Skymen Technology Corporation Limited |

|

Verified Suppliers

|

|

Skymen Ultrasonic Cleaner For Lawn Mowers Parts With 200W Heater 1.19 Gallon

Stainless Bench Top

| Model | Capacity | Tank Size | Ultrasonic Power | Heating Power | Frequency | Tank thickness | Material |

| (L) | (L*W*H)mm | (W) | (W) | (KHz) | (mm) | SUS304 | |

| JP-008 | 0.8 | 150*85*65 | 35 | 0 | 40 | 1 | SUS304 |

| JP-009 | 0.9 | 150*135*65 | 60 | 100 | 40 | 1 | SUS304 |

| JP-010T | 2 | 150*165*100 | 60 | 100 | 40 | 1 | SUS304 |

| JP-020S | 3.2 | 240*135*100 | 120 | 100 | 40 | 1 | SUS304 |

| JP-030S | 4.5 | 300*150*100 | 180 | 200 | 40 | 1 | SUS304 |

| JP-031S | 6.5 | 300*150*150 | 180 | 200 | 40 | 1 | SUS304 |

| JP-040S | 10 | 300*240*150 | 240 | 200 | 40 | 1 | SUS304 |

| JP-060S | 15 | 330*300*150 | 360 | 300 | 40 | 1 | SUS304 |

| JP-080S | 22 | 500*300*150 | 480 | 500 | 40 | 1 | SUS304 |

| JP-100S | 30 | 500*300*200 | 600 | 500 | 40 | 1 | SUS304 |

Product Show:

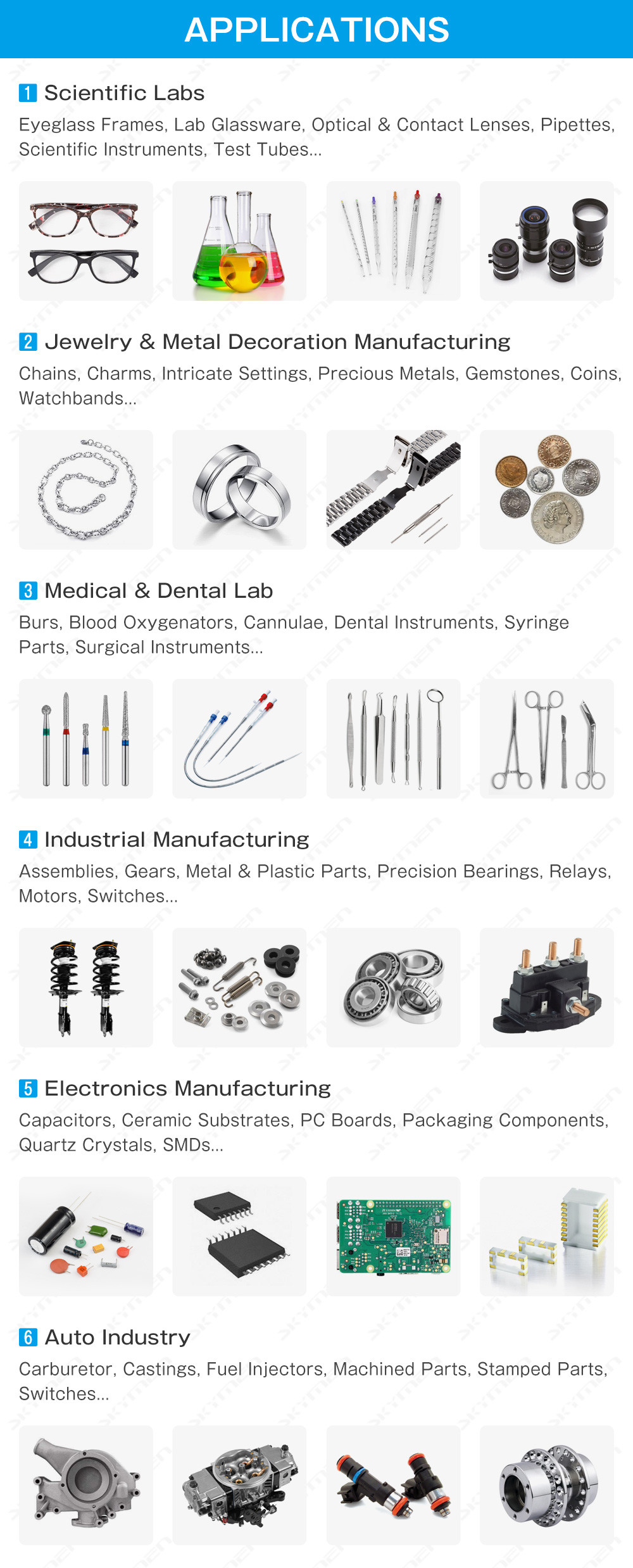

Application Area:

Industrial Ultrasonic Cleaning Machine

| Model | Capacity | Tank Size | Transducers | Ultrasonic Power | Heating Power | Tank thickness | Frequency |

| (L) | (L*W*H)mm | (pcs) | (W) | (W) | (mm) | (KHz) | |

| JP-120ST | 38 | 500X300X250 | 12 | 600 | 1500 | 2 | 28/40 |

| JP-180ST | 53 | 500X350X300 | 18 | 900 | 1500 | 2 | 28/40 |

| JP-240ST | 77 | 550X400X350 | 24 | 120 | 3000 | 2 | 28/40 |

| JP-300ST | 99 | 550X450X400 | 30 | 1500 | 3000 | 2 | 28/40 |

| JP-301ST | 99 | 800X300X400 | 30 | 1500 | 3000 | 2 | 28/40 |

| JP-360ST | 135 | 600X500X450 | 36 | 1800 | 4500 | 2 | 28/40 |

| JP-480ST | 175 | 700X500X500 | 48 | 2400 | 6000 | 2 | 28/40 |

| JP-600ST | 264 | 800X600X550 | 60 | 3000 | 6000 | 2 | 28/40 |

| JP-720ST | 360 | 1000X600X600 | 72 | 3600 | 9000 | 2 | 28/40 |

| JP-1108ST | 540 | 1000X900X600 | 108 | 5400 | 18000 | 2 | 28/40 |

| JP-1144ST | 960 | 1200X1000X800 | 144 | 7200 | 27000 | 2 | 28/40 |

| Model | Plate Size | Transducers | Ultrasonic Power | Generator | Suitable tank |

| (L*W*H)mm | (pcs) | (W) | (set) | (L) | |

| JP-1006I | 305*205*100 | 6 | 300 | 1 | 10~15 |

| JP-1012I | 355*305*100 | 12 | 600 | 1 | 30~40 |

| JP-1018I | 340*280*100 | 18 | 900 | 1 | 60~70 |

| JP-1024I | 430*280*100 | 24 | 1200 | 1 | 70~80 |

| JP-1030I | 460*370*100 | 30 | 1500 | 1 | 90~100 |

| JP-1036I | 550*450*100 | 36 | 1800 | 1 | 130~140 |

| JP-1048I | 600*450*100 | 48 | 2400 | 2 | 170~180 |

| Model | Tube Size | Transducers | Ultrasonic Power | Generator | Length of wire |

| (D*H)mm | (pcs) | (W) | (set) | (M) | |

| JM-1003 | 57*180 | 3 | 150 | 1 | 1.5 |

| JM-1006 | 57*300 | 6 | 300 | 1 | 1.5 |

| JM-1012 | 57*550 | 12 | 600 | 1 | 1.5 |

| JM-1018 | 57*750 | 18 | 900 | 1 | 1.5 |

| JM-1024 | 57*1000 | 24 | 1200 | 1 | 1.5 |

| JM-1036 | 57*1520 | 36 | 1800 | 1 |