JIANGSU GUOJIN DRYING TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

Continous Working Industrial Sand Rotary Dryer

Rotary drum dryer mainly consists of rotary body, raw material feeding plate, driving and supporting device, etc. Its principle of operation: the raw material feeding plate which is arranged reasonably with changeable angles in order, throws moisture materials into the rotary cylinder. Then water will be separated from the materials by hot air-flow and be changed into vapour to be excreted to the air. Thus, the drying process is finished.

Product Features

1, It can change operation parameters according to different material property, the rotary drum dryer can form full section material fall which makes the heat exchange more fully;

2, New type feeding and discharging devices completely eradicate the disadvantages of traditional dryer like feeding jams, feeding discontinuously and unevenly, returning materials, and reduce the load of dust removal system ;

3, Scale plate sealing is used to connect shell and feeding and discharging device , good sealing greatly reduce the shell internal heat loss, thus directly reducing the fuel consumption;

4, Counter-current drying method obtains higher evaporation intensity; Fair current drying method and indirect drying way are suitable for drying temperature sensitive material;

5, New burner satisfies the customers’ demand for saving energy and high efficiency. It can choose diesel oil, heavy oil, natural gas, coal gas etc. to be fuel instead of the only choice for coal as fuel in the past.

Product Working Principle

When the damp raw material is fed from one terminal, it is turned over through blades that are distributed inside the cylinder and will be distributed uniformly in the drier and contact fully with the counter current hot air. In this way, the process of heat conduction is increased. During the period of dry, inder the effect of incine blades and hot air steam, raw material can be moved to dried and discharged from discharged form discharging valve.

Product Application

(1) Ore:ore, slag, mineral power, limestone, quartz, fluorite

powder, iron ore, metal ore concentrates, metal tailings,etc.

(2) Metal: metal powder, iron powder, iron filings, steel scrap,

copper filings, etc.

(3) Chemical industry: gypsum powder of desulphurization gypsum

stir-frying half water model and building gypsum

powder,clay,diatomaceous earth, kaolin,bauxite

(4) Coal: raw coal,coal slime, coal,coal ash,coal cinder

(5) Sand: sand,quartz sand,moulding sand,river sand

(6) Various crystals: light calcium carbonate, activated clay,

magnetic powder, graphite, mineral mud, clay, lime slurry, ore

slurry, phosphorus slag, aluminum red mud, feldspar powder, fly

ash, blue carbon, potassium, sodium, calcium, barium and alkali

metal or silicate minerals in the alkali metal.

(7) Wood: sawdust, small wood chips, wood veneer.

(8) Fertilizer: compound fertilizer, organic fertilizers, inorganic

fertilizers, ammonium sulfate fertilizer

(9) Agriculture: straw, grass, turf.

(10) Animal manure: chicken manure, duck manure, cow dung, etc.

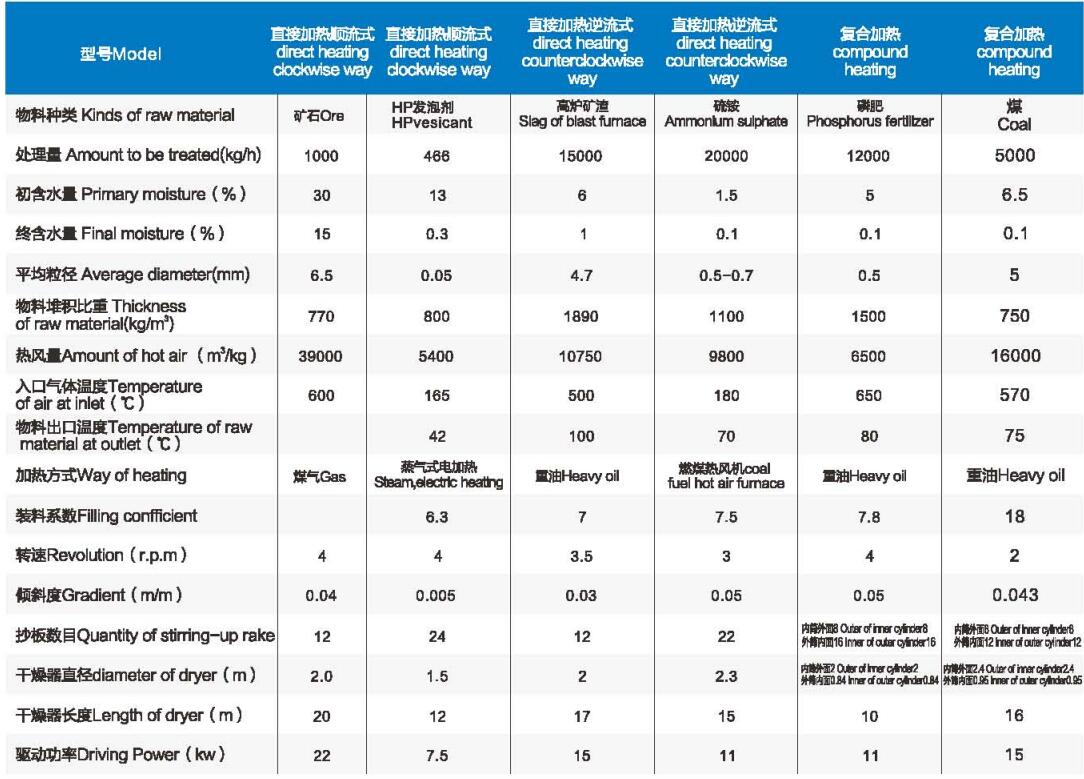

Technical Parameters

| Item | Productive capacity(t/h) | Revolution(r/min) | Motor power(kw) | Install angle(o) | Temp. of final |

| Ø1.0x5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | <1.5% |

| Ø1.2x6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | <1.5% |

| Ø1.5x12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | <1.5% |

| Ø1.8x12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | <1.5% |

| Ø2.2x12-22 | 7-12 | 0.6-6 | 22 | 3-5 | <1.5% |

| Ø2.4x15-20 | 9-15 | 0.6-6 | 30 | 3-5 | <1.5% |

| Ø3.0x25 | 16 | 0.6-6 | 55 | 3-5 | <1.5% |

Production Show

electrical, steam, natural gas or other