridge steel structure mainly adopts the following measures:

Advantages of Steel cable suspension bridge: steel cable suspension bridge has become more and more the preferred type of bridge with large span (over 1000m) because of its large span capacity, good seismic performance and light appearance.

It's important to note that the design and construction of steel cable suspension bridges require careful engineering analysis, considering factors such as loadings, material properties, and site conditions. Additionally, ongoing maintenance and inspection are crucial to ensure the long-term safety and functionality of these structures.

Evercross Steel Bridges Overview :

| EVERCROSS STEEL BRIDGE SPECIFICATION | |

| EVERCROSS STEEL BRIDGE | Bailey bridge (Compact-200, Compact-100, LSB, PB100, China-321,

BSB) Modular bridge (GWD, Delta, 450-type, etc.), Truss Bridge, Warren bridge, Arch bridge, Plate bridge, Beam bridge, Box girder bridge, Suspension bridge, Cable-stayed bridge, Floating bridge, etc. |

| DESIGN SPANS | 10M TO 300M Single span |

| CARRIAGE WAY | SINGLE LANE, DOUBLE LANES, MULTILANE, WALKWAY, ETC |

| LOADING CAPACITY | AASHTO HL93.HS15-44, HS20-44, HS25-44, BS5400 HA+20HB, HA+30HB, AS5100 Truck-T44, IRC 70R Class A/B, NATO STANAG MLC80/ MLC110. Truck-60T, Trailer-80/100Ton, etc. |

| STEEL GRADE | EN10025 S355JR S355J0/EN10219 S460J0/ EN10113 S460N/BS4360 Grade

55C AS/ NZS3678/ 3679/ 1163/ Grade 350, ASTM A572/A572M GR50/GR65 GB1591 GB355B/C/D/460C, etc. |

| CERTIFICATES | ISO9001, ISO14001, ISO45001, EN1090, CIDB, COC, PVOC, SONCAP, etc. |

| WELDING | AWS D1.1/AWS D1.5 AS/NZS 1554 or equivalent |

| BOLTS | ISO898, AS/NZS1252, BS3692 or equivalent |

| GALVANIZATION CODE | ISO1461 AS/NZS 4680 ASTM-A123, BS1706 or equivalent |