JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

NIckel Inconel X750 Alloy Steel Round Bar UNS N07750 Precipitation-Hardenable Bar

Product Name | inconel x750 738lc 725 round bar | ||

Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc | ||

Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS

S32760,2304,LDX2101.LDX2404,LDX4404,904L Others: 153Ma,254SMo,253Ma,654SMo,F15,Invar36,1J22,N4,N6 etc Alloy : Alloy 20/28/31; Hastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N; Haynes: Haynes 230/556/188; Inconel: Inconel 100/600/601/602CA/617/625/713/718738/X-750,Carpenter 20; Incoloy: Incoloy 800/800H/800HT/825/925/926; GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 Monel: Monel 400/K500 Nitronic: Nitronic 40/50/60; Nimonic: Nimonic 75/80A/90 ; | |||

Length | <6000mm | Diameter | 8-200mm |

Section shape | Round/ Square | Certification | ISO9001, SGS, |

MOQ | 50KG | Delivery | 7-15 days |

Inconel® X-750, also known as Nickel Alloy X-750, is popular and cost-effective precipitation-hardenable nickel-chromium alloy. Inconel X-750s wide spread use is due to its numerous benefits which include:

Hardness: HRC 32 – 42 in the solution and precipitation heat treated

condition (depending on heat treatment).

Density: 0.299 lbs per cubic inch.

Modulus of Elasticity: 31 MSI in STA condition.

Coefficient of Expansion: 7.8 x10-6 in/in/F, RT-800F. 8.4 x10-6 in/in/F, RT-1200F.

Inco X750 has a Machinability rating of 16. Like other nickel-base superalloys, the machinability of Inconel X-750 is inferior to that of most steels including stainless steels. Nevertheless, with proper selection of tool materials, speeds, feeds, and coolants, it can be machined in either the annealed or age-hardened condition. Due to the strength and hardness of Inco X750, one should perform any rough machining before precipitation hardening.

Inconel X750 has fair welding ability, particularly in conjunction with gas-tungsten-arc (GTA), plasma-arc, and electron-beam welding. Inconel 718 weld filler is the preferred choice to help resist strain age cracking. Welding is generally carried out on solution annealed material and appropriate post-weld heat treatment is employed to develop the desired properties. The precipitation hardened alloy is also weldable, but weld joints are susceptible to cracking and will be relatively soft and weak until heat treated. A full post-weld solution, anneal and precipitation heat treatment is most often applied to obtain optimum properties in weldments.

Forming for Inconel X-750 is fair to good in the solution annealed condition. Due to its rapid strain hardening rate, frequent in-process anneals are necessary when complex shapes are desired.

Inco X750 has good resistance to general corrosion and stress corrosion over a wide range of temperatures under both oxidizing and reducing conditions.

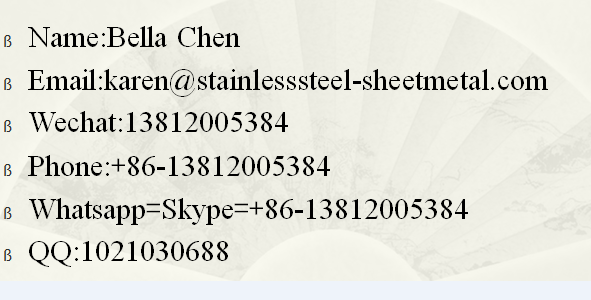

Contact me