Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

Prefab Metal Structure Warehouse Prefabricated Steel Structure Warehouse Construction Rigid Structure Large Space

Features And Advantages/Disadvantages Of Galvanization&Painting :

Steel structural components are typically treated with either galvanization or painting to provide protection and aesthetic appeal. Galvanization involves immersing the steel parts in molten zinc to form a zinc coating. Galvanization offers excellent corrosion resistance, effectively preventing oxidation and corrosion. Additionally, the galvanized surface is hard and abrasion-resistant, capable of withstanding scratches and wear.

However, galvanization also has some drawbacks. Firstly, the galvanization process is relatively complex and requires specialized equipment and expertise, increasing manufacturing costs. Secondly, the galvanized surface may exhibit uneven color or texture, affecting the appearance. Furthermore, the galvanized layer may corrode over prolonged use or under severe abrasion.

In comparison, painting involves applying paint coatings onto the surface of steel structural components. Painting offers a wide range of color choices and finishes, allowing for more personalized designs. Additionally, painting provides additional corrosion protection, preventing direct contact between the steel parts and the external environment.

However, painting also has some disadvantages. Firstly, the durability of paint coatings is generally inferior to galvanization, requiring regular maintenance and repainting to maintain appearance and protection. Secondly, the painting process is more complex, requiring time and labor-intensive efforts. Furthermore, painting costs are relatively higher and may increase the overall project expenses.

In conclusion, both galvanization and painting have their own advantages and disadvantages. Galvanization offers excellent corrosion resistance and abrasion resistance but comes with higher manufacturing costs. Painting provides more design options and corrosion protection but requires regular maintenance and higher manufacturing costs. When selecting a surface treatment method, it is important to consider these factors in a comprehensive manner based on specific requirements and budget constraints.

Structure details:

Our company and factory:

Our steel structure factory is a company with excellent capabilities and extensive experience. Our factory covers an area of 35,000 square meters and is equipped with modern facilities and two mature and professional production lines. We provide high-quality steel structure products and solutions to our customers with efficient production capacity and excellent quality management.

Firstly, our factory has a strong production capacity. We can produce 1,500 tons of steel structure products per month, ensuring timely delivery to meet customer demands. By optimizing production processes and adopting advanced production technologies, we have improved production efficiency and product quality.

Secondly, we prioritize quality management and product certifications. Our factory has obtained several international certifications, including ISO 9001 Quality Management Certification, ISO 14001 Environmental Management Certification, and OHSAS 18001 Occupational Health and Safety Management Certification. These certifications demonstrate our strict requirements for quality management and environmental protection, allowing customers to confidently choose our products.

Our factory also has the capability to undertake complex steel structure projects. We have contracted numerous challenging projects in the past, including large industrial buildings, commercial structures, and bridges. With an experienced engineering team and professional designers, we can provide comprehensive engineering solutions to meet customer requirements for design, manufacturing, and installation.

In addition to our own capabilities, we have established long-term cooperative relationships with customers and gained their trust and reputation. We are committed to closely collaborating with customers, understanding their needs, and providing customized solutions based on their specific requirements. Our goal is to create value for customers through high-quality products and excellent services, establishing long-lasting partnerships.

In summary, our steel structure factory has a strong production capacity, excellent quality management, extensive engineering experience, and good cooperative relationships with customers. We will continue to innovate and improve, providing customers with higher-quality steel structure products and services, and becoming a reliable partner you can trust.

Installation:

Method 1: We provide shop drawing before installation.

Method 2: If you still don't know how to install, We will teach you the installation in our factory. when necessary , we will assemble a sample steel structure building for you.

Quality control:

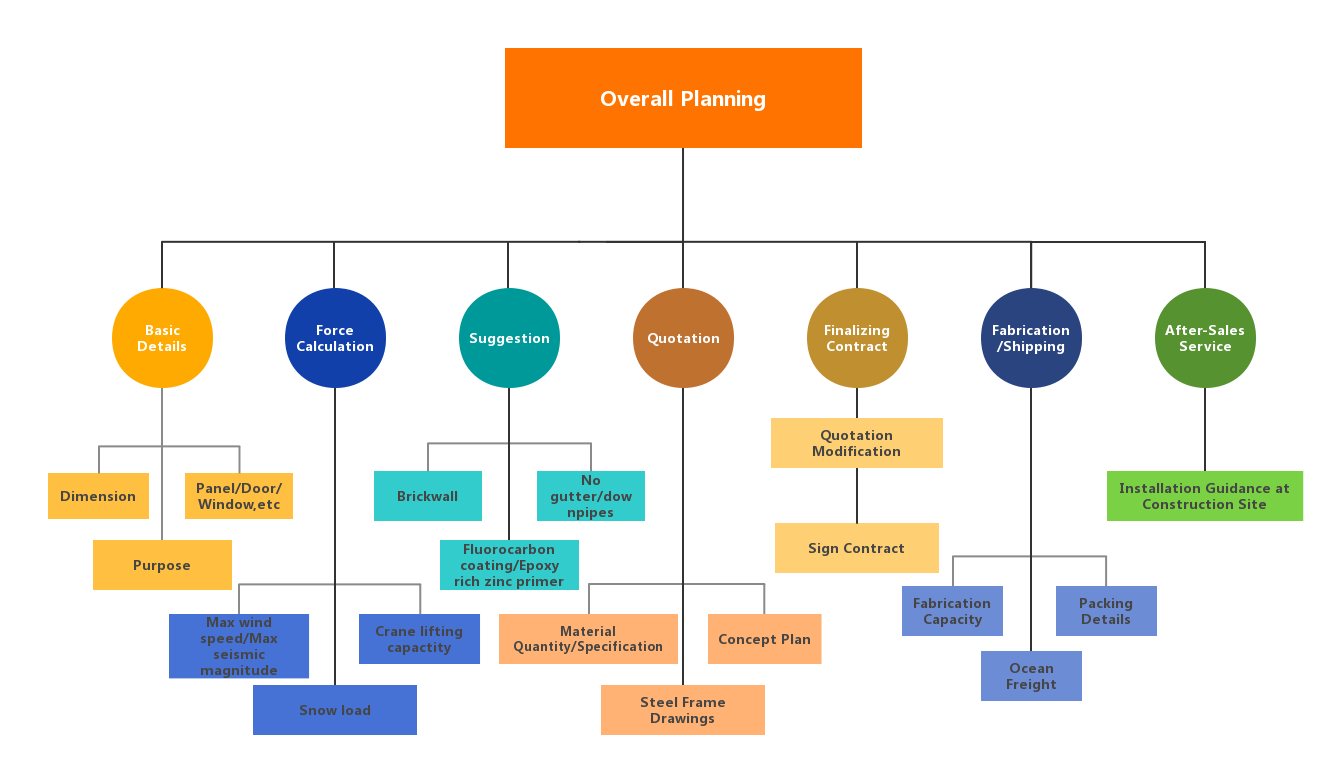

Overall plan:

Packing and loading:

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.

Why us:

1. Professional design team, we could design the drawing as your requirement or calculate the steel quantity based on your drawing.

2. Skilled fabrication team and advanced equipment. We make the independent production schedule to each project.

3. One-stop service: We have completed lots such kinds of projects, we could provide the integrated proposal for your project.

4. Professional QC team will guarantee that we will provide the production and service as your request.

5. After sales service: If it has any questions that need us to do in your process of using, such as the maintain of outside insulation and steel components, just tell us , we will try to provide the service as well as we can.