Skymen Technology Corporation Limited |

|

Verified Suppliers

|

|

Table Top Large Ultrasonic Cleaner Ultrasonic Surgical Instrument Cleaning Bath 600W Super sonic Cleaner Ultrasonic stencil Cleaner 30L bike parts

Features:

JP-100S product specification:

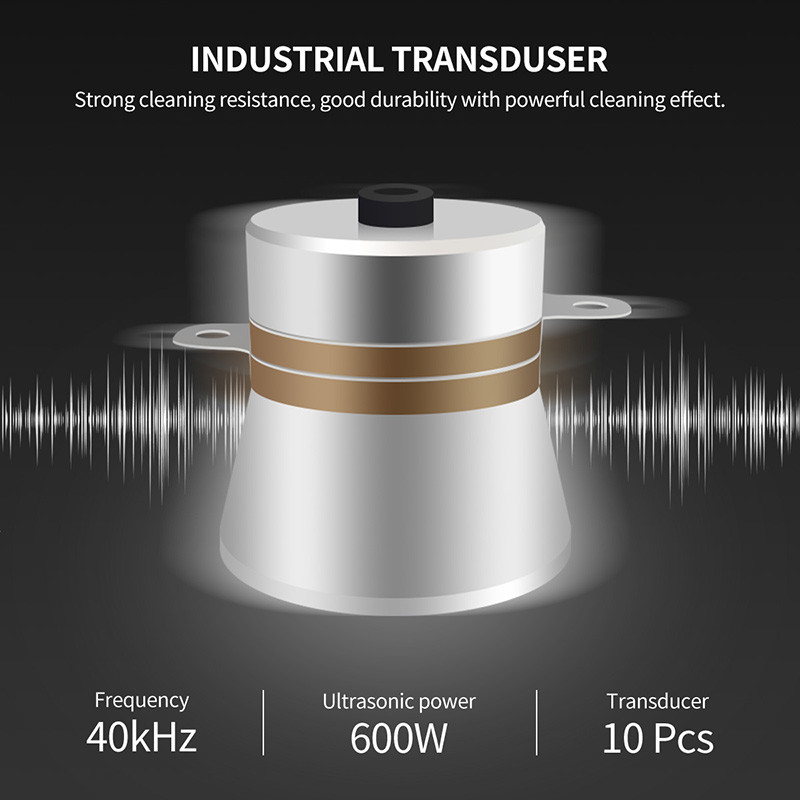

| Ultrasonic frequency | 40,000Hz |

| Material of tank | SUS304 |

| Material of shell | SUS304 |

| Capacity | 30L |

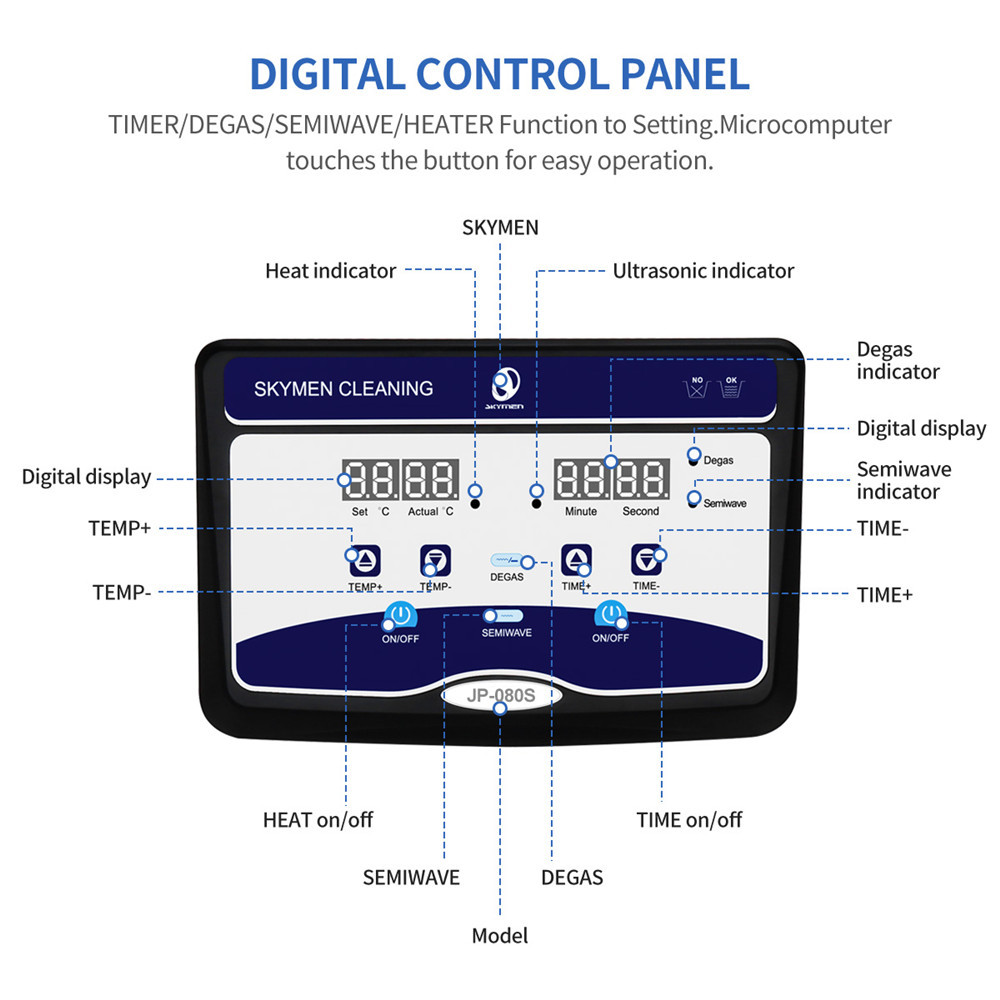

| Timer | Digital control, 0~30 mins |

| Heater | 500W |

| Power supply type 1 | AC 100~120V, 50/60Hz |

| Power supply type 2 | AC 220~240V, 50/60Hz |

| Ultrasonic power | 300W /600W |

| Tank inner dimension | 500*300*200mm |

| Unit dimension | 585*327*333mm |

| Inner Packing size | 635*410*390mm |

| Transducer | 10pcs |

| N.W. | 14.4kg |

| G.W. | 16kg |

| Certificate | SGS & CE & RoHS & FCC |

Images of this model:

Medical and surgical instruments in a variety of sizes and

complexity can pose challenges when it comes to cleaning,

disinfecting and sterilizing them after use. An ultrasonic cleaner

is an ideal tool for the first step in this three step process to

protect medical personnel and patients from possible infection due

to pathogens that remain on the instruments after a procedure.

Suggested Ultrasonic Cleaning Procedure

In all cases manufacturers’ instructions should be followed when using an ultrasonic cleaning process. These are representative steps.

Fill the ultrasonic cleaning tank with an approved medical instrument cleaning solution such as CLN-LR012 available from Tovatech following dilution instructions provided. Turn the cleaner on to start the degassing process. This step removes entrained air in new solutions that interferes with the efficiency of cavitation and takes approximately 10 minutes.

In the meantime:

At the end of the cycle, remove the instruments from the ultrasonic cleaning bath and thoroughly rinse them to remove all traces of the cleaning solution. Deionized water rinses will avoid spotting. If the instruments are not to be immediately disinfected and sterilized be certain that they are thoroughly dried and protected. Part reassembly can occur after sterilization.

Procedures should be in place to guide the replacement of used ultrasonic cleaning solutions. In some instances it is recommended that solution be drained and tanks thoroughly cleaned and dried after each ultrasonic cleaning cycle. Most solutions available today are biodegradable, which facilitates disposal but local authorities should be consulted on proper practices.

The ultrasonic cleaner uses ultrasonic waves (vibration) using

water with detergents or enzymatic products to break up soil and

organic material on medical instruments/devices. These devices are

rinsed then autoclaved (sterilized). The autoclave sterilizer uses

heat, steam, and pressure to kill all pathogenic microorganisms and

their spores.

Working priciple of Ultrasonic Cleaner

Package Includes:

1 x Digital Ultrasonic Cleaner

1 x Cleaning Basket

1 x Manual

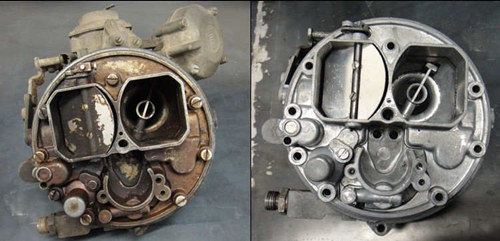

Cleaning effect: