Jiangsu Longdai Environmental Protection Co., Ltd. |

|

CF Type Water Treatment Video Technical Support Rotary Solid-Liquid Separator Mechanical Bar Screen Auto Operation

To Our Customers:

We engage in manufacturing almost all kinds of wastewater treatment equipments. Any question, please feel free to contact us. Thanks.

Application

CF type rotary solid-liquid separator, it is an advanced water treatment solid-liquid separation equipment, mainly used in urban sewage treatment plants, residential district sewage pretreatment, municipal rain/sewage pumping stations, water plants, and cooling water in power plants, etc. At the water inlet, the equipment is also widely used in water treatment projects in various industries such as textiles, printing and dyeing, food, aquatic products, papermaking, wine making, slaughter, tanning, etc.

Main Parameters and Installation Size Chart

| ModelNumber/Parameters | CF-500 | CF-600 | CF-700 | CF-800 | CF-900 | CF-1000 | CF-1100 | CF-1200 | CF-1300 | CF-1400 | CF-1500 | ||||

| Device width B(mm) | 500 | 600 | 700 | 800 | 006 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | ||||

| Channel Width B1(mm) | B+100 | ||||||||||||||

| Effective gate width B2(mm) | B-157 | ||||||||||||||

| Foundation bolt spacing B3(mm) | B+200 | ||||||||||||||

| Total equipment width B4(mm) | B+350 | ||||||||||||||

Rake tooth clearance b (mm) | t=100 | 1≤b≤10 | |||||||||||||

| t=150 | 10<b≤50 | ||||||||||||||

| Installation angle α(°) | 60~85 | ||||||||||||||

| Channel depth H(mm) | 800~12000 | ||||||||||||||

| Disport to platform height H1(mm) | 600~1200 | ||||||||||||||

| Total equipment height H2(mm) | H+H1+1500 | ||||||||||||||

Rear box frame height H3 (ww) | t=100 | ≈1000 | |||||||||||||

| t=150 | ~1100 | ||||||||||||||

Rake tooth running speed v (m/min) | ≈2.1 | ||||||||||||||

| power of motor N(kW) | 0.55~1.1 | 0.75~1.5 | 1.1~2.2 | 1.5~3.0 | |||||||||||

| head loss(mm) | ≤20(Without of blockage) | ||||||||||||||

| Civil engineering load | P1(KN) | 20 | 25 | ||||||||||||

| P2(KN) | 8 | 10 | |||||||||||||

| ΔP(KN) | 1.5 | 2.0 | |||||||||||||

Structure and Working Principle

The equipment adopts a rotary type. A special shape of plow-shaped rake teeth are arranged on the horizontal axis in a certain assembly sequence and number to form a rake tooth chain. According to the flow of water, it is assembled into different gaps and installed in the pumping station or At the entrance of the water treatment system, when the driving device drives the rake chain to move from bottom to top, the sundries in the water are picked up by the rake chain, and the liquid flows through the bar gap. After the equipment rotates to the upper apex, the rake chain changes The running direction is moving from top to bottom. The material will fall off the rake teeth by its own weight. When the rake teeth turn from the reverse side to the bottom of the equipment, they will start another reciprocating continuous operation to continuously remove debris from the water. To achieve the purpose of solid-liquid separation.

Main Features

1. The driving device is directly driven by a cycloid pin wheel or a helical gear reducer motor, which has the characteristics of low noise, compact structure and stable operation.

2. The frame is an integral frame structure, with strong rigidity, easy installation and less daily maintenance work.

3. There are two specifications of rake teeth, the pitch of the rake teeth t=150mm, and the pitch of the rake teeth t=100mm.

4. The equipment is easy to operate, and the operation of the equipment can be directly controlled locally/remotely.

5. In order to prevent accidental overload, it is equipped with mechanical shear pin and overcurrent accumulated weight protection to make the equipment operation safe and reliable.

6. When the equipment is 1500mm wide, in order to ensure the overall strength of the equipment, the parallel connection mode will be adopted.

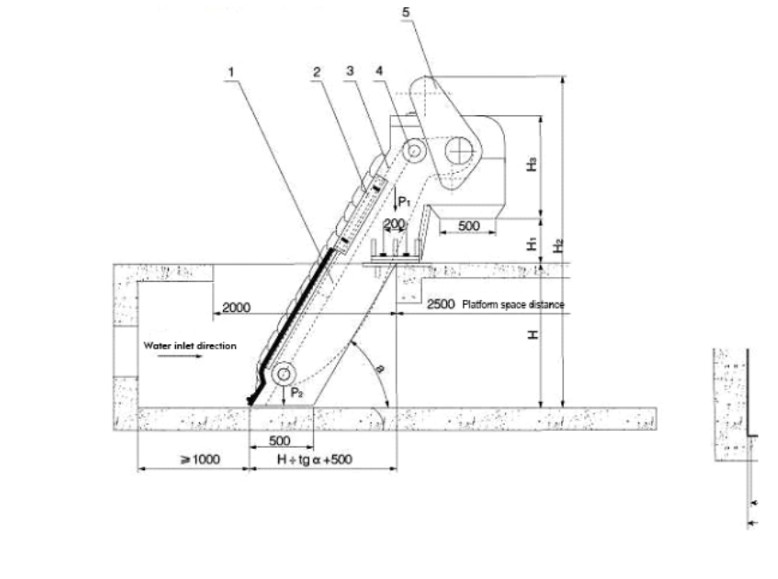

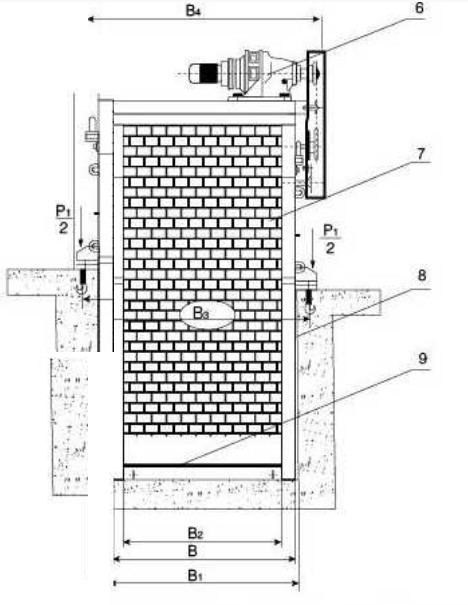

Outline and Installation Chart

Technical Requirements

1. Frame 2. manhole cover 3.hauling chain 4. Guide Device 5. Motor Shield 6. Drive Device 7. Rake Teeth 8. baffle(left and right) 9. baffle(top and bottom)

Packing and Delivery

1. Waterproof packing with the international export standard by

20ft, 40ft, 40hp container. Equipment Fittings, Electric Motor and

Power Cabinet will be packed in Wooden Case or Iron Box. Other

Equipment will be packed by Color-Stripes Plastic Cloth.

2. The whole plant machinery size are large as normal, so we will

use Waterproof cloth to pack all of them. The motor, gear box or

other easily damaged parts, we will put them into box. We have a

professional shipping department, they will try their best to save

your container quantity.

FAQ:

Q: Are You Trading Company Or Manufacture?

A: We Are Both Manufacture And Trading Company. We Have Over 30

Years' Professional Experience As a Waste Water Treatment Equipment

Manufacturer And Engineering Service Enterprise.

Q : What Are Your Main Products?

A:Keywords :Sludge Dewatering Machine Equipment, Screw Type Sludge

Dewatering Press Sludge Screw Press, Dewatering Sludge Machine

Screw Press ,Sewage Treatment Equipment ,Sludge Treatment

Plant,Screw Press Sludge Dewatering ,Dewatering Sludge,Dewatering

Machine For Sludge, Dewatering Sludge Machine Screw Press, Rotary

Drum Bar Screens, Equipment DAF, DAF Price ,Dissolved Air Flotation

System Price, Sludge Shaftless Screw Conveyor,Chemical Dosing

Device ,MBBR Price,MBBR Media,Disc Diffuser, Polymer Preparation

Chemical Dosing System, and other customized machines.