Shenzhen Eton Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Full automatic flexible side clamps MAX 520*350mm vision stencil printer

Description

1. PCB transport and clamping system

① The PCB loading direction can be selected and combined freely.

② Unique crafted internal gear conveyor belt to prevent jamming.

③ Programmable transport speed control makes PCB stop more precise.

④ Adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh.

⑤ The optimally designed module drive structure effectively improves the stability of the platform calibration, and realizes ultra-small transmission under fine-tuning, so that the machine can meet the printing requirement of higher precision. The structure is simple and reliable, the adjustable is convenient, and the height adjustment of the support PIN of the PCB board with different thicknesses can be quickly realized.

2. Stencil positioning system

① Arch bridge-shaped suspension hanging direct-connect scraper.

② The size of steel mesh is universal, with good and wide applicability.

③ Segmented fixed steel mesh frame.

3. Scraper system

① Cast aluminum scraper beam to ensure smoother running of scraper.

② Programmable suspension self-adjusting stepper motor drivers print head.

③ Bilateral double-slider positioning type slide rail structure ensures the accuracy and smoothness of running before and after printing.

④ According to the different pressure requirements of the front and rear squeegees and the stability of the lifting and lowering, to prevent the leakage of solder paste, the blade has a certain elastic clamping design, the pressure of the squeegee, the lifting speed, the printing speed, and the printing range are all software-adjustable. Provide a variety of demouding methods to meet different requirement of PCB, provide customers with a good printing control platform.

⑤ Slide rail type scraper system, improve operation stability and prolong lifetime.

⑥ The fully closed-loop scraper pressure feedback device monitors the scarper pressure at all times, making the printing more full.

⑦ Embedded scale,never fall off.

| Model | ET-5235 | |

| Screen Frames | Max Size | 737mm |

| Min Size | 470mm | |

| Thickness | 25-40mm | |

| PCB Size | MAX:520*350mm MIN:50*50mm | |

| Transport Height | 900±20mm | |

| Transport Direction | Left-Right; Right-Left; Left-Left;Right-Right | |

| Transport Speed | MAX 1200mm/s Programmable | |

| Print Head | Two independent direct-connect motor-driver printheads | |

| Squeegee Speed | 6-300mm/sec | |

| Cleaning System | Dry,Wet,Vacuum(Programmable) | |

| Printing Accuracy | ±0.025mm | |

| Cycle Time | ≤9s (Exclude Printing&Cleaning ) | |

| Power Input | AC:220±10%, 50/60HZ 1Φ 3KW | |

| Control Method | PC Control | |

| Dimension | 1240(L)*1450(W)*1650(H) | |

| Weight | Approx:700kg | |

| PCB Transfer Overhead Height | 10mm | |

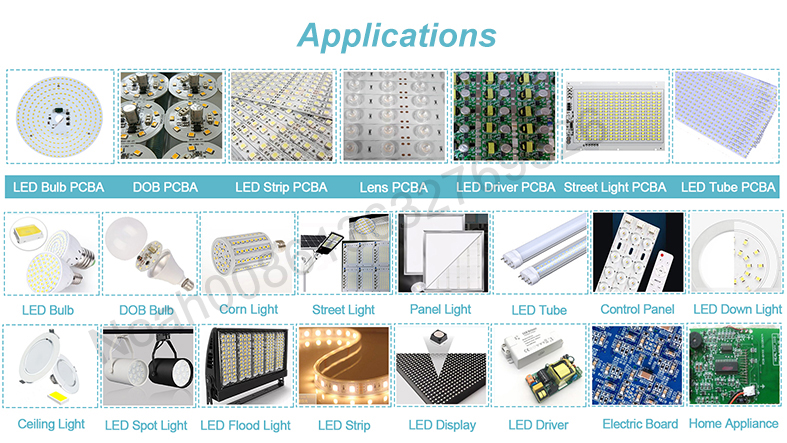

Machine application

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA,

etc.

Our Exhibitions

Participate in various exhibitions at home and abroad every year (except during the epidemic period)

Domestic exhibitions: Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED Light Exhibition, etc

FAQ

Q. What services can you provide?

A.

1)We provide whole line solution for our clients;

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com