Active Member

|

[China]

Address: No.6, Industry North Road, Songshan Lake high tech Industrial Development Zone, Dongguan, PRC

Contact name:Marcos

Guangdong Pudian Automation Technology Co., Ltd |

|

Platform Type Intermediate-Frequency Inverter Seamless Spot Welding Machine For Electrical Switch

Platform Type Intermediate-Frequency Inverter Seamless Spot Welding

Machine , Spot Welding Machine projection welding machine with

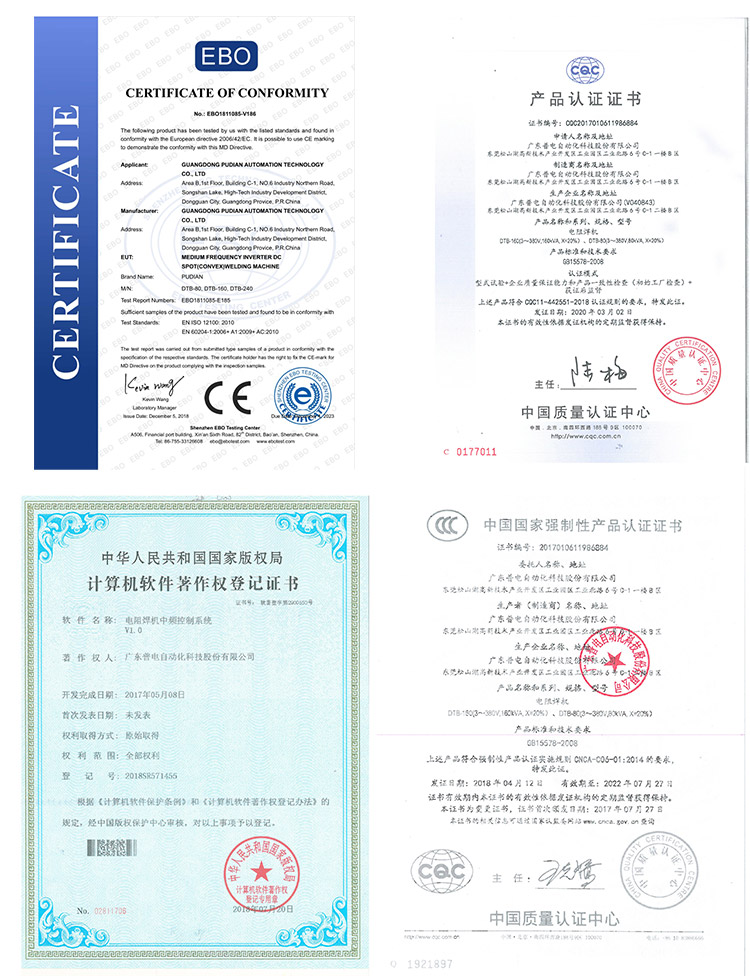

CE/CCC/ISO certificate

Description:

The product has passed the patent certification of China Intellectual Property Office, obtained China CCC certification and export CE certification. It is mainly used in the welding of metal large workpiece products in sheet metal industry, chassis and cabinet, elevator industry, metal door plate, hardware household appliances and other industries. It is applicable to the welding of metal materials such as aluminum, galvanized sheet, stainless steel and low carbon steel, with good performance and high welding quality.

Specifications

| parameter | DB-170W |

| Rated capacity | 170KVA |

| Input power | 3φ380V |

| Torch length | 390mm |

| short-circuit current | 22000A |

| Load duration | 20% |

| Electrode pressure | 2000N |

| Welding capacity / mild steel | 3.0+3.0mm |

| Welding capacity / aluminum plate | 2.0+2.0mm |

| air pressure | 0.6Mpa |

| weight | 760kg |

| Overall dimension | 1550×1000×2329mm |

| Table size | 1000×800mm(table size can be customized according to user requirements) |

Large platform, convenient for supporting, taking and placing workpieces; Multi joint flexible welding arm to meet the welding of products in different directions; Small impression on the back of the welding spot and high quality of the welding surface, eliminating the grinding process; Necessary for welding large metal workpieces.

Feature

01.The medium frequency inverter welding power supply is adopted to

effectively reduce power consumption and welding spatter, and the

welding quality is stable and reliable.

02.It can make your equipment management convenient, improve

product quality, improve work efficiency, reduce labor intensity

and improve production environment.

03.Using pneumatic pressurization can reduce the labor intensity of

workers, obtain constant spot welding pressure and make the welding

joints balanced and consistent. When welding iron cabinet, console

and other similar parts, there are no welding pits on the outer

surface of the parts, which improves the product quality.

04.The lower electrode is a forged chromium zirconium copper

horizontal worktable. The workpiece can be directly placed on the

worktable. It is simple to operate and easy to use. It can be

easily operated without special skills or experience.

05.The output current is DC, the current is smooth, and the

inductive reactance is zero.

06.The wide welding platform can realize electric lifting, which is

convenient for taking and placing workpieces.

07.The outer surface of the solder joint is smooth without solder

joint, deformation, grinding treatment and secondary processing

dust. This not only saves the subsequent treatment process,

improves the production efficiency, but also improves the working

environment (no noise and dust pollution).

Application

It is especially suitable for the welding of metal materials

such as aluminum, galvanized sheet, stainless steel and carbon

steel. It is widely used in the welding of large workpiece products

such as chassis and cabinet, elevator metal door plate, Kitchenware

and hardware appliances in sheet metal industry.,The product has

passed the patent certification of China Intellectual Property

Office, China CCC certification and export CE certification

FAQ

1. When can you arrange shipment?

We usually arrange shipment within 15 days after getting deposit,

but customized machines should be more than 25 days. We always ship

by air and sea in the mean time.

2. Do you inspect the finished products?

Yes, Each step of production products will be came out inspection

by QC department before shipping.

3. Are you a factory?

Yes, We are a factory, all machine is made by ourselves and we can

provide customize service according to your requirement.

4. What does your factory produce?

We produce and export all kinds of automatic welding machine and

robots and relative parts. We can design machines according to your

requirements.