Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

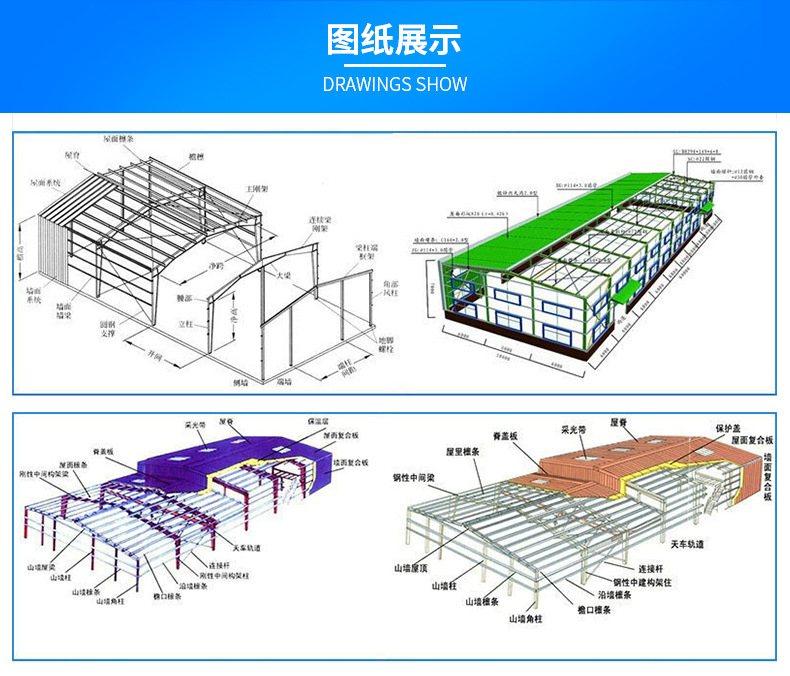

Light Gauge Steel Framing Prefabricated Factory / Shed Steel Structure Workshop

Light Gauge Steel Framing Prefabricated Factory / Shed Steel Structure Workshop This is a Prefabricated Workshop Buildings that we design, fabricated the steel structure and installation. Welded H-section steel columns and beams are connected by high strength bolts to be the main frame structure of the buildings. Steel structure is made from organized combination of structural steel members designed to carry loads and provide adequate rigidity. The members of the steel structures are made of steel and are joined by welding, riveting or bolting. These structures are reliable and require less material than other types of structures due to the high strength of steel which are distinguished by the diversity of their shapes and their architectural expressiveness.

Although the density of steel is larger than that of other building materials, its strength is very high. Under the same force, the steel structure has a small weight and can be made into a structure with a large span.

| Steel Frame | H section steel | Q235/Q355 steel plate thickness: 8-30mm |

| Welding | Automatic submerged arc welding | |

| Rust removal | Sand blasting | |

| Surface finish | Alkyd paint or galvanized | |

| Intensive bolt | M20,Grade 10.9 | |

| Supporting System | Angle brace | L50x4,Steel Q235, processed and painted |

| Horizontal brace | Φ20, Steel Q235, processed and painted | |

| Column brance | Φ20, Steel Q235, processed and painted | |

| Tie rod | Φ89*3, Steel Q235, processed and painted | |

| Ordinary bolt | M12 Galvanized bolt | |

| Roof | Purlin | C160*60*2.5,Steel Q235, galvanized and painted |

| Roof panel | Sandwich panel or corrugated steel sheet | |

| Sky light | 6mm thick PVC | |

| Accessories | Glass cement, self-tapping screws, etc. | |

| Edge cover | 0.4mm steel sheet profile trimming | |

| Gutter | 0.4mm thick sheet steel profile or galvanized sheet | |

| Down pie | Φ110PVC | |

| Walls | Purlin | C160*60*2.5,Steel Q235, painted |

| Wall | Sandwich panel or corrugated steel plate | |

| Accessories | Glass cement, self-tapping screws, etc. | |

| Edge cover | 0.4mm steel sheet profile trimming | |

| Ventilation | Ventilation ball | |

| Doors & windows | Rolling door/sliding door PVC/alu/steel/window |

1. Good performance of heat-insulation, waterproof performance and

fireproof performance.

2.Light weight, convenient for shipment and transportation

3. Various designs available, and welcome to customized design.

4. Manufacture with strict quality rules.

5. Easy to assemble and disassemble with simple and common

tools,and you can get installation guide for free.

6. Main materails: Section Steel/sandwich panel/ corrugated steel

sheet

7. Safety and stable,could stand firmly over 50 years

8.Nice appearance, easy to maintenance.

1. Structural steel fabrication, painting , galvanizing , pre-assembly

2. Designing, fabrication and installation for Prefabricated steel structure building.

3. Deepen or design the fabrication drawing or shop drawing based on your architectural drawing and construction drawing

4. Engineering consulting service

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40’HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

Q1:How to guarantee the quality of the products?

We have our own QC team to control the products quality for all our clients'orders before loading.

Q2:How long does it take to install the steel structure workshop?

Depends on the building size, usually 1 month.

Q3:Is the steel structure workshop insulated?

Yes, you can choose insulated sandwich panel wall and roof, with different thickness building gain insulation level.

Q4:It is the building rain proof?

Yes, roof sandwich panel or single steel sheet, be well joint togehter with full set of drainge system.

Q5:Does it come with all the designed components and parts?

Yes,Ruly provide turn-key project, all the components with door, windows, aluminum and steel profiles be shipped together. And be signed for your installation.

Q6:If Ruly help on related equipment source?

Yes, if you want to shipped your equipment like stainless steel furniture, air handing units, fans etc. we can source for you and shipped together to save freight cost, and help control the quality.

Q7:How we do business?

Take care of your products and serve your needs.