GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

APPLICATION

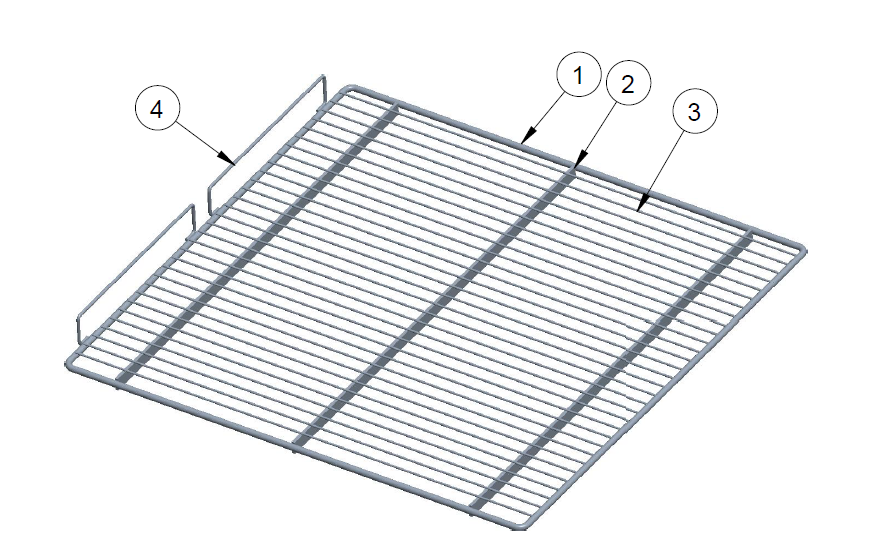

Retangular Frame: Wire diameter: φ6mm size: 460x473.5mm

Retangular Support: 3x12mm Length: 446mm

Wire diameter: 2-3mm

Production Line Composition

Step 1: Round Wire Straightening and Cutting

The high-speed steel wire straightening and cutting machine is developed and designed by our company in combination with the advantages of various models at home and abroad. The wire feeding speed can reach maximum 120m/min, the surface is free from scratches, the cutting length error is ±0.5mm, the length is automatically adjusted by the host, and the man-machine integrated touch screen control The system can set the output preset and the lack of material alarm. We can separate the machine into several range: 1.1~1.5mm/ 1.6~3mm/ 2~4mm / 3~5mm / 5~7mm.

Step 2: Frame Bending Machine

The automatic wire bending machine adopts hydraulic joint drive to automatically bend the metal wire into various specifications of square, rectangular, U-shaped, trapezoidal, etc. It is widely used in logistics trolleys, storage cages, shelves, barbecue nets and other industries. It can bend 4 to 6 pieces of wire frame at the same time. So it can achieve higher production output.

Step 3: Frame Butt Welding Machine

Frame butt welding machine for Joining the frame ends after bending

Double-head T butt welding machine for Joining the frame middle bars to the outer frame

Manual moving the fixture, automatic welding.

Step 4: Automatic Wire Shelf Welding Machine

1. This Gantry Row welding machine is specialized in fast production of wire mesh. It is suitable for the product with more y wire and less x wire.

2. The welding power source could be two-phase AC or three-phase MF DC. The welding manner is one-way double-layer automatic stepping feeding with multiple welding heads. (adjustable according to your product). If you want higher welding efficiency, you can add more welding power source. One set of power source is able to control one welding electrode to do welding. Normally we will suggest to use two sets of power source or more.

3. The effective welding width is 1000mm while the effective welding length is 500mm. (The welding range can be customized according to your products) For example, if the product size is 460x473.5mm, we can weld two pieces of product at the same time.

4. Automatic wire filling system is optional. You can choose to use the automatic wire loading of the middle wires or you can choose manual wire loading.

Step 5: Wire Edge Trimming Machine

After welding, we will need the trimming machine to cut off the extra wires to make the frame smooth.

This machine is mainly used for the peripheral trimming of wire metal mesh. The trimming diameter is φ3-φ8. The size of the trimming mesh is not limited. It can be completed with the assistance of auxiliary tooling. The cutting speed is fast and the port is flat. The machine is composed of a frame and a drive. Components, eccentric mechanism, headstock, cutter components, control components, composed of six parts.

Step 6: Side Handle 2D Bending Machine

2D machine is for bending the side handle into U shape.

The design concept of this equipment is to use machines instead of labor, and can be produced without straightening mechanism or mold opening. As long as the product is on a plane, various shapes can be formed. Mainly used for iron wire, stainless steel wire, copper wire, aluminum wire forming (bending) various irregularly shaped flat products, such as square, round, hexagonal, oval, various buckles, various hooks and different circle diameters Different curved wires.

Step 7: Side Handle T Butt Welding Machine

After 2D bending of the side handle, you may need this T butt welding machine to join the handle to the outer frame.

FAQ:

Question 1: Can I get the complete technical proposal for Refrigerator Wire Shelf Welding Machine Production Line?

Answer 1: Yes. Sure. Please send your product drawings to my email, indicating the wire diameter, minimum and maximum size, your required welding efficiency, etc. Then we will prepare the complete technical proposal with quotation for you.

Question 2: Have you sold this Refrigerator Wire Shelf Welding Machine Production Line before?

Answer 2: Yes. We have cooperated with companies from India,South Korea,Vietnam, Malaysia, Russia, Poland, USA, Colombia, etc. If you want to know the detailed information, please contact with us.

Question 3: What's the delivery time for the complete Wire Shelf Welding Machine production line?

Answer 2: Normally it will take about 30-60 workding days for us to complete the machine. It depends on the machines you choose.