JIANGSU GUOJIN DRYING TECHNOLOGY CO., LTD |

|

Verified Suppliers

|

|

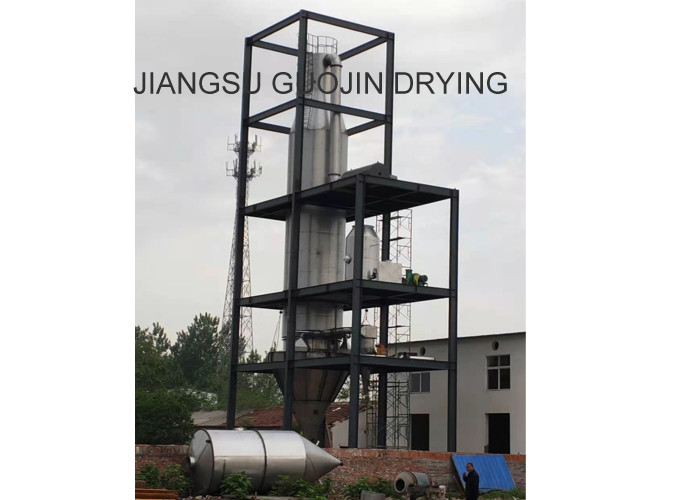

500kg/h Water Evaporation 19M Height Chemical Pressure Nozzle Spray Dryer

The material is sprayed into fine mist by nozzle on the top of tower. Follow the heat wind, the material is dried. The machine's characteristic is high collection rate, no stick onto the wall, energy saving, high efficiency, especially applicable for heat sensitive material. It's widely used in food, dyestuff, chemical industry and so on.

Working Principle

After fresh air is filtered and heated, it enters into the air

distributor which on the top of the drier. The hot air in spiral

form equably enters into the drying room. When liquid raw material

is passed through the high-speed centrifugal sprayer on the top of

the tower, it will be rotated and sprayed into the extreme slim

mist liquid beads. Raw material can be dried to the final products

instantly while it contact with the heated air. Finished products

are discharged continuously from bottom of the drying tower and

cyclones segregator. Wasted air is discharged from the blower.

Features

1. The tower is equipped with a cold air jacket;

2. The towers is equipped with automatic vibration device;

3. There are quick opening cleaning hole and sewage hole in the

tower and piping system;

4. The dryer can be equipped with automatic control &

thermostatic feeding tank;

5. Manual supplied accessories for the high-pressure washing system

is available;

6. The material contacting area is constructed by stainless steel;

(or use all stainless steel);

7. The material is collected by two-stage cyclone dust collector.

Or use a cyclone operator and wet dust collector instead;

8. The inlet air temperature can be controlled by a continuous

automatic control device.

9. The dryer can be equipped with gas cleaning device.

Application

Chemical industry: Sodium Fluoride (Potassium ), Alkaline Dyestuff And Pigment,Dyestuff Intermediate, Mn3o4, Compound Fertilizer, Formic Silicic Acid, Catalyst, Sulphuric Acid Agent, Amino Acid,White Carbon, and etc.

Food Industry: Fatty Milk Powder, Protein, Cocoa Milk Powder,

Subsitute Milk Powder,Egg White (Yolk), Food And Plant,Oats,Chicken

Juice, Coffee, Instant Dissoluble Tea ,Seasoning Meat,Protein

,Soybean,Peanut Protein, Hydrolysate, Sugar,Corn Syrup,Corn

Starch,Glucose, Pectin,Malt Sugar, Sorbic Acid Potassium, and etc.

Pharmaceutical Industry: Chinese Traditional Medicines, Pesticide,

Antibiotic, Medical Drinking Agent,and etc.

Plastics and Resin: AB, ABS Emulsion, Uric Acid Resin, Phenolic

Aldehyde Resin, Urea-Formaldehyde Resin, Formaldehyde Resin,

Polythene, Poly-Chloroprene, And etc.

Detergent: Common Washing Powder,Advanced Washing Powder,Soap

Powder, Soda Ash, Emulsifier, Brightening Agent, Orthophosphoric

Acid, and etc.

Ceramic: Aluminium Oxide, Ceramic Tile Material, MagnesiumOxide,

Talcum, and etc. Other: Calmogastrin, Hime Chloride , Stearic Acid

Agent, and etc.

Other: Calmogastrin, Hime Chloride , Stearic Acid Agent, and etc.

Technical Parameter

| Model | PNSD-25 | PNSD-50 | PNSD-100 | PNSD-150 | PNSD-200 | PNSD-300 | PNSD-500 | PNSD-1000-2000 | |

| Water Evaporation capacity | 25 | 50 | 100 | 150 | 200 | 300 | 500 | The index can be affirmed in accordance with practical conditions. | |

| Diaphragm pump | Power(KW) | 0.35 | 4 | 7.5 | 11 | 15 | 22 | 30 | |

| Pressure(Mpa) | It can be regulated from 0.6 to 5, in general, it will be from 1 to 3. | ||||||||

| Heating way | electricity | electricity+steam | electricity+coal fuel oil hot air furnace | ||||||

| Diameter of tower body(mm) | 1300 | 1800 | 2400 | 2600 | 2800 | 3200 | 3800 | ||

| Total height(mm) | 7800 | 9200 | 11600 | 14000 | 15300 | 17100 | 19000 | ||

| Remark | 1. The evaporated amount is related to characteristics of raw material. The evaporated amount listed in the table is related to temperature. The data can be used for reference only. 2. The atomizing pressure and Model of pump will be equipped in accordance with the amount of raw material to be treated and the size require of product. 3. The power of fan should be iincreased suitably after equipped with cloth bag duster. | ||||||||

Product Show