JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

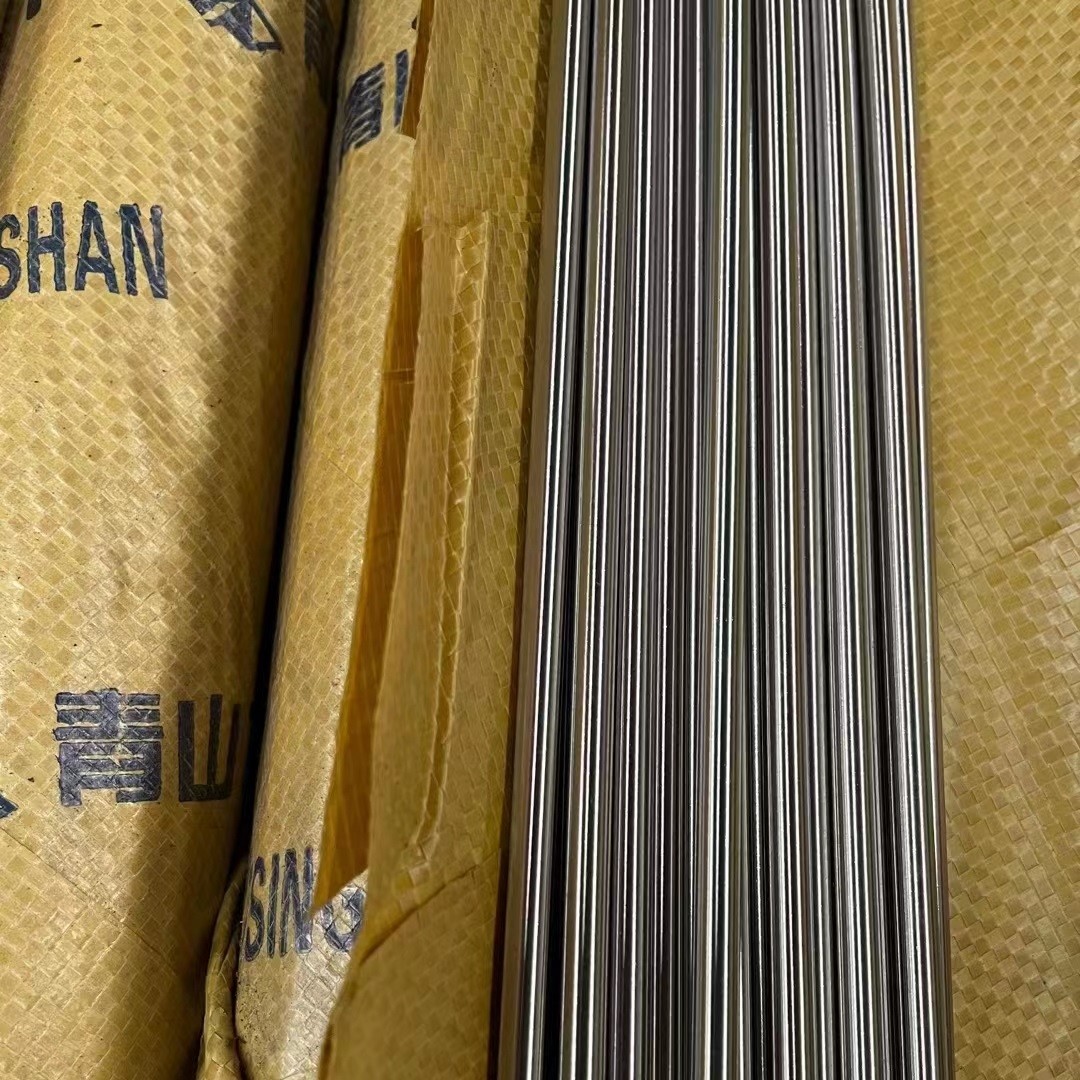

UNS N08904 / 904L Stainless Steel Bar Bright Polished Diameter 4 - 60mm Stainless Rod

| Products | Stainless Steel Bar |

| Grade | 201 303 304 304L 309S 310S 316L 316Ti 317L 321 347 410 420 430 431 17-4PH 2205 2507 904L C276.etc |

| Finishing | Bright / Black |

| Diameter | 3 - 300mm |

| Tolerance | H5 H6 H7 H8 H9 H10 H11 H12 H13 |

| Length | 6m or custom cutting as request |

| Service | Cutting. Polishing, heat treatment |

| MOQ | 200 Kgs |

| Deliver time | 10 - 15 Days based on the quantity |

| Packing | wooden box, or packing as request |

| Loading Port | Shanghai Port. Ningbo Port |

| Other Shape | Round, Square, Flatness, Hexagonal , Angle, Channel |

| Company Type | Factory |

Alloy 904L (UNS N08904) is a super austenitic stainless steel that is designed for moderate to high corrosion resistance in a wide range of process environments. The combination of high chromium and nickel content, coupled with additions of molybdenum and copper, assure good to excellent corrosion resistance. With its highly alloyed chemistry — 25% nickel and 4.5% molybdenum, 904L provides good chloride stress corrosion cracking resistance, pitting and general corrosion resistance superior to 316L and 317L molybdenum enhanced stainless steels. Alloy 904L was originally developed to withstand environments containing dilute sulfuric acid. It also offers good resistance to other inorganic acids such as hot phosphoric acid as well as most organic acids. Alloy 904L is easily welded and processed by standard shop fabrication practices.

Resistance to corrosion

RESISTANCE TO CORROSION

The high content of alloying elements in 904L gives the alloy exceptionally good resistance to uniform corrosion. 904L was originally developed to withstand environments containing dilute sulphuric acid, and is one of the few stainless steels that, at temperatures up to 95°F (35°C), provides full resistance in such environments within the entire concentration range of 0 to 100%. 904L also offers good resistance to a number of other inorganic acids, such as phosphoric acid and most organic acids. However, acids and acid solutions containing halide ions can be very aggressive, and the corrosion resistance of 317L,317LMNand904Lmaybeinsufficient. Fractional distillation of tall oil often needs better material than 316Lor even the more frequently used 317LMN. In these hot concentrated caustic solutions, the corrosion resistance is mainly determined by the nickel content of the material. With a nickel content of 25%, 904L has proven to be a good alternative to most conventional stainless steels. Conventionalstainlesssteelssuchas304Land 316Laresusceptibleto chloride stress corrosion cracking(SSC) under certain conditions. Resistance to SSC increases with the increased content of nickel and molybdenum. Therefore, the higher performance austenitic stainless steels such as 904L have very good resistance to SSC.

WELDING

Alloy 904L can be readily welded by most standard processes. Austenitic plate materials have a homogeneous austenitic structure with an even distribution of alloying elements. Solidification after welding causes the redistribution of certain elements such as molybdenum, chromium and nickel. These segregations remain in the cast structure of the weld and can impair the corrosion resistance in certain environments. Segregation is less evident in 904L, and this material is normally welded using a filler metal of the same composition as the base metal and can even be welded without filler metal. The welding consumables for 904L are 20 25 CuL covered electrode

HEAT TREATMENT

Working temperatures of 1562 – 2102°F (850 –1150°C) are recommended for hot working processes. Normally hot working should be followed by a solution anneal and quench, but for 904L, if hot forming is discontinued at a temperature above 2012°F (1100°C) and the material is quenched directly thereafter, the material may be used without subsequent heat treatment. It is important that the entire work piece be quenched from temperatures above 2012°F (1100°C). In the event of partial heating or cooling below 2012°F (1100°C), or if the cooling has been too slow, hot working should always be followed by a solution anneal and quenching. 904L should be solution annealed at 1940–2084°F (1060–1140°C)