Active Member

|

[China]

Address: Wen De Sixth Street,Sha Li Industrial park, Long Hu Road,Da Wang National High Tech Zone,Zhao Qing City,Guang Dong Province,China.

Contact name:Kate Liang

Guangdong ABLinox Sanitaryware Co., Ltd. |

|

New Arrival OEM Precision Investment Casting Automobile Parts Alloy Steel Steering Knuckle Raw Casting Surface

ABLinox wants to become a high-end customized expert in stainless steel industry.

ABLinox have been cooperated with some TOP 500 enterprises in the world.

ABLinox can be your one-stop-shop and has in-house machining capabilities as well as outside machining services available for specialized machining.

| Technology: | Lost Wax Casting,Investment Casting |

| Material: | Stainless Steel,304 316 2205 etc |

| Processing: | Casting+CNC machining+Surface treatment |

| Surface: | Polishing,Sand Blasting,Plating,Galvanized, Spray-Paint,etc |

| Origin: | Guangdong,China |

| Port: | Guangzhou |

| Samples: | 7-15 days |

| Delivery: | 30-35 days |

| Certificate: | ISO9001:2015 |

| Capacity: | 2500 tons/year |

| Size Capacity: | Thickness>6mm, Length<1000mm, Weight:0.1kg-100kg |

| Casting Tolerance: | GB CT4~CT6 |

| Surface Roughness: | Ra 0.4um-12.5um |

| Usage | Used in metallurgy, automobile,ship hardware ,engineering industry, etc. |

Applications

| Overflow valve parts | Gate valve parts |

| Plunger valve parts | Gate valve parts |

| Instrument valve parts | Ball valve parts |

| Control valve parts | Butterfly valve parts |

| Regulating valve parts | Trap valve parts |

| Slag discharge valve parts | Steam trap parts |

| Diaphragm valve parts | plug valve parts |

| Diverter valve parts | Stopcock parts |

| Breathing valve parts | Eye valve parts |

| Stop valve parts | Blind valve parts |

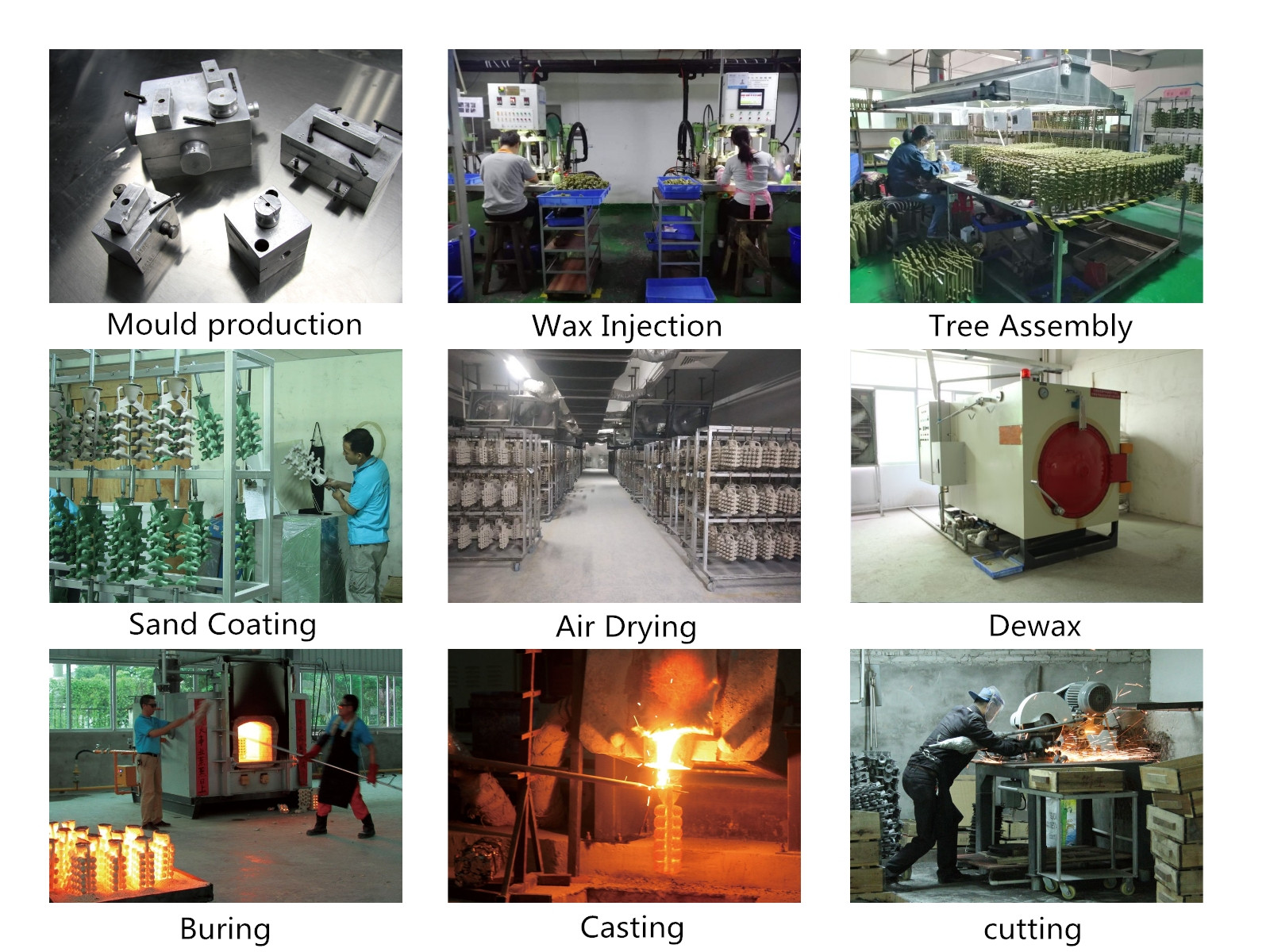

Production Process

Exceptionally smooth finish on castings

Casting accuracy of ± .005 per inch or better (capabilities

of ±.003 when required)

Production of large parts (35-40 pounds) and small or

miniature detailed parts (1/10 ounce or less)

Robotic molding system, adding strength in molds

High or low quantity production

Flexible, customizable design options

Equipments

We specialize in turning, drilling, tapping, and a variety of other machining capabilities to offer a complete product.

With these in-house turning capabilities, we also can quote your bar stock requirements, which complements

our investment casting line.

Our Service

1. In order to ensure the quality of the orders , our independent QC members to carry out strictly inspection at each stage

2. Incoming material inspection

3. Inspection of work-in -progres