JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

|

Verified Suppliers

|

|

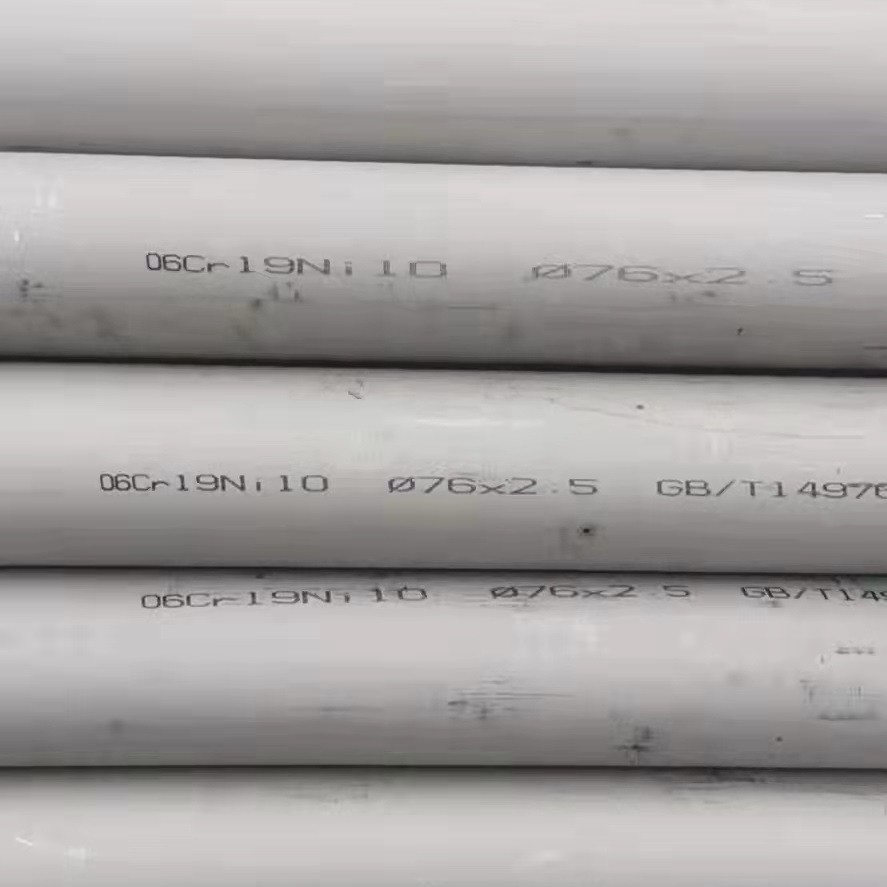

Low Carbon 304L Stainless Steel Seamless Pipe Tube SCH40 DN10-300 in 6m Length

Our company is a Specialized supplier of ASTM A269 TP304L Stainless Steel Tubing, ASTM A213 304L, ASME SA213 TP304L Stainless Steel Tubes, SS 304L Tubes, ASTM A312 SA312 TP304L Stainless Steel Pipe, Stainless Steel 304L Pipes, ASTM A213 SA213 304L U bend Tubes, EN 10216-5 1.4307 Stainless Steel Tubes in China.

ASTM A213 A312 A269 A511 A240 UNS S30403 304L, EN 10216-5 1.4307 stainless steel pipe is a variation of the 18% chromium – 8% nickel austenitic alloy, the most familiar and most frequently used alloy in the stainless steel family. This alloy may be considered for a wide variety of applications and exhibits good corrosion resistance, ease of fabrication, excellent formability, and high strength with low weight. Type 304L is a lower carbon variant of Grade 304 – the steel can be welded without the resulting issue of carbon precipitation precipitation of chromium carbide as heat is applied during the welding process which depletes the chromium element of the steel thus reducing its anti-corrosive / oxidation effectiveness, and because of low carbon percentage, can minimizing Intergranular corrosion attack.

As a result, Type 304L seamless tubing is a sort after material for use in severely corrosive conditions. Weld annealing is only necessary in applications where stress loads are excessive. This steel Grade is found in a variety of commercial sectors, particularly in the chemical industry. 304 & 304L have similar properties and in certain cases are stocked with Dual Certification, where it is concluded that each item has properties and a composition which comply with both steel types. Grade 304H cannot be included in this equation due to the steel’s higher carbon content which is intended for use in elevated temperature applications.

L-grades have 0.035% carbon maximum. L-grades are resistant to sensitization in short-term exposures or heat treatments. L-grade often have slightly lower (typically 30MPa less) minimum strengths than standard stainless steel.

OD: 3.175 – 508mm (1/8 – 20 Inch) , WT: 0.50 – 63.5mm (0,02 – 2 1/2 inch), Length: 25000mm Maximum

| Grade | – | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 304/S30400 | min.max. | -0.08 | -2.0 | -1.00 | -0.045 | -0.030 | 18.0-20.0 | – | 8.0-11.0 | – |

| EN 10216-5 1.4301 | min.max. | -0.07 | -2.0 | -1.00 | -0.040 | -0.015 | 17.00-19.5 | – | 8.0-10.5 | -0.11 |

| 304L/S30403 | min.max. | -0.035 | -2.0 | -1.00 | -0.045 | -0.030 | 18.0-20.0 | – | 8.0-12.0 | – |

| EN 10216-5 1.4307 | min.max. | -0.030 | -2.0 | -1.00 | -0.040 | -0.015 | 17.5-19.5 | – | 8.0-10.0 | -0.11 |

| 304H /S30409 | min.max. | 0.04-0.10 | -2.0 | -1.00 | -0.045 | -0.030 | 18.0-20.0 | – | 8.0-11.0 | – |

| EN 10216-5 1.4948 | min.max. | 0.04-0.08 | -2.0 | -1.00 | -0.035 | -0.015 | 17.0-19.0 | – | 8.0-11.0 | -0.11 |

Typical mechanical properties for grade 304 stainless steels are given in table 2.

Table 2. 304L Stainless Steel Tubes Tubing Mechanical properties

| – | Tensile Strength | Yield Strength | Elongation | Hardness | Hardness |

| Grade | (MPa) min | 0.2% Proof (MPa) min | (% in 50mm) min | Rockwell B (HR B) max | Brinell (HB) max |

| 304 | 515 | 205 | 35 | 90 | 192 |

| 304L | 485 | 170 | 35 | 90 | 192 |

| 304H | 515 | 205 | 35 | 90 | 192 |

304H also has a requirement for a grain size of ASTM No 7 or coarser.

| Products | ASME SA213 TP304L Stainless Steel Tubes |

| Condition | Annealed and Pickled |

| Hardness Rockwell HRB | 78 |

| Tensile Strength Mpa | 593/595 |

| Yield Strength Mpa | 265/268 |

| Elongation % | 52-53 |

| 304L Stainless Steel Pipe Density (lb / cu. in.) | 0.29 |

| Specific Gravity(kgs/dm³) | 7.93 |

| Specific Heat (Btu/lb/Deg°F – [32-212 Deg °F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg °F)) | 432 |

| Melting Point (Deg°F) | 2650 |

| Modulus of Elasticity Tension | 28 |

| GRADE | UNS | EN | JIS | AFNOR | BS | WERKSTOFF NR. | GOST | SS |

| USA | EUROPE | JAPAN | RUSSIAN | BRITISH | GERMAN | RUSSIAN | SWEDISH | |

| SS 304L | S30403 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | Z3CN18‐10 | 304S11 | 1.4306/1.4307 | 03Х18Н11 | 2332 |

| Standard Specification: | EN 10216-5, DIN 17456, DIN 17458, DIN 2462, DIN 17455 |

| GB/T14975, T14976, T13296, GB5310 | |

| ASTM A213, A269, A312, A511, A789, A790, A928, A999, A1016, ASTM B161, ASTM B163, ASTM B165, ASTM B167, ASTM B338, ASTM B407, ASTM B423, ASTM B444,ASTM B619, ASTM B622, ASTM B626, ASTM B668, ASTM B677, ASTM B829 | |

| JIS G3459, JIS G3463, JIS G3446, JIS G3447, JIS G3448, JIS G3468 | |

| GOST 9940, GOST 9941 |

| TP304L Stainless Steel Principal Design Features |

| A low carbon version of type 304 stainless. 304L is used almost interchangeably with 304 but is preferred for welding operations. It offers a good combination of strength, corrosion resistance and fabricability. |

| 304L Stainless Steel Applications |

| Almost every conceivable industry uses some of this material in some way. Everything from stovetops to ball point pen barrels to flatware to fasteners has been fabricated from this alloy. |

| TP304L Stainless Steel Pipe Machinability |

| Slow speeds and heavy feeds will minimize this alloys tendency to work harden. Due to long stringy chips, the use of chip breakers is advisable. Many companies now offer premium machinability grades, such as CarTech with their Project 70 and 7000 series. |

| 304L Stainless Steel Tubing Welding |

| All fusion and resistance processes have been successfully employed in welding 304. AWS E/ER308 or 312 filler metal is recommended. Its low carbon, means that the is less carbide precipitation at the weld boundaries resulting in stronger welds. |

| TP304L Stainless Steel Pipe Hot Working |

| Forging, heading and other hot working should follow uniform heating to 2100-2300°F (1149-1260°C). Rapid cooling is necessary to attain maximum corrosion resistance in finished parts. |

| 304L Stainless Steel Tubing Cold Working |

| Readily fabricated by most cold working methods, 304L may require intermediate annealing to avoid cracking or tearing from radical deformation. Full annealing should follow any operation to reduce internal stress and optimize corrosion resistance. |

| 304L Stainless Steel Pipe Annealing |

| 1850-2050°F (1010-1121°C) ,rapid cooling Quenching in water or Oil. 304L Stainless Steel Tube are normally delivered in heat treated condition. If additional heat treatment is needed after further processing the following is recommended. Stress relieving 850-950 °C (1560-1740 °F), cooling in air. |

| 304L Stainless Steel Pipe Hardening |

| This alloy does not respond to heat treatment. Cold work will cause an increase in both hardness and strength. |

American standard for Process piping (ASME B31.3 : 2018)

Maximum internal pressure of ASTM A312 A269 304L Size: OD 15.88mm WT 1.245mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 171 | 171 | 171 | 161 | 151 | 143 | 138 | A 312 and A 269 tube |

Maximum internal pressure of ASTM A312 A269 304L Size: OD 15.88mm WT 1.651mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 232 | 232 | 232 | 218 | 206 | 195 | 188 | A 312 and A 269 tube |

Maximum internal pressure of ASTM A312 A269 304L Size: OD 19.05mm WT 1.651mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 191 | 191 | 191 | 179 | 169 | 160 | 154 | A 312 and A 269 tube |

Maximum internal pressure of ASTM A312 A269 304L Size: OD 19.05mm WT 2.11mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 249 | 249 | 249 | 234 | 221 | 209 | 201 | A 312 and A 269 tube |

Maximum internal pressure of ASTM A312 A269 304L Size: OD 25.4mm WT 1.651mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 141 | 141 | 141 | 132 | 125 | 118 | 114 | A 312 and A 269 tube |

Maximum internal pressure of ASTM A312 A269 304L Size: OD 25.4mm WT 2.11mm Wall Thickness Tolerance: ± 10%

| Grade | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Pressure bar | Remark |

|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F | – | |

| 304L | 183 | 183 | 183 | 172 | 162 | 153 | 148 | A 312 and A 269 tube |