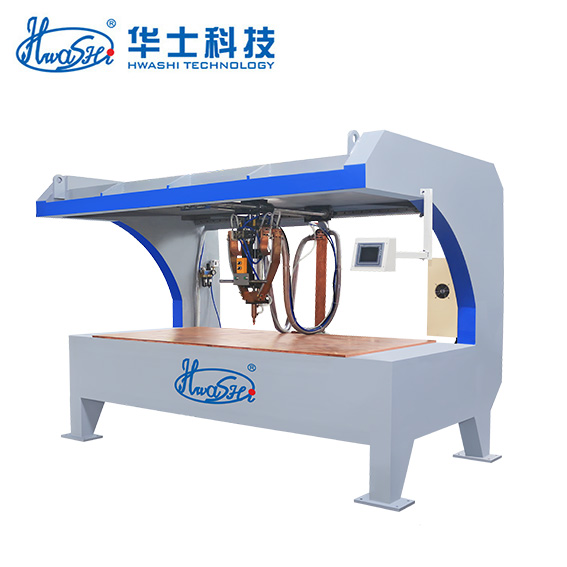

Hwashi Door Plate Crank Arm Spot Welding Machine

Our machines have been widely applied to various kinds of

industries, such as kitchen utensils, automobile making, motorcycle

manufacturing, glasses, hardware, household appliances, low-voltage

apparatus, elevator, compressor, etc.

Description

Crank-arm mobile flat table spot welder is designed with multiple

mobile arms according to the principle of mechanical arm, which can

automatically or manually move in order to ensure the precise

preset position of welding spot. AC pulse, three-phase secondary

rectifying or medium frequency inverter power source are optional

to be the welding power source.

Features

1. The movement patterns of crank arm mobile flat plate spot welder

can be chosen as manual or CNC automatic mobile type. 2. The

structure of manual mobile method is simple. It is convenient,

flexible to move manually and the locating of welding spot is

simple. Good applicability to complicated products. 3. Automatic

mobile method adopts the coding servo motor, which is equipped with

precision-machined good quality of slide rail, ball screw and

automatic testing system in order to complete the electrode

automatic movement. Quick response, high precision of control.

Automatic device adopts the X, Y axis of mobile working table,

utilizing the PLC to store setting mobile program. Simple and

convenient setting. 4. Adopt direct single-point welding method.

The lower electrode is designed as complete flat, which is suitable

for welding of flat plate with multiple welding spots on the

surface and be able to guarantee both the smoothness of surface and

the consistency of welding spots.

Material Configuration

1. Adopt the energy storage quick charge-discharge capacitor from

Japan Nippon Chemi-Con (NCC) which is the original MARGON or

HITACHI; Fast discharge rate. Stable performance. 2. Adopt SEMIKON,

IXYS from West Germany or Silicon controlled of IR from United

States. High precision and durable. Be able to achieve high stable

control on the magnitude of current. 3. Adopt Motorola integrated

circuits from United States. Quick reaction. Stable performance. 4.

Adopt pneumatic parts from Japan or Taiwan. Reliable performance.

5. All the devices are from imported famous brands. Ideal service

life and performance. We have professional production team,

production line, experienced technical experts who engaged in this

industry for more than 20 years. The main products of our company

include capacitor discharge spot welder, pneumatic AC pulse spot

welder, three-phase secondary rectifying spot welder, medium

frequency inverter spot welder, precision micro spot welder and

high degree of automatic welding machine.

Specification

S.N | Items | WL-MF-75K |

1 | Input voltage | 380V,3 phases |

2 | Input current | 80A |

3 | Output voltage | 12V |

4 | Max.Welding Current | 26000A |

5 | Welding Specification | 18 kinds |

6 | Different Welding Current | 6 kinds |

7 | Effective size of welding platform | 2000mmx800mm |

8 | Max.range of Crank moving | 1200mm |

9 | Max.angle of Crank moving | 180° |

10 | Adjusting rang of platform height | 0-200mm |