Active Member

|

[China]

Address: Room 412, No.7, Zhongxin Road, Caier Industrial Zone, Donghuan Street, Shiqiao, Panyu District, Guangzhou City, Guangdong Province, China

Contact name:Tony

Guangzhou ZOSN Electrical Automation Co., LTD |

|

Fast Speed Side Sealer Shrink Wrap Machine

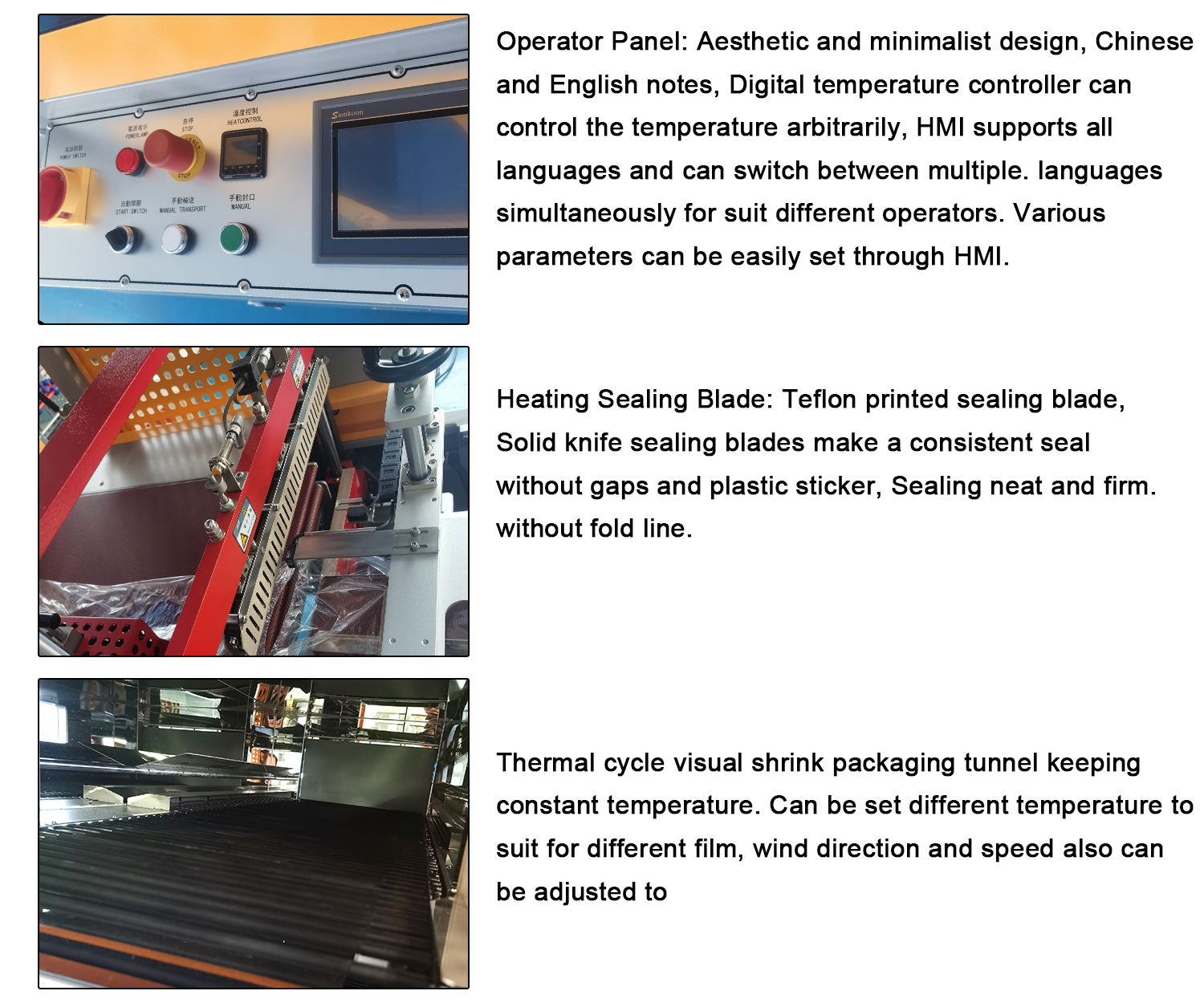

Product Feature

Applies to software, food, cosmetics, printing, pharmaceutical, flooring, ceramic, beverages, hardware other industries large quantities of shrink wrap.

1.Side sealing part can continuous pull film sealing and cutting,

the product length is unlimited.

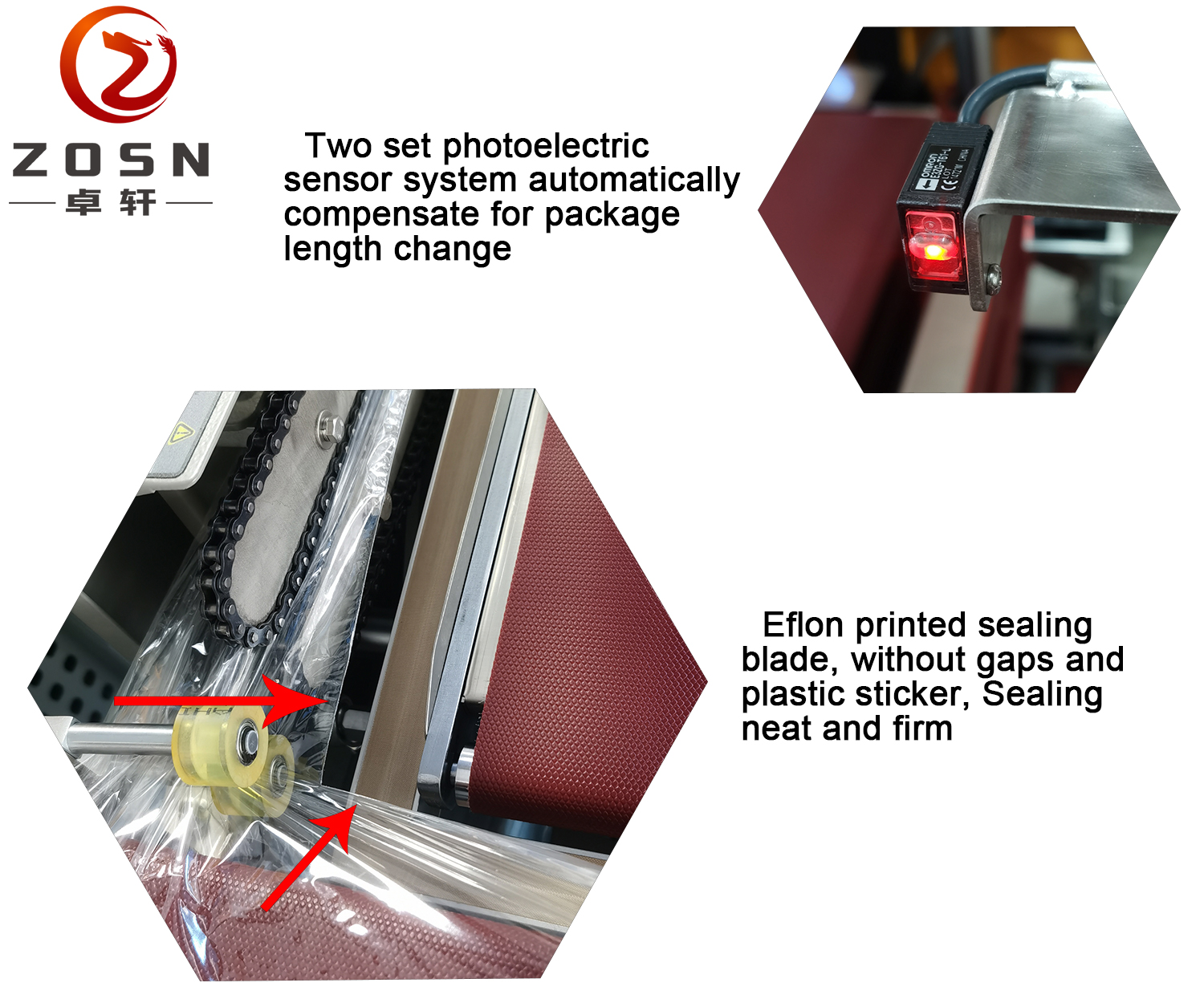

2.Feeding length controls through a combination of electric eye

detection and time relay to control precise film length that makes

it easier to control the contraction effect.

3.Waste film automatically rolling. Using independent motor

control, rolling speed uniform and smooth will not too tight or too

loose which can avoid break the waste film and the rewinding plate

is easy disassembly.

4.Adopt Mitsubishi PLC programmable controller and 7-inch man

machine interface, simple operation.

5.The sealing blade itself is equipped with automatic protection

function which effectively prevent from accidental cutting.

6.Automatic mode and manual mode can be switched at any time which

convenient to replace the shrink film.

7.The entire machine realizes unmanned operation with the

production line connecting.

Product Description

| Model | ZS-600T-CF | ZS-6030T |

| Power | 3.3kw | 18kw |

| Power Supply | AC 380/220V 3PH 50/60Hz | AC 380V 3PH 50/60Hz |

| Max Packing Sizes L×W×H | L(unlimited) / W+ H ≤ 500mm | 1200×450×200mm |

| Tunnel Size L×W×H | / | 1800×600×300mm |

| Sealing Blade Length | L 600mm / H180mm | / |

| Packing Speed | 20-50 Pcs / min. | 0-30m / min |

| External Air Source | 6-8kg / cm2 | |

| Shrink Film | POF | POF |

| Machine Size L×W×H | 1920×1710×1400mm | 2300×800×1560mm |

| Packaging Size L×W×H | 1970×1760×1530mm | 2360×860×1680mm |

| G./N. Weight | 820/760kgs | 360/300kgs |

Product Display

Standard Safety Performance

1. The transverse sealing knife is equipped with automatic

anti-wrong cutting product device.

2. There are protective devices or warning signs at unsafe

locations of the machine.

3. The machine is equipped with emergency stop control device, it

can stop working and restore all the organs to the initial state

after pressing the emergency stop switch.

Packaging Details

1. Spray anti-rust oil

2. Fix the machine on the pallet

3. The machine is also wrapped with stretch film and sponge pads,

prevent the machine from impact, moisture, dust

4. Covered with sea export plywood case.

5. Loading Port: Guangzhou or Shenzhen