GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Single / Multi Head Row Welding Machine

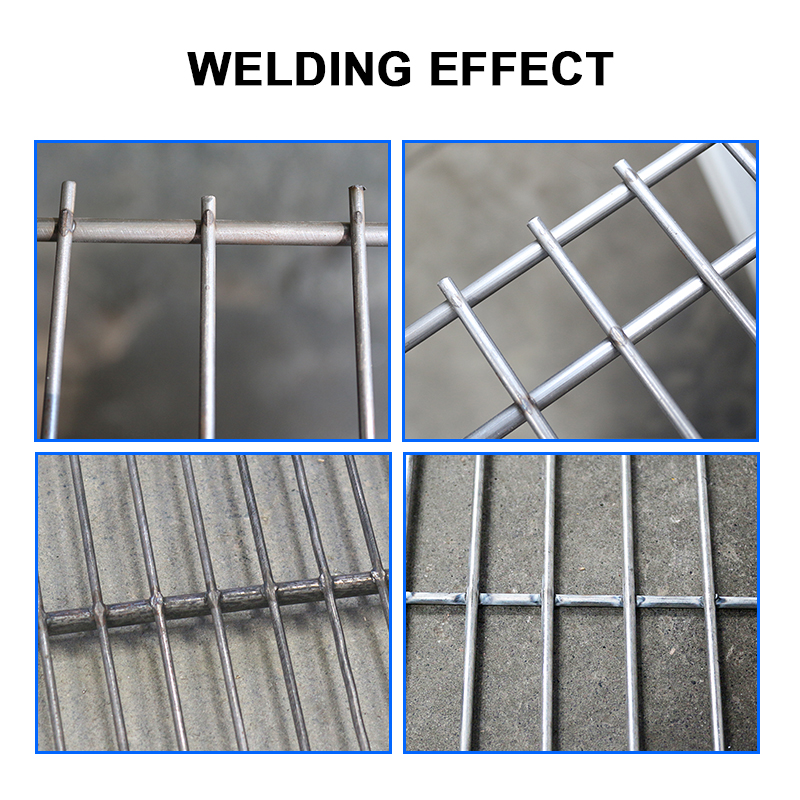

Custom Welding Electrode According to the characteristics of the mesh, the appropriate welding electrode is processed. | Single/Multiple Welding Head Design multiple welding heads according to different sizes of mesh, and the welding efficiency is higher. |

Longer Welding Arm

Production of extended welding arm, suitable for various sizes of mesh. | Manual/Automatic Welding According to each customer demand, provide manual welding type and automatic welding type. |

Product Description

1.This Gantry Row welding machine is specialized in fast production of wire mesh. It is suitable for the product with more y wire and less x wire. 2.The welding power source could be two-phase AC or three-phase MF DC. The welding manner is one-way double-layer automatic stepping feeding with multiple welding heads. (adjustable according to your product)

3.The effective welding width is 1200mm while the effective welding length is 3000mm. (adjustable according to your product)

Features

1. Main body: It adopts longitudinal stress body and good quality thick steel plate to ensure the strength and stability of the main body.

2. Welding Control System: The secondary which is controlled by microcomputer will identify the output of current automatically in order to guarantee the constant current of each welding spot. In the meantime, the control system is equipped with the function of voltage compensation which is used for the automatic detection of the voltage change in order to ensure the constant strength of the welding spot.

Pressurized Mechanism: Multiple pressurized mechanisms are adopted to drive the row welding electrodes to conduct welding to each wire respectively.

APPLICABLE AREA

Suitable for batch production of wire mesh.

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out with the suitable technical proposal based on your samples or drawings.