GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Hwahsi Automatic Double Bending Shrinking Machine for IBC Stainless Steel Frame Tube Bending Forming Pipe Tube Bending Machines

IBC Short Tube Automatic Pressing and Forming Machine is a special customized machine for IBC tube processing. It can achieve full automatic pipe feeding, pipe end forming and cutting, pipe hydraulic pressing, and automatic unloading process. No operator needed. It helps to greatly increase the production rate, and save manpower.

Full Automation: The IBC Short Tube Automatic Pressing and Forming

Machine operates entirely through automation, eliminating the need

for manual intervention.

Highly Efficient Production: The machine's automated functions

greatly increase production speed, reduce processing cycles, and

thereby improve overall production efficiency.

Controlled Pipe Quality: A precision control system ensures the

quality of pipe forming, meeting relevant standards and

requirements.

Manpower Savings: Due to the machine's fully automated operation,

continuous human supervision is not required, saving on manpower

and reducing production costs.

Multi functional Design: The machine integrates multiple functions,

including pipe feeding, forming, cutting, hydraulic pressing, etc.,

into one unit, achieving a one-stop processing solution and

enhancing overall production line efficiency.

The IBC Short Tube Automatic Pressing and Forming Machine holds

significant potential in the IBC tube processing industry,

providing businesses with an efficient, precise, and cost-saving

production solution.

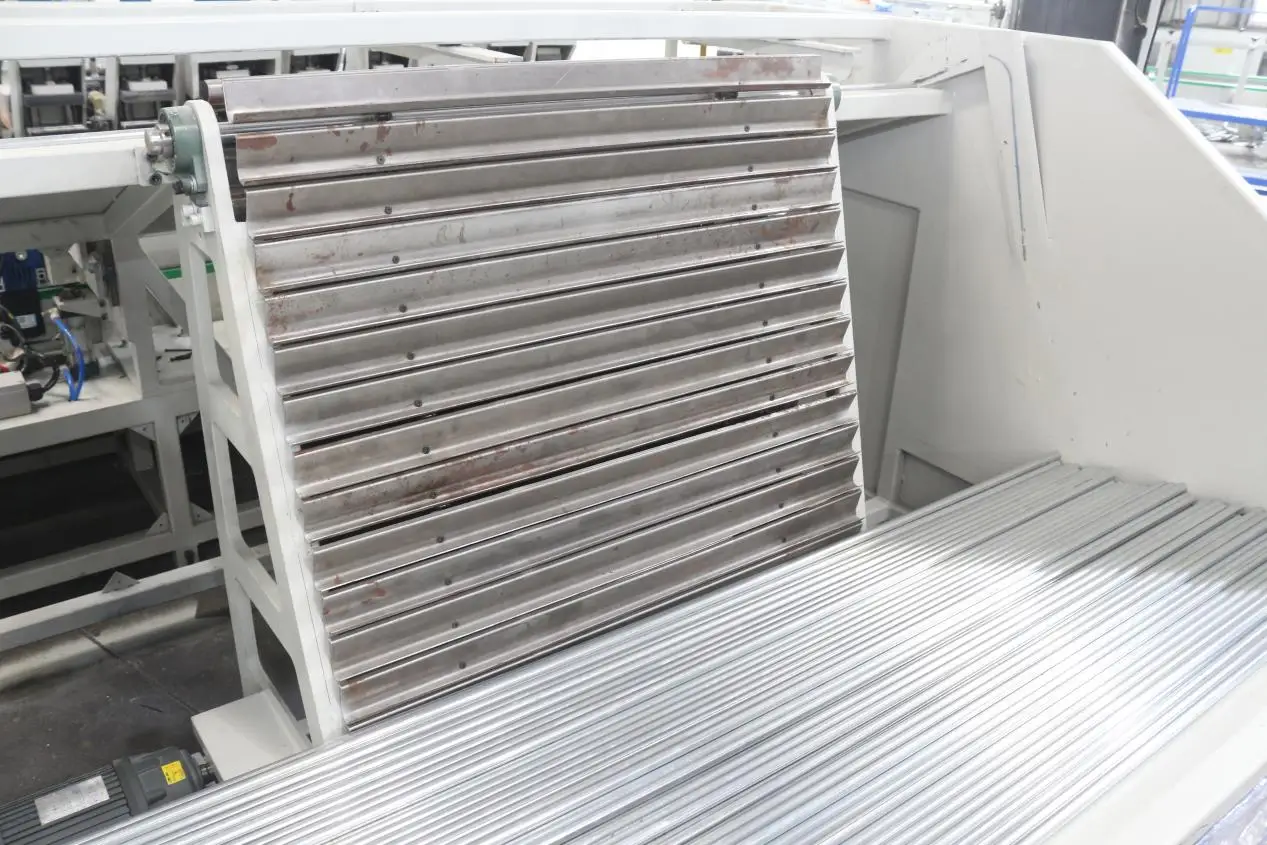

Manually load the round tubes before processing into the hopper. The feeder will load the pipe to the hydraulic pressing station automatically. | The mechanical arm will pick up the tube and load it to the hydraulic pressing station to do the pressing and tube end shrinking.

|

| After pressing, the tube will be loaded to the bending station to do the bending into square shape. After bending, the tube will be unloaded to the frame and stacking automatically. | Finished Product |

| Items | Data |

| Pipe Diameter | Round pipe 18mm (customized) |

| Pressing Source | Hydraulic |

| Pressing Mark Number | 8 |

| Cutting Function | Yes |

| Each Time Processing Number | 2 pcs |

| Efficiency | 12-15sec/2pcs |