Shenzhen Eton Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

1.product details

Producing with 2~4 types of materials with capacity at same time,

available for 5m,50m or any length of flexible strip and roll to

roll.

Dual-arm four modules with 17 nozzles for each mounting part, and

part A/B/C/D can be mounted separately or synchronously.

2.product Technical parameters of high speed pick and place machine

| Model number | HT-F9 |

| Dimension | 2700*2120*1550mm |

| PCB size | 1200*330~80*330mm |

| PCB thickness | 0.5~5mm |

| PCB clamping | adjustable pressure pneumatic |

| mounting mode | group to take and group to mount |

| system | windows 7 |

| display | touch screen monitor |

| input device | keyboard,mouse |

| NO.of camera | 5 sets of imported camera |

| mounting precision | ±0.03mm |

| mounting height | <13mm |

| mounting speed | 200000CPH |

| components | LED3014/3020/3528/5050 and resistors, capacitors, bridge rectifiers |

| components space | 0.2mm |

| NO.of feedings station | 68pcs |

| NO.of nozzles | 68pcs |

| power | 380AC 50HZ |

| power consumption | 6KW |

| operating environment | 23℃±3℃ |

| conveyor transmission | MAX length:1200mm |

| transmission speed | >500mm/sec |

| transmission direction | single(left→right,right→left) |

| transmission mode | online drive |

| position mode | optical |

| air pressure | >5.0kg/c㎡ |

| electrical control | independent research and development by ETON |

| motion control card module 1set | independent research and development by ETON |

| X.Y axis drive way | high-end magnetic linear motor+servo motor |

| feeding way | electric feeder with double motor |

3.product features of smt pick and place machine

4.Packing & shipping of smt mounter machine

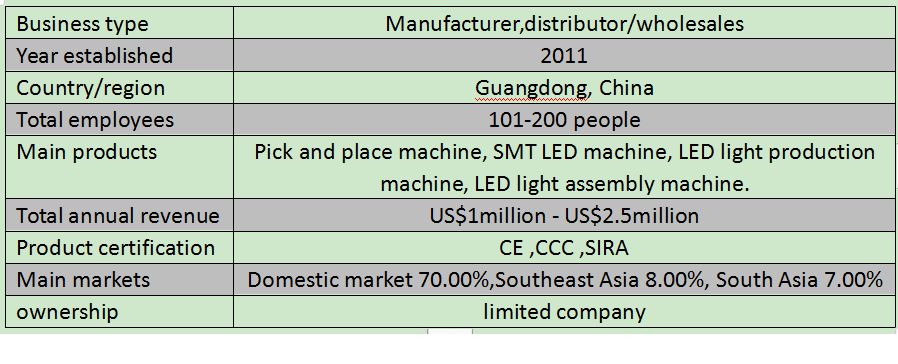

5.Company profile

6.Our Our certificates and certifications

7.our services

8. trade show

Industry related knowledge

A mounting machine consists of three parts: a mounting head, a

bearing mechanism and a servo system driven by X-Y coordinates. The

mount head is an intelligent manipulator, through the program

control, automatically correct the position, pick up the components

according to the requirements, accurately stick to the preset pad,

complete the three-dimensional reciprocating motion. It is the most

complex and critical part of the placement machine. The mounting

head of the placement machine is composed of suction nozzle, visual

alignment system, sensor and other components.

There are two kinds of mounting head: single head and long head,

and long head is divided into fixed type and rotary type. The

suction nozzle of the early single-head placement machine absorbs a

component, realizes the component alignment through the mechanical

alignment mechanism and gives the feeder a signal, so that the next

component enters the suction position. But the patch is slow, and

it usually takes 1 S. to attach a piece of components In order to

improve the speed of the patch, people adopt the method of

increasing the number of mount heads, that is, using multiple mount

heads to improve the speed of the patch. The multi-head placement

machine increased from single head to 3~6 mounting heads, no longer

using mechanical alignment, but improved to a variety of forms of

optical alignment, working separately absorb components, after the

alignment and then paste to the designated position of the PCB. At

present, the patch speed of this type of machine has reached the

level of 30,000 components per hour, and the price of this kind of

machine is low and can be used in combination. A rotating multihead

structure can also be used, and the current patch speed in this way

has reached ten thousand (4.5~5) per hour.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825