JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

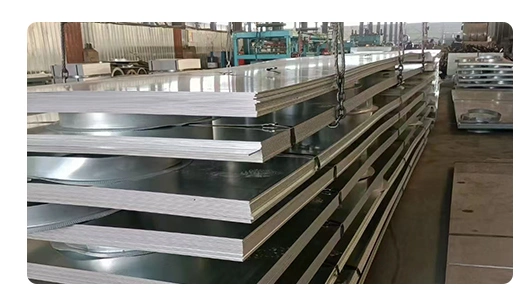

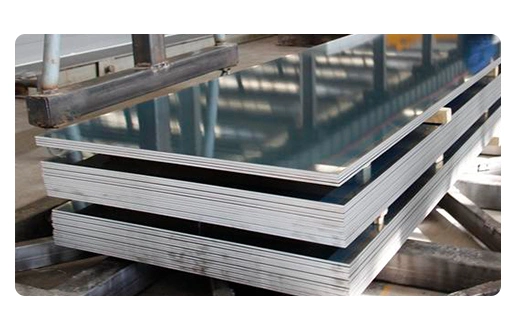

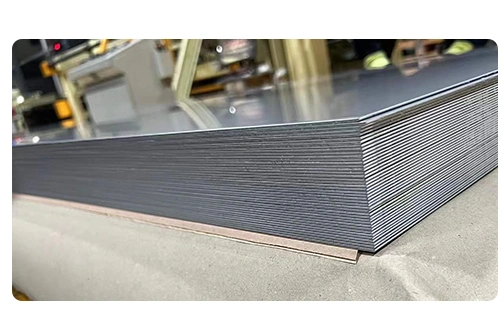

Cold Rolled Steel Sheet Quality Standard SAE 1020 20# Thickness 2.5 mm 1250*2500mm

American standard SAE1020 carbon structure cold rolled steel plate

Mainly used in: automotive steel, construction steel, cold/hot

rolled steel, coil, coated, high-strength steel, color-coated coil

and other steel products.

SAE1020 carbon structural steel plate has low mechanical strength,

good plasticity and toughness, easy to deform in cold state, easy

to cut and process, good welding performance, and can be carburized

and cyanided to improve surface hardness. It is mainly used to

manufacture low-strength welded parts, cold stamping parts,

forgings and carburized parts such as bolts, washers, partitions,

shells, etc.

The following are its chemical properties (smelting analysis):

Carbon C: 0.16-0.22

Silicon Si: 0.15~0.35

Manganese Mn: 0.60-0.90

Sulfur S: ≤0.050

Phosphorus P: ≤0.040

Chromium Cr: ≤0.20

Nickel Ni: ≤0.25

Copper Cu: ≤0.25

Cold rolled steel plate is the abbreviation for ordinary carbon structural steel cold rolled plate, also known as cold rolled plate. Cold rolled steel plates are hot-rolled steel strips of ordinary carbon structural steel, which are further cold rolled to produce steel plates with a thickness of less than 4mm. Due to the fact that rolling at room temperature does not produce oxide scale, the cold plate has good surface quality and high dimensional accuracy. In addition, annealing treatment results in better mechanical and technological properties than hot-rolled thin steel plates. In many fields, especially in the field of home appliance manufacturing, it has gradually been used to replace hot-rolled thin steel plates.

| Usually available specification range | |||||

| Variety | thickness | width | length(or coil inner diameter) | ||

| steel plate | trimming | 0.30~3.5 | 900~1830 | 1000~6000 | |

| No trimming | 900~1850 | ||||

| steel belt | trimming | 0.30~3.5 | 900~1830 | 610(the inside diameter of) | |

| No trimming | 900~1850 | ||||

| Slitting steel strip | 0.30~3.5 | 120~<900 | |||

| Technical Standards for cold rolled steel coil | |||||

| grade | Zhengde enterprise standard | Comparable to foreign standards | illustrate | ||

| Standard | Grade | Standard | Grade | ||

| general use | Q/BQB403 Q/BQB402 | St12 SPCC | DIN1623JISG3141 | St12 SPCC | For general forming processing such as refrigerators and other home appliance shells, oil barrels, and steel furniture. |

| stamping grade | Q/BQB403 Q/BQB402 | St13 SPCD | DIN1623JISG3141 | St13 SPCD | Steel for stamping and forming processes such as automobiles, home appliances, and construction. |

| Deep drawing | Q/BQB403 Q/BQB402 | St14, (F, HF, ZF)SPCE (F, HF, ZF) | DIN1623JISG3141 | St13 SPCE | Automobile headlights, fuel tanks, car doors, windows and other steels for deep drawing and forming. |

| Steel for extra deep drawing | Q/BQB403 | St15 St14T | Car headlights, complex underbody panels, oil pans. | ||

| hard steel | Q/BQB402 | SPCC4D SPCC8D SPCC1D | JISG3141 | 1/4 hard1/8hard | Steel for bicycle rims and steel for stationery. |

| structural steel | Q/BQB410 BZJ410 | St37-2G St44-3G St52-3G | DIN1623 | St37-2G St44-3G St52-3G | Buildings, car bodies, brackets. |

| Atmospheric resistant steel | BZJ441 | B440NQ B450NQ B460NQ B500NQ | Automobile, train car outer panels, container panels, doors and windows, cold-formed steel and other components. | ||

| steel for car wheels | BZJ412 | B320LW B360LW | Steel for automotive wheel rims. | ||