TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

API ANSI 150LB 3 inch CF8 CF8M Stainless Steel 304 316 Globe Valve

Size: DN15-300mm

Pressure: Pressure: PN 10/16/25, ANSI150/300lb

Actuator: Manual

Type: Bolted Bonnet, OS&Y, straight/Y type/right angle

Standard: DIN, BS, API

Face to Face Dimension: DIN3202 or ANSI B16.10,

Flanged Dimension: DIN2501, ANSI B16.5

Industrial applications: Petroleum, Chemical, Paper Making,

Fertilizer, Coal Mining, water treatment and etc.

| PART | MATERIAL | STANDARD |

| Body | Cast iron, Ductile iron | ASTM A126 CLASS B |

| Seat Ring | Cast Bronze | ASTM B62 |

| Disc | Cast Bronze | ASTM B62 |

| Gasket | Brass | ASTM B16 |

| Bonnet | Cast iron | ASTM A126 CLASS B |

| Packing | Graphite | |

| Stem | Brass | ASTM B16 |

| Bolts | Steel | ASTM A307 B |

| Nuts | Steel | ASTM A307 B |

A Globe valves is a linear motion valve and are primarily designed to stop, start and regulate flow. The disk of a Globe valve can be totally removed from the flowpath or it can completely close the flowpath.

Conventional Globe valves may be used for isolation and throttling services. Although these valves exhibit slightly higher pressure drops than straight=through valves (e.g., gate, plug, ball, etc.), they may be used where the pressure drop through the valve is not a controlling factor.

Because the entire system pressure exerted on the disc is transferred to the valve stem, the practical size limit for these valves is NPS 12 (DN 300). Globe valves larger than NPS 12 (DN 300) are an exception rather than the rule. Larger valves would require that enormous forces be exerted on the stem to open or close the valve under pressure. Globe valves in sizes up to NPS 48 (DN 1200) have been manufactured and used.

Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to avert premature failure and to assure satisfactory service. Valves subjected to high-differential pressure-throttling service require specially designed valve trim.

Generally the maximum differential pressure across the valve disc should not exceed 20 percent of the maximum upstream pressure or 200 psi (1380 kPa), whichever is less. Valves with special trim may be designed for applications exceeding these differential pressure limits.

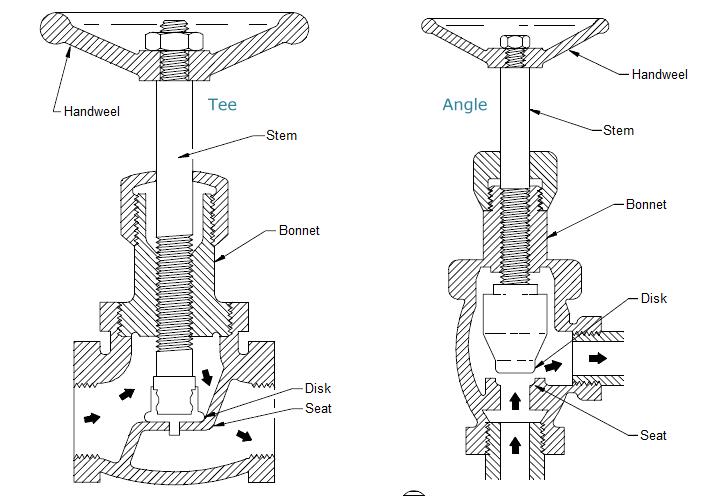

There are three primary body designs for Globe valves, namely..

Tee Pattern or Z-body

Angle Pattern

Wye Pattern or Y-body body

Disk.. The most common disk designs for Globe valves are.. ball disk, composition disk and the plug disk. Ball disk design is used primarily in low pressure and low temperature systems. It is capable of throttling flow, but in principle it is applied to stop and start flow.

Composition disk design uses a hard, non-metallic insert ring on the disk, which ensures a tighter closure.

Plug disk design provides better throttling than ball or composition designs. They are available in many different designs and they are all long and tapered.

Seat.. Globe valve seats are either integrated or screwed in to the valve body. Many Globe valves have backseats inside the Bonnet. Back seats provides a seal between the stem and Bonnet and prevents system pressure from building against the valve pakking, when the valve is fully open. Back seats are often applied in Globe valves.

Stem.. Globe valves uses two methods for connecting the disk and the stem.. the T-slot and the disk nut construction. In the T-slot design, the disk slides over the stem, while in the disk nut design, the disk is screwed into the stem.

The following are some of the typical applications of Globe valves..