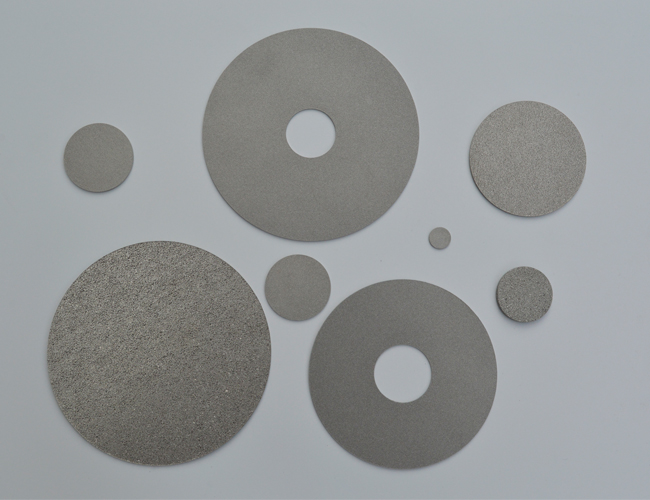

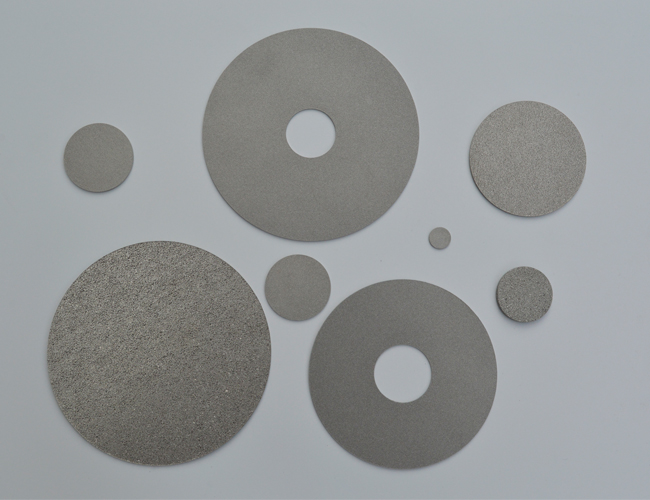

Factory Supply Micron Porosity Sintered Ss 316 Stainless Steel Disc

Filter For Pharmaceutical

Titanium sintered porous material is a kind of porous material with

high quality spherical and high purity titanium powder as raw

material and it is made rigid by forming and sintering at high

temperature.

Filtrate-- Isostatic compaction--Vacuum sintering

- Features of titanium sintered porous materials:

| Available Size Range Of Metal Sintered Products |

| Product | Max Length(Diameter) | Width(Diameter) | Thickness Range | Customized |

| Sintered Porous Plate | 800mm | 300mm | 0.5-2.2mm | Yes |

| Sintered Porous Disc | 300mm | 300mm | 0.5-2.2mm | Yes |

Application of titanium sintered porous materials

- Decarburization filtration of pharmaceutical liquids.

- Electrolytic gas industry precision filtration, gas distribution.

- The medical industry makes biological implants.

- Water treatment industry odor sterilization filtration and ozone

aeration.

- Clarification and filtration in food and beverage processing.

- Prefiltration of reverse osmosis system for electronics industry.

- High pressure air filtration in aerospace industry.

- Filtration and recovery of precious metal catalyst in fine chemical

industry.

- The electrode matrix of a fuel cell.

- Catalyst carrier in gas and liquid catalytic reactions.

- Precautions for the use of titanium sintered porous materials

- During installation, disassembly and clean avoid scratches,

collisions and falls on hard objects.

- Install correctly to avoid reverse filtering.

- Avoid instant pressurization when the filter element works.

- When the filtration efficiency is less than 50%, the filter element

should be cleaned in time.

- When cleaning the filter element, first backblow with pure gas,

backblow pressure is 1.5 times of the working pressure, each time

for 3-5 seconds, and 4-6 times, then backwash with clean liquid for

3-5 minutes, repeat 2-3 times.

- If the filter element is not good after online backblowing and

backwashing, it should be removed and cleaned in time.