JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

Nickel Alloy Inconel 600 Plate Thickness 0.5 - 30.0mm Alloy 600 Sheet According to ASTM SB168 B

| Products Name | Inconel 600 Nickel Alloy Sheet Plate |

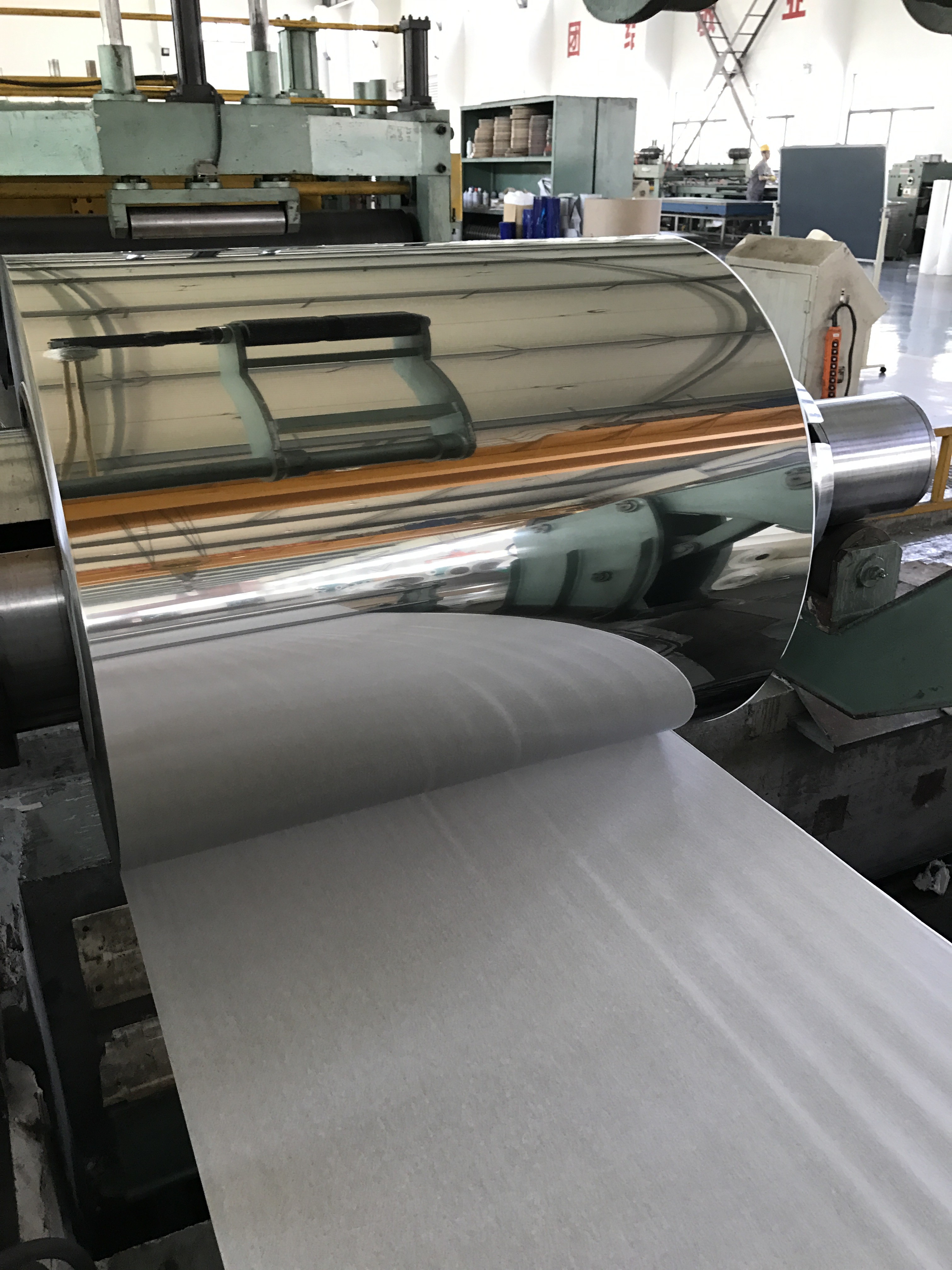

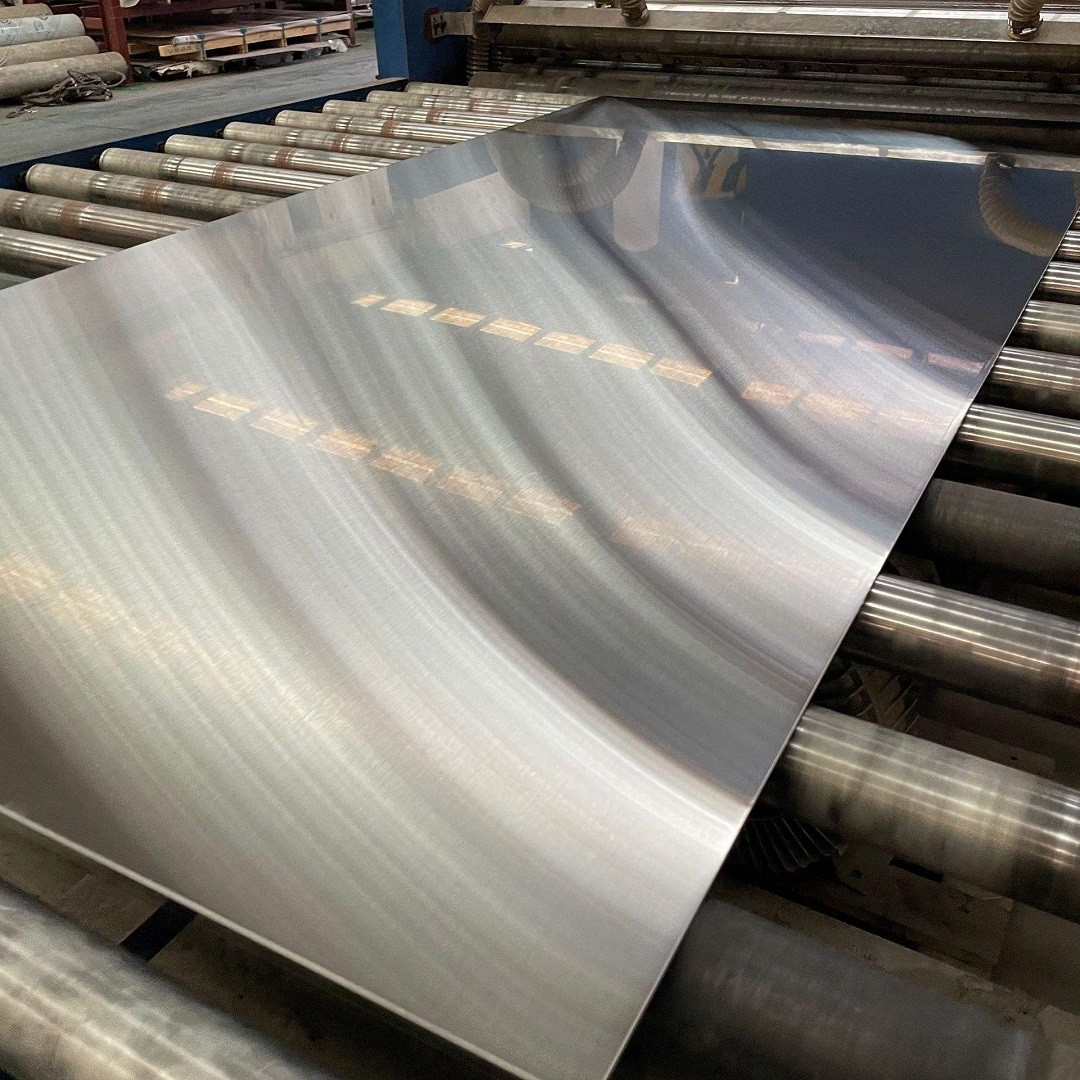

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Other Grade | Hastelloy C22 C4 X C276 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Alloy 600 is a nonmagnetic, nickel-based high temperature alloy

possessing an excellent combination of high strength, hot and cold

workability, and resistance to ordinary form of corrosion.

This alloy also displays good heat resistance and freedom from

aging or stress corrosion throughout the annealed to heavily cold

worked condition range.

Some typical applications are:

The high chromium content of alloy 600 raises its oxidation

resistance considerably above that of pure nickel, while its high

nickel content provides good corrosion resistance under reducing

conditions.

This alloy exhibits high levels of resistance to stress and salt

water, exhaust gases, and most organic acids and compounds.

Alloy 600 is not an age hardening alloy; cold working is the only available means of hardening. Softening by annealing begins at about 1600°F (871°C), and is reasonably complete after 10 to 15 minutes of heating at 1800°F (982°C). Above this temperature, grain growth may be objectionable, although very brief heating at 1900°F will cause complete softening without undue grain growth. Since the rate of cooling has no effect on the softening, the material may be water quenched or air cooled.

Hot Working/Forging

Low sulfur reducing furnace atmospheres should be used in forging.

Major hot working should be done between 2300/1850°F, while light

working may be continued as low as 1600°F. No hot working should be

attempted between 1600/1200°F due to lower ductility in that range.

Machinability

Alloy 600 is machinable in both the hot worked and annealed

conditions. Because considerable heat is generated in machining

this alloy, high-speed steel, cast nonferrous or cemented carbide

tools should be used. The tools should be kept sharp.

Lathe turning speeds with high-speed and nonferrous tools are 35/45

sfm (0.18/0.23 m/s); speeds with cemented carbide tools are 100/175

sfm (0.51/0.89 m/s). (This data should be used as a guide for

initial machine setup only. The figures used are averages. On

certain work, the nature of the part may require adjustment of

speeds and feeds.)

Sulfur-based oil should be used as a lubricant, but should be

completely removed before the machined part is exposed to elevated

temperatures, as in welding.

Cold Working

For higher properties, alloy 600 can be cold worked below 1200°F

(649°C).

Welding

Alloy 600 can be joined by the usual welding , brazing, and

soldering process.

Typical Mechanical Properties

Various forms and conditions

| Form and Condition | Tensile Strength | 0.2% Yield Strength | % Elongation in 2" | % Reduction of Area | Rockwell Hardness | ||

| Rod and Bar Cold-drawn Annealed As-drawn Hot rolled Annealed As-rolled Hot-finished Strip Annealed | 80-100 105-150 80-100 85-120 80-120 80-100 | 552-689 724-1034 552-689 586-827 586-827 552-689 | 25-50 80-125 30-50 35-90 35-90 30-45 | 172-345 552-862 207-345 241-621 241-621 207-310 | 55-35 30-10 55-35 50-30 50-30 55-35 | 70-60 60-30 70-60 65-50 65-50 ---- | 65-85B 90B-30C 65-85B 75-95B 75-95B 84B max. |

Average Room Temperature Tensile Data

| Form | Condition | Ultimate Tensile Strength, Ksi (MPa) | Yield Strength at 0.2% offset, Ksi (MPa) | Elongation in 2 in. (50.8mm) or 4D, percent |

| Sheet Plate Bar/Billet Sheet, Plate, Strip, Bar | Annealed Annealed Annealed Annealed | 98 (676) 95 (655) 95 (655) 80 (550)* | 42 (290) 41 (283) 41 (283) 35 (240)* | 40 45 45 30* |