GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Capacitor Projection Welder for BRAISER , SOUP POT , STOCKPOT

SPECIFICATION

Model | WL-CD-7K |

Voltage | 380 V |

Power | 7KVA |

Energy Storage | 4500J |

Capacitance | 40500uF |

Pressurization | 1000kg |

Electrode Stroke | 80 mm |

Closure | 180-280mm |

Platform Distance | 250mm |

Electrode Distance | 320-420mm |

Cooling Water | 3 Lit/min |

APPLICATION

Be able to applied to cookware industry for pan , cup , pot handle welding.

FEATURE

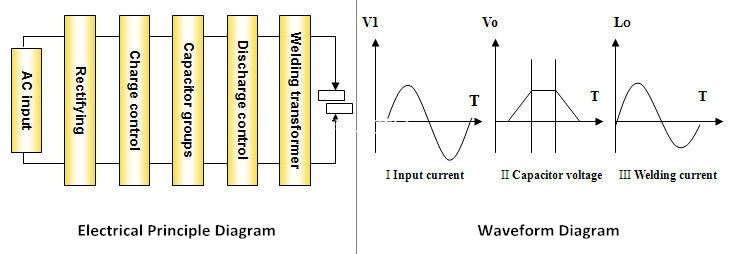

1.Power Source: The design uses 7K capacitor discharge method as welding power source. Adopt Japanese "NIPPON CHEMI CON" high quality brand urgent charge-discharge special capacitor; High-speed charging and discharging voltage circuit, and fast charge-discharge special capacitance. Every minute charge-discharge cycle count as to 124 times (set to 100V) with quick speed, high efficiency; Digital adjustment of electric voltage, adjustable voltage from 0 to 425V. Accuracy for fluctuation is 1v which can help to guarantee the welding accuracy.

2. Welding control system: It used advanced microcomputer rapid response touch controller, digital control, simple and clear operate interface; Quick thinking logic circuit, can guarantee the voltage for each discharge must reach the preset voltage then it can work, which can ensure the stability of the welding effect. It can effectively prevent the unhealthy phenomenon of loose weld and cold joint; Speed reaction, high accuracy control, provide guarantee for high quality welding spot.

3. Main Engine Control System: Adopt the touch screen of Japan Panasonic as the human-machine interface, Chinese-English input. The PLC, as the control hub as the whole machine, is in charge of reading, transmitting and controlling all kinds of signal processing and coordinating with various external instructing transmission signal mechanism in order to ensure the validity of all orders of execution of the machine. The self-detection of all automatic testing stations effectively eradicates the occurrence of malfunction and other accidents. When the pressure, current, air pressure, hydraulic pressure, temperature or other testing signals are in abnormal situation, the machine will give an alarm to prevent any insecure accidents.

DESCRIPTION

WL - CD - 7K, which is suitable for single handle one-off spot welding, handles of pot welding and other single spot welding opposite or multi-spot welding workpiece one-off welding. Good welding for the general kitchenware industry products.

MATERIAL CONFIGURATION

1. Adopt the energy storage type quick charge-discharge capacitor from Japan Nippon Chemi-Con (NCC) which is originated from MARGON or HITACHI; Fast discharge rate. Stable performance.

2. Adopt SEMIKON from West Germany, IXYS or IR Silicon controlled from United States. High precision and durable. Be able to achieve high stable control on the magnitude of current.

3. Adopt Motorola integrated circuits from United States. Quick response. Stable performance.

4. Adopt pneumatic parts from Japan or Taiwan with reliable performance.

5. All the devices are from imported famous brands with ideal service life and performance.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.