GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

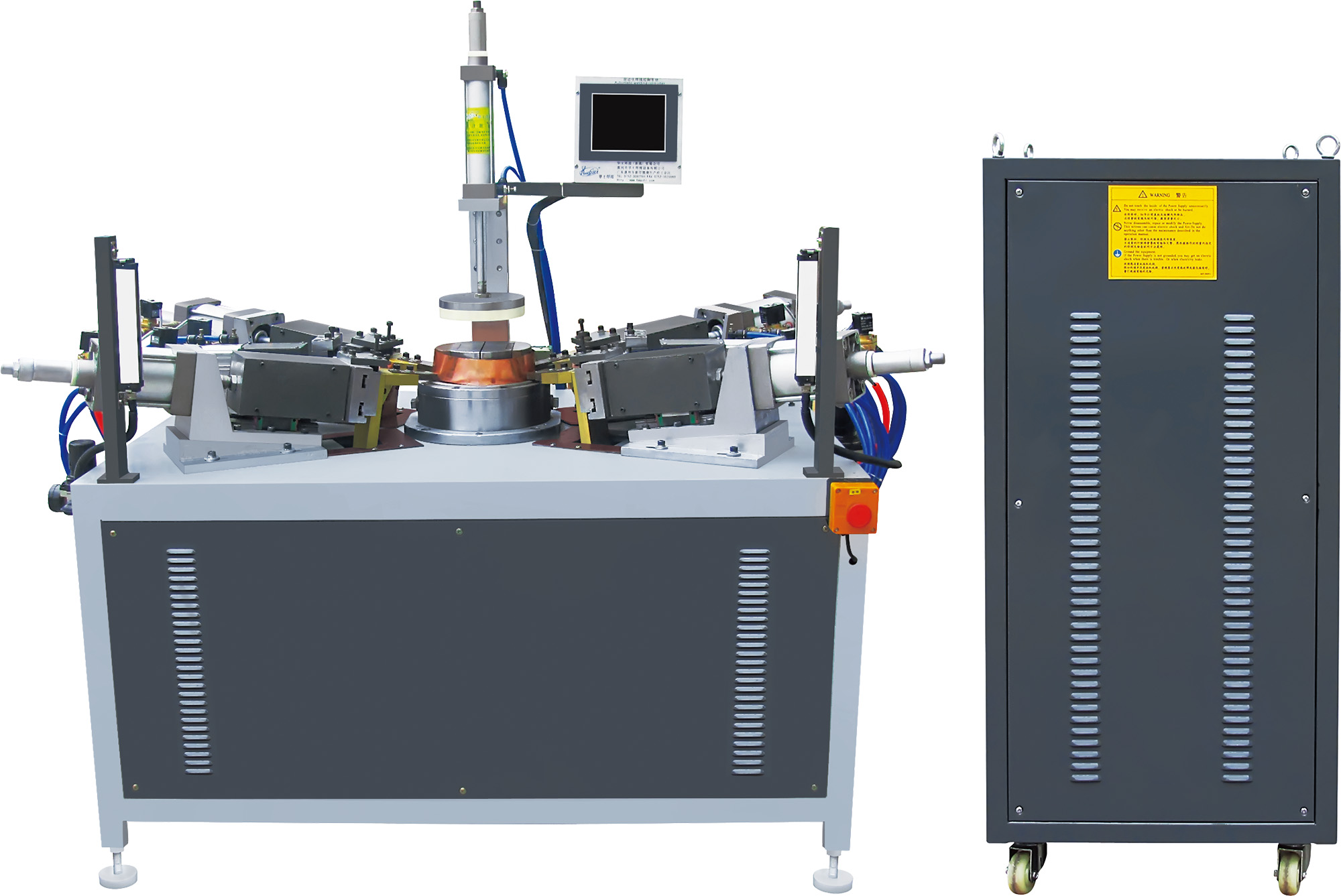

Capacitor Discharge Resistance Projection Welding Machine For Cookware Wire Handle

DESCRIPTION

Capacitor Discharge Resistance Welding is a special form of Resistance/ Projection welding in which the welding energy is provided by the release of energy stored from a large capacitor bank.

Since the CD resistance welding process utilizes stored energy rather than conventional processes which use direct demand on incoming power, the welding times are very short and concentrated, typically in 10 milliseconds or less. The resulting short welding time guarantees that the energy required to spot weld is concentrated in the weld zone, with a minimal if any heat affected zone or changes in the metallurgy of the work piece. Additionally, an upgraded power service to your building is often not needed as the high electrical energy required is not taken directly from the power distribution network but from a bank of capacitors, which stores the energy and recharges between welds.

The CD resistance welding process is ideal for quick and repeatable mass production processes that require tight dimensional tolerances. Capacitor discharge resistance welding is ideal for projection, press-fit and annular ring projections up to 4.5″ in diameter. Low marking welds can be better achieved due to the small heat affected zone and dissimilar metals that can often not be welded using conventional resistance welding can be successfully welded using capacitive discharge resistance welding.

Capacitor Discharge Resistance Welding is ideal for mass produced products in the automotive, appliance, electrical sectors and more.

SPECIFICATION

| No. | Item | Specification |

| 1 | Input Power Voltage (Customized) | Three-Phase 380V, 50HZ |

| 2 | Input Power | 15KVA |

| 3 | Welding Transformer | 300KVA |

| 4 | Capacitance | 70000UF |

| 5 | Max. Welding Heat | 10KJ |

| 6 | Max. Working Pressure | 2000N |

| 7 | Max. Open Distance Of Welding Platform | (Big)330mm; (Small)230mm |

| 8 | Electrode Holder | (Big)¢80mm;(Small)¢65mm |

| 9 | Electrode Base | (Big)¢40mm;(Small)¢32mm |

| 10 | Welding Cylinder | (Big)¢200mm;(Small)¢100mm; |

| 11 | Max. Air Pressure | ≥0.8mpa |

| 12 | Max. Air Flow | ≥45L/Min |

| 13 | Cooling Water Flow(optional) | ≥8L/Min |

| 14 | Main Body Covering Space | 1700x1000mm |

| 15 | Electric Box Covering Space | 1100x680mm |

OTHER APPLICATION

|

|

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.