GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Glass Lid Stainless Steel Belt Welding Machine

SPECIFICATION

Model | WL-C-15K |

Voltage | 380 V |

Power | 15KVA |

Energy Storage | 8000J |

Capacitance | 73500uF |

Pressurization | 1500kg |

Electrode Stroke | 100 mm |

Closure | 130-230mm |

Platform Distance | 260mm |

Electrode Distance | 490-540mm |

Cooling Water | 6 Lit/min |

APPLICATION

Specialize in welding of glass lid steel belt (within 50mm width)

DESCRIPTION

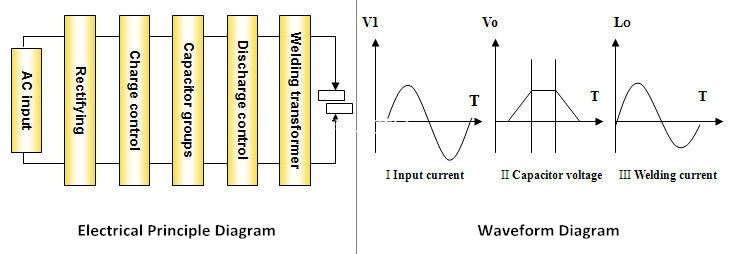

1. The machine is designed to use 15K (8000J) capacitor discharge method as welding power source. Adopt Japanese "NIPPON CHEMI CON"(NCC225UF/475V)high quality brand urgent charge-discharge special capacitor; High-speed charging and discharging voltage circuit, and fast charge-discharge special capacitance. Every minute charge-discharge cycle count as to 124 times (set to 100V) with quick speed, high efficiency; Digital adjustment of electric voltage, adjustable voltage from 0 to 425V. Accuracy for fluctuation is 1v which can help to guarantee the welding accuracy.

2. Advantage of automatic fixture: the fixture could do overlapping of material automatically so as to prevent easy cracking by manual overlapping. Increase production efficiency.

3. Advantage of automatic grinding device: The electrode is consumable parts which needs to be grinded some time after using. With this device, you do not need to take out electrode everytime for grinding. The machine will do grinding on the electrode automatically after the preset number of time of using.

MATERIAL CONFIGURATION

S.N. | Name | Specification | Brand | Origin |

1 | Charging silicon controlled | KP-150 | MCC | U.S.A |

2 | Discharging silicon controlled | SKKT1000-12E | MCC | U.S.A |

3 | Rectifier diode | ZP-150A | MCC | U.S.A |

4 | Current-limiting resistance | 100W/100Ω | NANFA | Hong Kong |

5 | Capacitance | 225UF/475V | Nitponchemi.con | Japan |

6 | Discharging contactor | JMC-75 | LG | South Korea |

7 | Charging contactor | JMC-18 | LG | South Korea |

8 | Charging control panel | WD-20DC-1 | HWASHI | Home-made |

9 | Discharging control panel | WD-20DC-2 | HWASHI | Home-made |

10 | Charging switch | 15A | MITSUBISHI | Japan |

11 | Tail switch | DS-231 | IDEC | Japan |

12 | The main magnetic valve | 3000# | SANWO | Korea |

13 | Pressing magnetic valve | 4# | SANWO | Korea |

14 | Air group | 4000# | SANWO | Korea |

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.

Steel Belt Welding Machine+Automatic Fixture+Automatic Electrode Grinding Device

Steel Belt Welding Machine+Automatic Fixture Steel Belt Welding Machine+Manual Fixture