JIANGSU GUOJIN DRYING TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

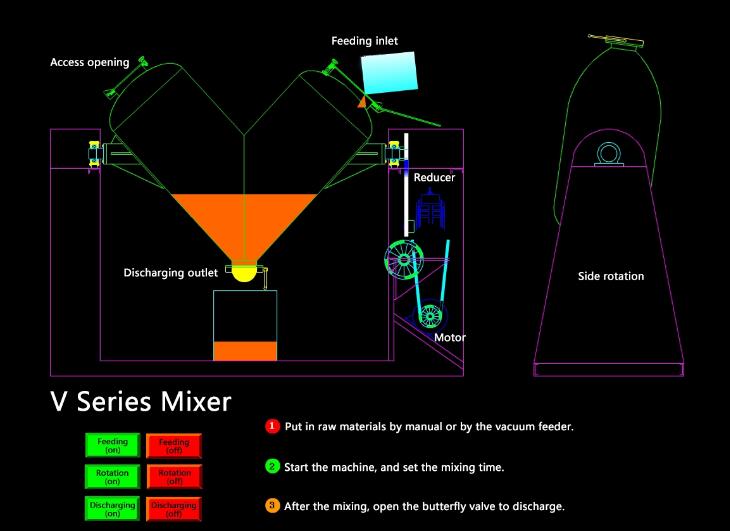

V 200 Type Lab Pharmaceutical Vertical Dry Powder Mixer Machine

This machine adopts labor feeding and enclosed flapper valve for discharging. It will not produce powder dust, and it also will not produce mechanical compression and strong friction during mixing. So the material particles can remain intact.

The mixing barrel is made of stainless steel, which won’t pollute the material. Besides, this machine has timing device, which can control the mixing time of materials.

The mixer is used in pharmaceutical, chemical, food, metallurgy, construction and other industries. For the different proportion, or different proportion with the proportion of powder materials mix.

1. Connect the power first, setting the required mixing time, then turn on the switch, the machine begin running.

2. After the mixing, if you found that the position of discharging port is not the best position, you should turn off the power first, and adjust the position of discharging port.

3. Before you use the machine, you should check the appliance, if it is normal; and check the covers of mixing barrels, if the covers are tightly closed.

4. User should clean the machine after the finish of work, especially the barrels, prevent the residual materials.

5. Note that the reducer should be added enough lubricating oil(generally use the 30 # machine oil), and the transmission should be added grease lubricant.

6. Users should maintain the machine once each half of year, change the lubricating oil of reducer, check if the appliance is aging, the appliance should be replaced if it is aging.

7. After you have been using the machine for one year or more, you should make a big maintenance, check the gab between each parts, and appropriately adjust them, so that the machine can keep in good condition.

Technical Parameters

| Model | 0.18 | 0.3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 |

| Productive capacity(kg/batch) | 72 | 120 | 200 | 400 | 1600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Model of vacuum pump | W2 | W2 | W2 | W3 | W3 | W3 | W3 | W4 | W4 | W4 |

| Time of raw material fed in(min) | 3-5 | 3-5 | 4-6 | 6-9 | 6-10 | 8-13 | 8-15 | 8-12 | 10-15 | 15-20 |

| Mixing time(min) | 4-8 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 8-12 | 8-12 | 8-12 |

| Total volume(M3) | 0.18 | 0.3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 |

| Stirring speed(r/min) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 10 | 10 | 10 |

| Motor power(kw) | 1.1 | 1.1 | 2.2 | 4 | 4 | 5 | 7.5 | 7.5 | 11 | 15 |

| Rotating height(mm) | 1580 | 1760 | 2400 | 2840 | 3010 | 3240 | 3680 | 3700 | 4350 | 4800 |

| Weight(kg) | 280 | 320 | 550 | 950 | 1020 | 1600 | 2040 | 2300 | 2800 | 3250 |

Technological Process

Production Show

electrical, steam, natural gas or other