GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Aluminum Products Pneumatic Spot Welding Machine / Copper

Projection Welding

DESCRIPTION

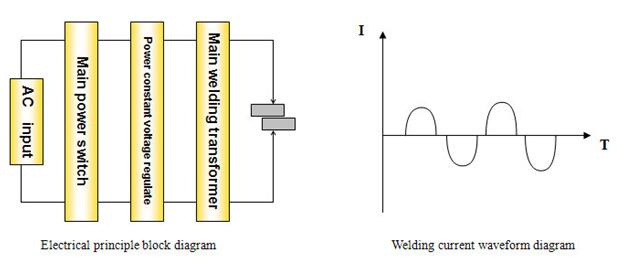

Under the operation of transformer, pneumatic AC pulse spot welder

utilizes the general mains supply to lower the voltage and increase

the electric current. Such kind of low voltage but large current

will be transmitted from the electrode to the linked point of two

work pieces. On the linkage, due to the resistance of work piece,

high temperature will occur so the metal will therefore generates

high heat to make the work pieces in molten condition. Thus, the

purpose of welding the two work pieces is achieved. The power of

the pneumatic AC pulse spot welder that we produce is from 3KVA to

600KVA. It can be used to weld 10mm of iron and metals like

stainless steel. Applicable to all kinds of hardware.

FEATURE

1. Welding Control System: The AC pulse spot welder that we produce

can be matched with many types of welding controllers.

WD-KD5: Intelligent microcomputer control; Multiple-section of

discharge; It can be used to preheat, to weld, to reshape or to

temper for special materials; Solve the problems of void welding or

loose welding due to current shunt during the process of multiple

projection welding; Especially suitable for welding high-carbon

steel or special interlayer of metal plate; When the voltage of

power supply is fluctuated, it can automatically compensate the

current to weld.

2. Silicon Controlled: Adopt the SEMIKRON from West Germany, IXYS

or IR Silicon controlled from United States; High precision and

durable; Be able to control the high stability of the magnitude of

current.

3.Pneumatic Control System:Adopt large displacement of magnetic

valve and gas assembly, sufficient air supply; Adopt the quick

exhaust cylinder, quick response, good servo performance.

4. Welding Transformer: Adopt high purity silicon steel disc

refined welding transformer; Good performance in permeability and

electrical conductivity; Less consumption of electricity, the

contribution of our welding machine is 15% higher than the other

machines of the same quality from the same industry. Be able to

weld the metal plates like 8mm+8mm low-carbon steel.

5. Safety in Use: Strictly implement the security standard of China

Compulsory Certification and CE of European Community.

SPECIFICATION

Model | Input | Input | Output Current | Pressurization | Electrode | Closure | Platform | Electrode | Cooling | |

V | KVA | A | kg | mm | mm | mm | mm | Lit/Min | ||

WL-S-16K | 380/1 | 16 | 10000 | 300 | 80 | - | - | - | 6 | |

WL-S-25K | 25 | 12000 | 300 | 80 | - | - | - | 6 | ||

WL-S-35K | 35 | 16000 | 350 | 80 | - | - | - | 6 | ||

WL-S-50K | 50 | 19500 | 500 | 80 | - | - | - | 6 | ||

WL-SP-25K | 25 | 12000 | 300 | 80 | 145-225 | 250 | 320-420 | 6 | ||

WL-SP-35K | 50 | 16000 | 350 | 80 | 145-225 | 250 | 320-420 | 6 | ||

WL-SP-50K | 50 | 19500 | 500 | 80 | 145-225 | 250 | 320-420 | 6 | ||

WL-SP-75K | 75 | 24000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 | ||

WL-SP-100K | 100 | 34000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 |

APPLICATION

Iron wire products, hardware decorative lighting, kitchen utensils,

automobile industry, small household appliances, small hardware,

etc.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding

industry in China for 20 years; Factory direct

sale, competitive price.

2. Customized Service: We can help to design and develop

the welding machine according to your requirement. We are

flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months

warranty. Our machines are strictly complied with ISO9001:2000 and

China Compulsory Certification. Most of our machines enjoy 8-10

years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours

technical support by email. Our professional team is

always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time

delivery.

6. Prompt Response to Customers: Your satisfaction is the

goal we pursue.