Shenzhen Eton Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

SMEMA Interface Fully Automatic Stencil Printer 55 Degree Squeegee Angle

Full Automatic vision smt solder stencil printer machine

General Description

Feature:

1. Standard SMEMA link port. able to connect with most market smt machine

2. NC slide way adjustment for conveyor width and speed.

3. SMEMA interface,

4. Dry-type, wet-type and vacuum-type with arbitrary combination for stencil cleaning system..

5. ETON self development Vision alignment system

6. Built-in software diagnosis system.

7. Standard stainless steel squeegee, unique design to improve the lifespan of squeegee blade.

Parts introduction:

Suspended print head with programmable pressure automatic adjustment system:

1. Programmable pressure automatic adjustment system support

visible pressure values of front and rear squeegees and ensures

accurate pressure control.

2. Pressures of front and rear squeegees are separately adjusted,

to compensate pressure imbalance caused by fatigue deformation of

squeegee to prevent from different printing quality in front and

rear.

PCB clamping and support system.

1. Magnetic pins;

2. PCB flexible side clamping system to ensure no bending and

deformation during PCB clamping

3. Elastic Z-direction pressing tablets (optional)

4. Flexible automatic pins(optional)

Automatic clean system

Dry-type, wet-type and vacuum-type with arbitrary combination for stencil cleaning system.

Technical Parameter

Model | ET-4035 |

Dimension(MM) | 1100(L)* 800(W)* 1400(H) |

Mass/weight | 600KG |

Board Dimension | Max:400*340mm Min:50*50mm |

PCB Warpage | Max.FPCB diagonal 1% |

Squeegee pressure | 0-10kg/cm2 |

Squeegee speed | 6-300mm/sec |

Squeegee angle | 550 (standard) |

Squeegee angle | Stainless steel standard,rubber squeegee |

Repeat position accuracy | ±0.01mm |

Printing accuracy | ±0.025mm |

Cycle time | ≤9s(excluding printing and clean) |

Power input | AC:220±10%, 50/60HZ, 3KW |

FPCB transport over plate height | 20mm |

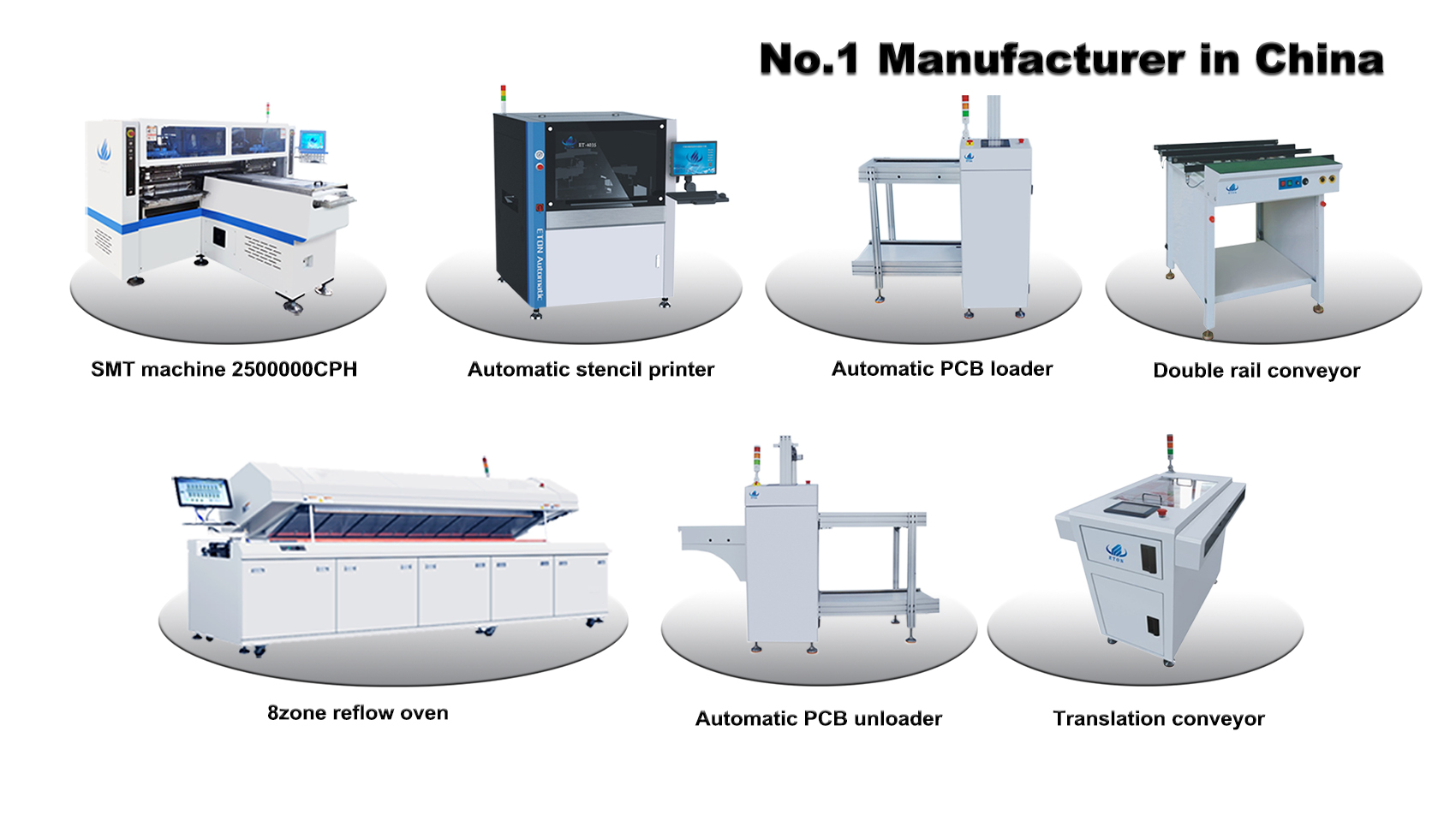

SMT production line equipments

We have full range of pick and place machine production line

equipment,So we have the professional suggestions for you to build

the production line.

Below are the suggestion of basic steps for the pick and place

progress and equipment

Main Products: SMT LED Pick and Place Machine,SMT LED Reflow

Oven,SMT LED Stencil Printer,SMT Production Line,LED Assembly

Line,SMT LED Machine.

Why choose us

Our company was established in 2011 with over 10years experiences in high-speed pick and place machine. We are the largest high tech manufacturer in China with strong capability of design ,R&D, manufacture, sales&services. “High efficiency””High quality”and “High Stability ” are he core technology of ETON. We got 9 invention Patents, 112 practical patents,12 software copyrights. Moreover, ETON has invented the fastest automatic pick and place machine with speed 250000CPH. We got large market share in USA, KOREA,INDIA, GERMANY,TURKEY more than 20 countries.We expanded our plant and built a new bigger industrial park in Jiangxi Province.

1. Efficient team: We provide the most systematic solution for you. The best suggestions of full SMT line equipment according to your budget and site.

2. Competitive price: We are directly manufacture of the ETON pick and place machine, so we can give you the best competitive price with high quality materials .

3. High quality: We have strictly quality control during all production from raw materials to the finished machine.

4. High efficiency : All machines parts are made by ourselves, so it’s convenient to control the time schedule and quality timely.

Packing

All machines are packed with vacuum and wooden packing like the one in the pictures.

Shipping: --- We ship to world wide from china mainland using air mail by EMS, UPS, DHL or

TNT or as your request for parts. --- Sea shipping for machine.

Step 1. Film packaging

Prevent the machine from dust ,water,crash and shaking

Step 2. Add foam+film packaging

Double safe protection,Prevent the machine from crash and shaking

Step 3. Unique tin foil packaging

Add tin foil packing can prevent the film from scratch broken.

Step 4. customized Strong wood carton packing

The customized strong wood packing for ocean ship,The machines are

fix oiin the wood carton, effectively prevent collision and shock.

For spare parts usually we’ll pack it separately with box.This is the packing reference for the feeders and some spare parts .

We got 9 invention Patents, 112 practical patents,12 software copyrights.

Electronic feeder feeding system.

Vision alignment flight identification, Mark correction.

Auto-optimization after coordinates generated ,etc.

Non-stop material re-loading function.

After sale service

Maintenance period 1year

One year warranty, during warranty, any parts need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, software is Reach and develop by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend different exhibition in different cities every year, at the same time, we will visit local clients and support our service and collect and feedback customer suggestions in time.

Provide latest information about technology and equipment

We give professional technology suggestion with our clients.And share the updates news to our clients

FQA

1. Q: Are you a trade company or a manufacturer?

We are an professional manufacturer specialized in Screen Printer,SMT Machine, Pick and Place Machine, Reflow Oven, SMT Production line and other SMT Products.

2. Q: What is your delivery date?

The delivery date is about 20 days upon the full payment.

3. Q: What is your payment terms?

100% payment before delivery or 50% deposit in advance and the rest before shipment.

4. Q: How is the warranty?

1. Every machine will be checked carefully before shipping out. Buyers should check the package once receiving.

2. The complete machine has a warranty period of 12 months from delivery and lifetime maintenance service.

3. We provide online Q/A and troubleshooting support and technical advice service. Provide one to one after-sale service.

5. What are your advantages?

Our company stick to five level management policy: sincere business, focus on R&D, manufacturing intentions, considerate service, customer trust

6. The products you are advertising are in stock?

A: The delivery date is about 20 days upon the full payment.Some times we have some in stock for ship , before shipping we’ll do some machine test for clients .

7. How can I buy this machine from you?

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.