JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

S32750 (2507) is a duplex stainless steel that combines many excellent features of ferritic and austenitic steels. Due to its high chromium and molybdenum content, it embodies excellent resistance to pitting corrosion, crevice corrosion and uniform corrosion. The two-phase microstructure ensures that the steel has high resistance to stress corrosion cracking and high mechanical strength. Besides, it features strong resistance to chloride pitting, high thermal conductivity and low coefficient of thermal expansion.

In comparison with S32205 duplex steel, S32750 features higher strength and corrosion resistance. Compared to 904L, it is more resistant to corrosion caused by dilute sulfuric acid mixed with chloride ions. In contrast with austenitic stainless steel, it features higher yield strength and lower ductility. S32750 super duplex steel also features high impact strength, not suitable for use under temperatures above 570 °F or 300 °C, in that long exposure to such environment will lead to reduced toughness.

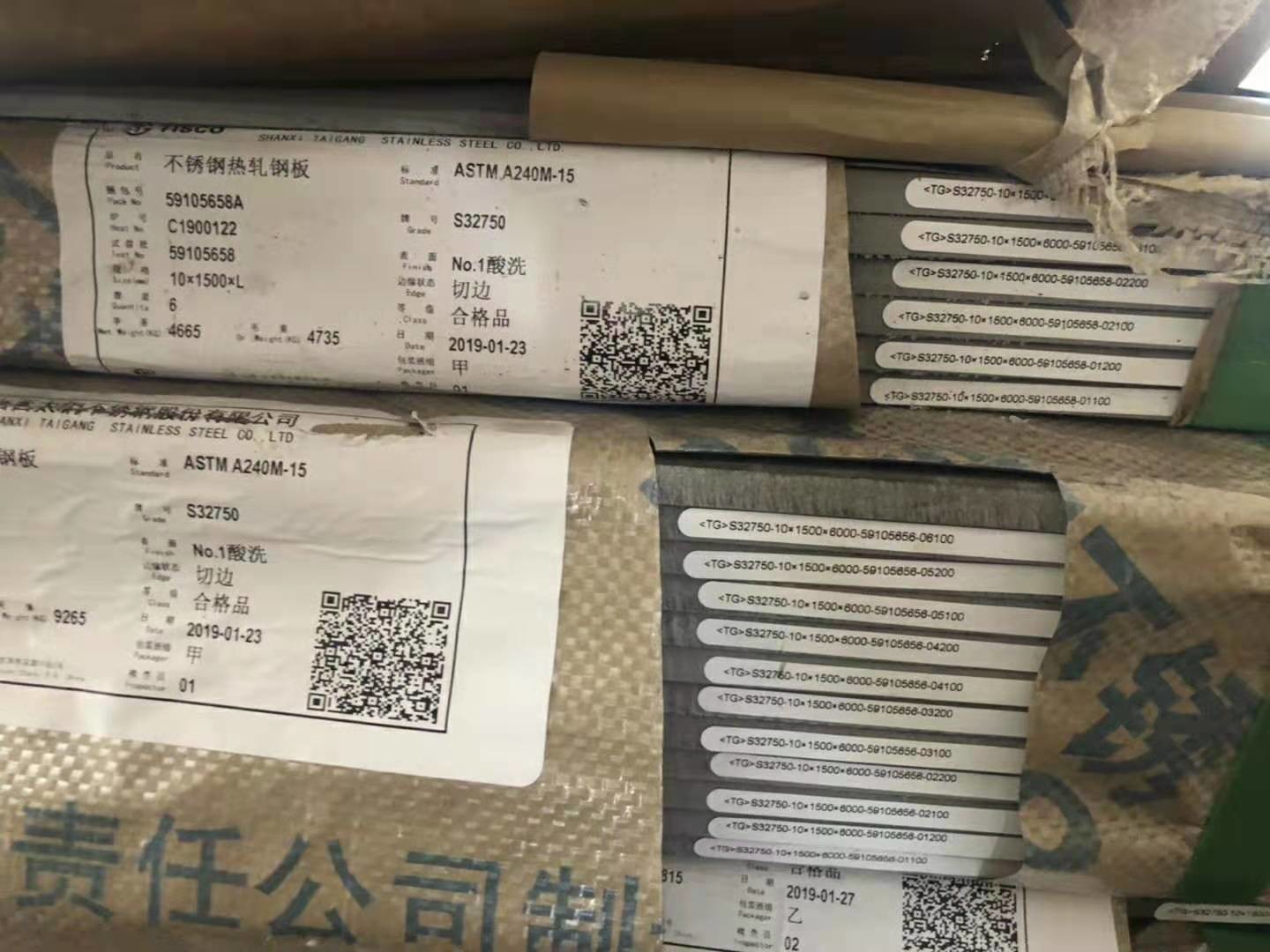

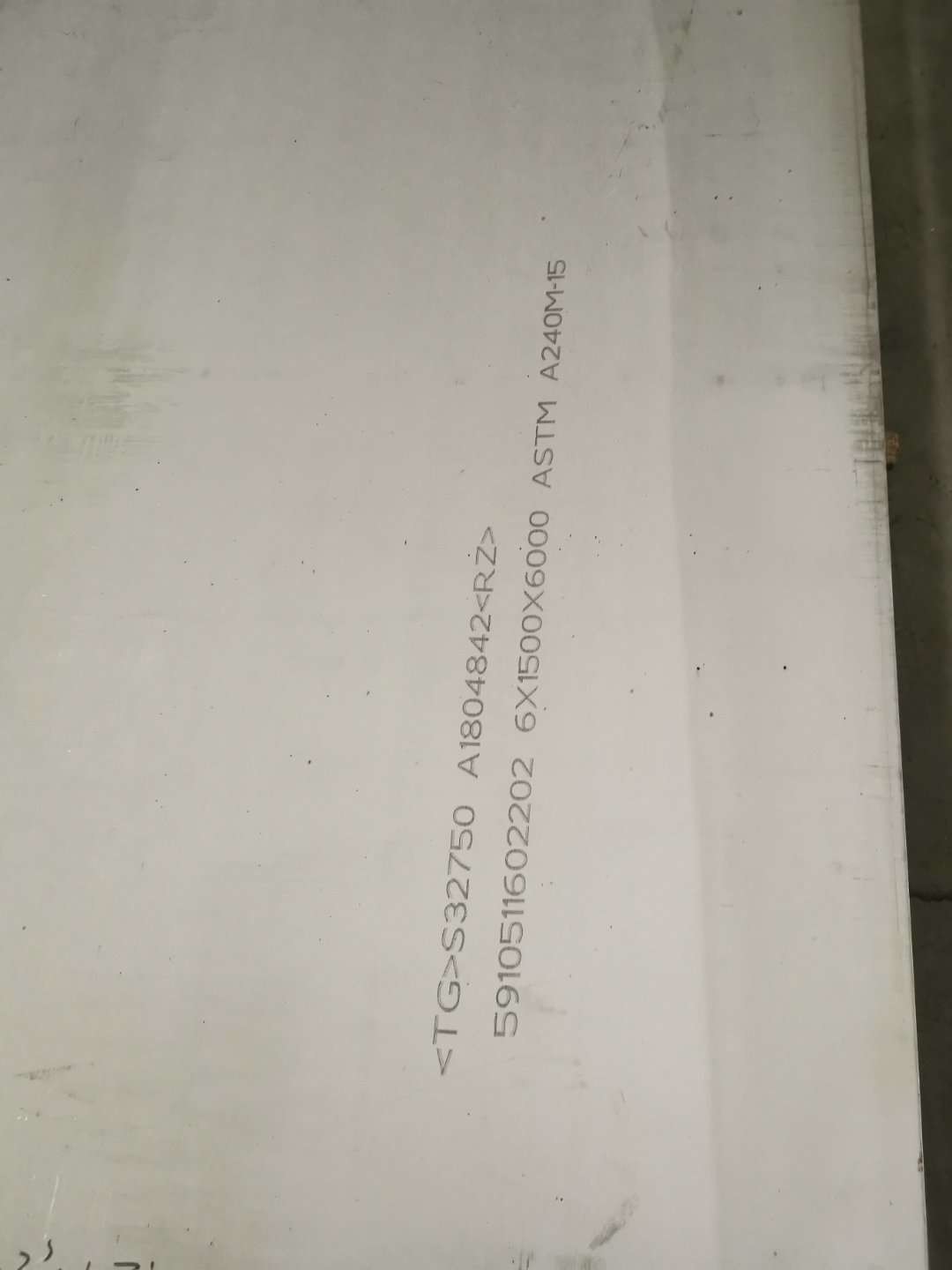

Specifications for Super Duplex 2507 / UNS S32750 Sheets & Plates. If any specification is not mentioned here, please use the contact button for quick quote.

| Specifications | ASTM A240 / ASME SA240 |

| Thickness | 4mm – 100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sand |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Grade | S32750 |

|---|---|

| C | 0.030 max |

| Mn | 1.20 max |

| Si | 0.80 max |

| P | 0.035 max |

| S | 0.020 max |

| Cr | 24.00 – 26.00 |

| Mo | 3.00 – 5.00 |

| Ni | 6.00 – 8.00 |

| N | 0.24 – 0.32 |

| Fe | 58.095 min |

| Grade | S32750 |

|---|---|

| Density (g/cm 3) | 7.8 |

| Density (lb/in 3) | 0.281 |

| Melting Point (°C) | 1350 |

| Melting Point (°F) | 2460 |

| Grade | Super Duplex S32750 |

| UNS No | S32750 |

| WERKSTOFF NR. | 1.4410 |

S32750 needs to be solution annealed and quenched after hot forming or cold forming. When it is done with solution annealing, the temperature should not be lower than 1925 °F, and air or water quenching should be carried out immediately. In order to secure the desired corrosion resistance, the heat treated steel needs to be subjected to pickling and rinsing.

S32750 features good weldability. Many common stainless steel forming methods are also suitable for S32750. It can be welded by a series of methods such as SMAW, GTAW, PAW, FCW, or SAW. When soldering S32750, it is advisable to use 2507/P100 metal, which will form a suitable two-phase structure.

Grade 2507, Type 2507, Inox 2507, SAF 2507, Grade S32750, Type S32750, Inox S32750, 1.4410, UNS S32750, NAS 74N, F53, Acero 2507.

If you want to buy S32750 stainless steel products, please contact the RIGHT supplier - Mittel to get the latest price.