GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Hwashi IBC Cage Frame Automatic Locking Machine Automatic Frame

Clinching Machine

This IBC cage frame clinching machine is a part of the IBC

frame production line. It is used to lock the tube mesh edges after

welding. The machine frame is processed as a whole, with high insertion

precision, large fastness to locking, stable and efficient

operation.

2. The machine is controlled by human-machine interface +PLC

programming control mode, with high degree of automation.

1. According to the different designs of IBC metal cages, the adjustable locking arm can make the machine's working range wider.

2.The hydraulic and pneumatic design of the locking arm can make the machine more efficient.

3. The design of the fastening arm can automatically insert the pipeline.

4. Using a hydraulic system to lock the mesh can make the pipe fittings firmly connected and prevent cracking of the metal cage.

5. The metal cage feeding device can make automatic cage production more stable and efficient.

Production Capacity: 25-30sec/pc

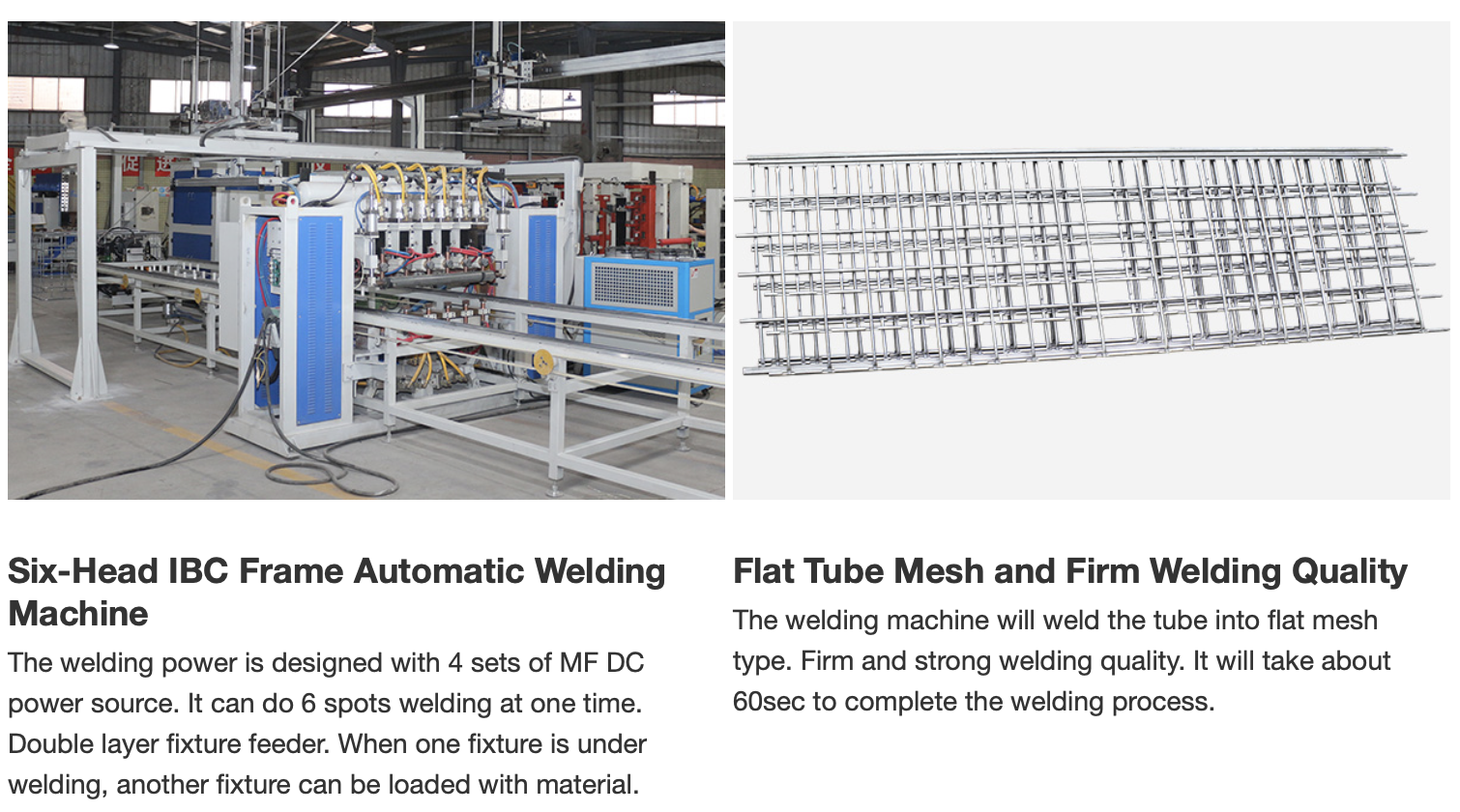

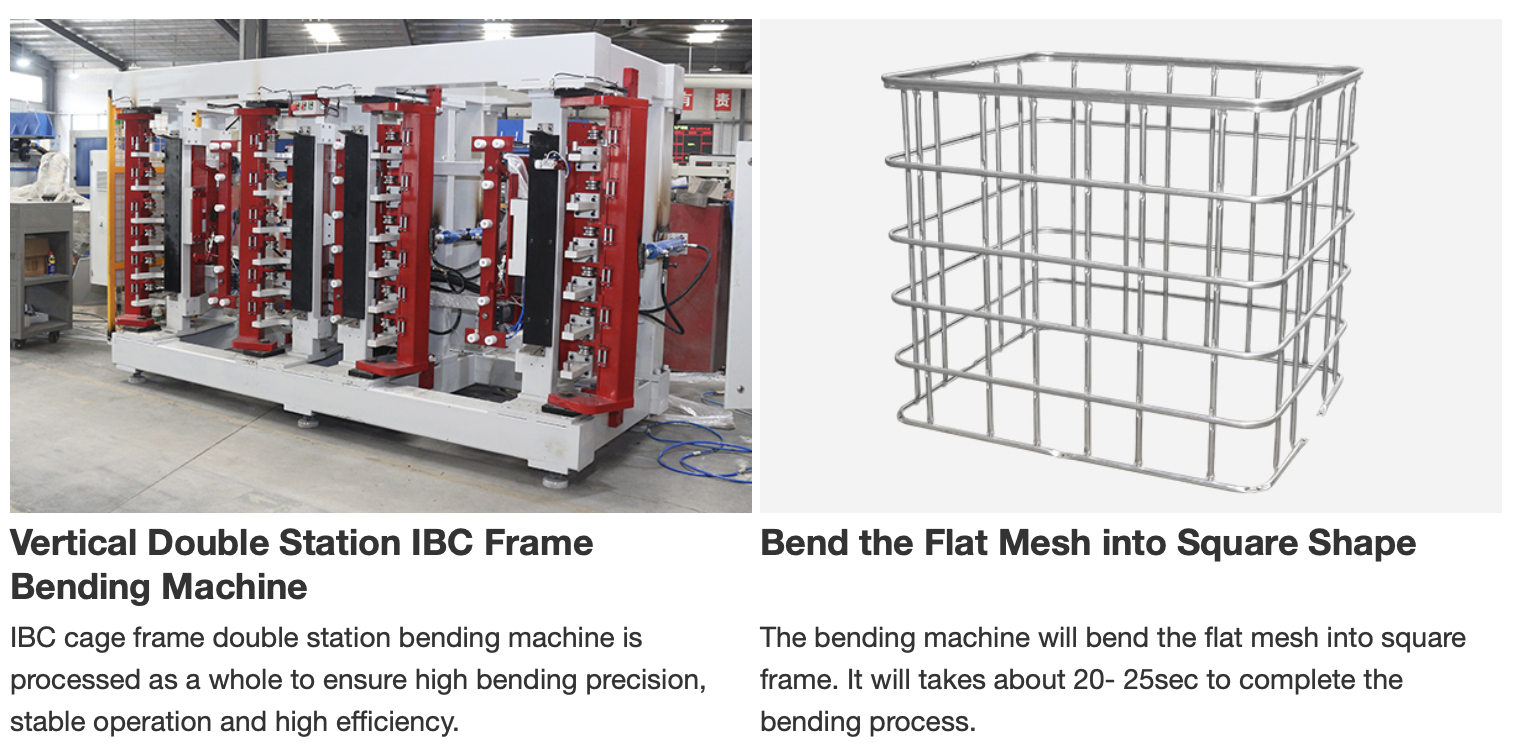

IBC Tank Cage Frame Production Line Machine

This automatic production line is mainly used to manufacturing the

IBC cage frame. It is composed of cage frame automatic welding,

mesh unloading mechanical arm, mesh turnover structure, automatic

frame bending machine, locking machine, hole making and punching

machine, automatic production line moving mechanical arm. The

complete line requires only 3-4 person. Operator only need to do

the material loading to the frame welding machine, and do unloading

at the end of the line. Also we can equip the line with automatic

base frame welding machine and automatic unloading mechanical arm

for the base frame.

Running process:

Frame welding——bending——locking——hole punching——unloading——base

frame welding——base frame loading——manual screw for base frame and

outer frame

Inner tank loading——automatic valve welding——leakage

detection——automatic cover tightening——put the tank into the

frame——manual assembly of the pull rod——complete product stacking